What is a Warehouse Layout?

A warehouse layout is the arrangement of space, equipment, and goods to facilitate material movement. The layout influences the operations and minimises delays and maximises storage efficiency. An effective design has a direct impact on improving the efficiency of a supply chain by striking a balance between accessibility, speed and productivity.

Key Areas in Warehouse Design & Layout

All the warehouses need to concentrate on key areas to get a smooth flow. An efficient warehouse design and layout will incorporate the receipts, storage, picking, packing and dispatch sections. A good alignment of these zones contributes to the flow of operations in the warehouse and increases the efficiency of movement and storage in general.

Loading Zone

Any warehouse layout plan will need the loading zone because it guarantees the goods that have left the warehouse have been moved promptly. It should accommodate heavy vehicle traffic, offer safety conditions and reduce waiting time, and this is a major consideration in any cost reduction strategy in the warehouse.

Unloading Zone

The unloading area helps in rapid access of products into the store. Organised space helps minimise congestion, facilitates movement of goods in the warehouse, and maintains efficiency in material flow. The right planning here aids the reception operations and blends with the warehouse layout design process in an automatic manner.

Receiving Zone

Goods are inspected and logged into the receiving zone and then stored. It preconditions inventory management and productivity. Proper receiving areas facilitate acceptance processes that are easy to follow, resulting in a shorter turnaround time and accuracy to integrate the warehouse storage system.

Dispatch Zone

The dispatch zone plays a significant role in the delivery time, which affects customer satisfaction. An organised delivery will guarantee a quick transit and precise delivery. In this case, integration of order picking workflows can enable easier transitions between storage and transportation to enhance the flow of operations throughout the warehouse and minimise unnecessary handling.

Storage Area

A warehouse is centred on the storage space. It also maximises space, organises products logically, and makes the retrieval simple with the right warehouse storage systems. Optimising the space within warehouses is directly supported by efficient storage and helps to increase productivity by minimising search time and appropriate classification.

Order Picking Area

Most of the labour is utilised in the order picking area. Here efficiency is focused on a picking warehouse with a particular design. Streamlining the workflow is a sure way to improve accuracy, improve speed of operation, and save time on workers’ travel, with the overall effect of warehouse layout on productivity being enormous.

Packing Zone

The packing area concerns packing goods to be sent out. It helps to ensure precision and security of deliveries. An integrated design ensures a faster pace in packaging, aids in cost reduction strategies in the warehouse, and provides a more efficient flow of warehouse operational activities between logistics functions with a reliable, consistent outcome.

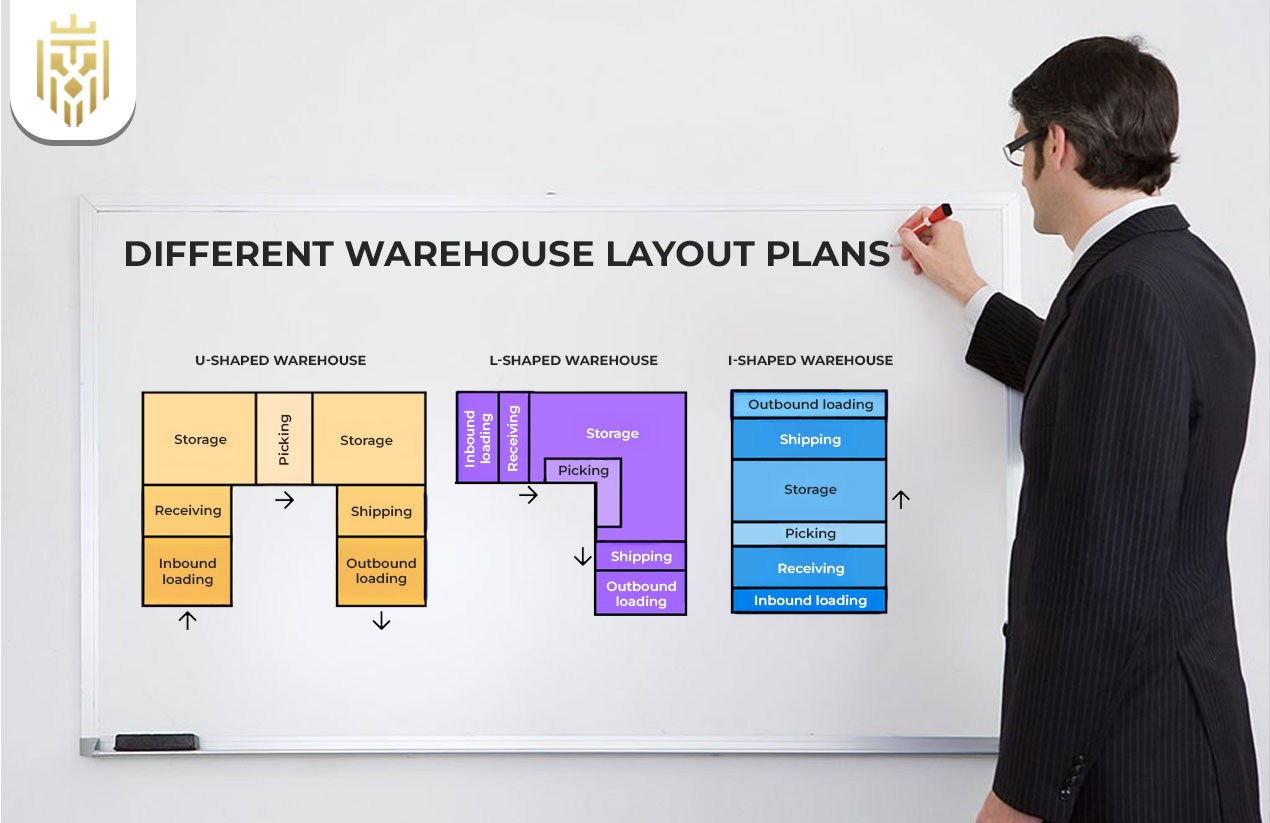

Different Warehouse Layout Plans

Various structural flows can be used according to goods and operations in a warehouse layout plan. The speed, space use, and movement of goods in the warehouse are affected by each format. To ensure optimal efficiency in their operations, businesses are required to use layouts that match volume, product type and processes.

U-Shaped Flow

U-shaped flow is one of the most common types of warehouse layout design, which promotes ease of entry and exit of goods. It consolidates storage, increases operational visibility and increases the efficiency of order picking and encourages compact space usage to promote reduced handling and movement speed.

L-Shaped Flow

L-shaped flow divides receiving and dispatch functions on two ends. This enhances the operations flow in the warehouse by minimising congestion and maximising movement. It is suitable for medium-sized facilities and is conducive to promoting safety, control, and improved alignment of goods with overall warehouse storage systems.

I-Shaped Flow

The I-shaped flow permits a streamlined flow of goods in the warehouse where there is a distinct separation of the goods receiving and dispatch areas. It is conducive to large-volume processes, minimises bottlenecks, and improves the efficiency of supply chains; hence, it applies to current large-scale distribution centres with bulk loads.

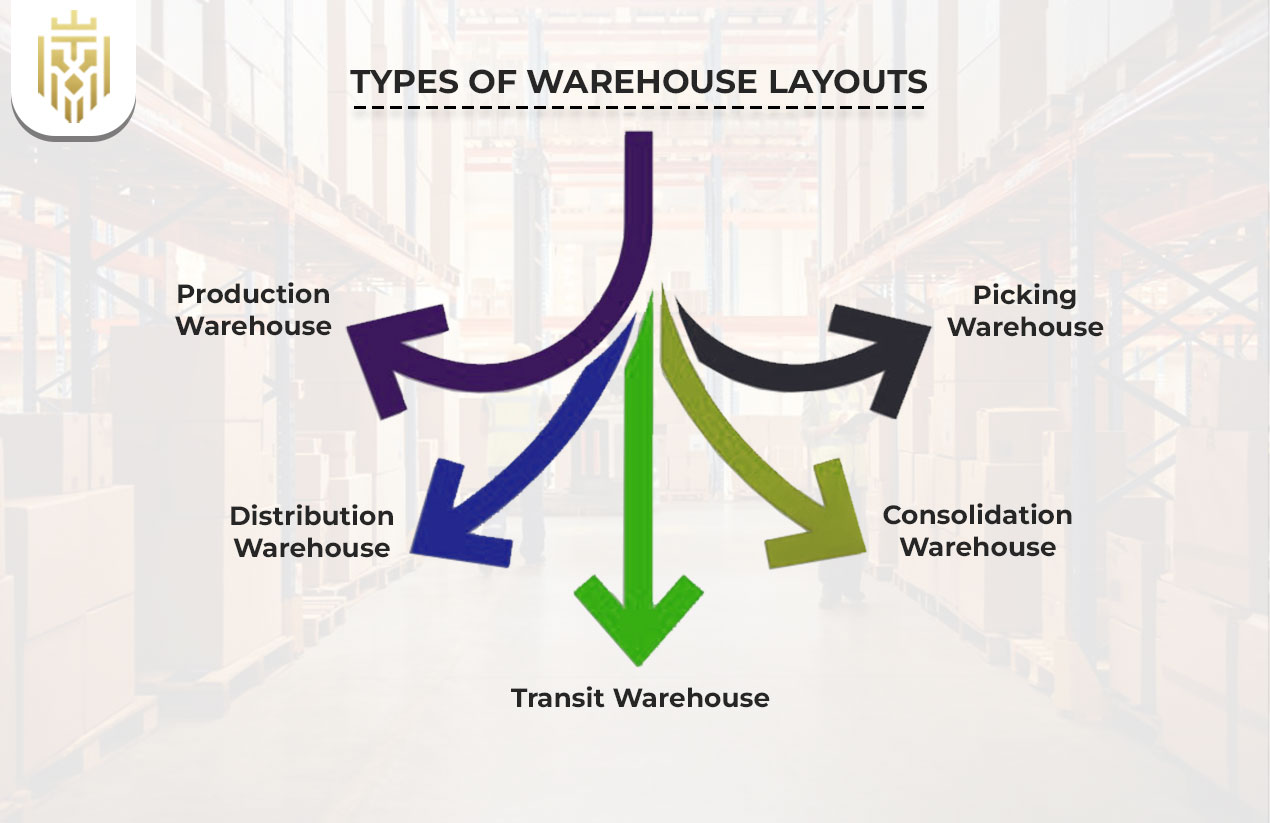

Types of Warehouse Layouts

Warehouse layout is decided according to the type of goods and the nature of operations. The design impacts on the space, movement and efficiency between production and transit and consolidation centres directly on cost, delivery times and the effect of warehouse design on overall productivity.

Production Warehouse

A production warehouse is used to back up manufacturing facilities by storing raw materials and finished goods. Efficient design and layout of the warehouse is a guarantee of easy integration into production cycles. This aids in the minimisation of downtime, inventory regulation and constant material flow to facilitate efficient processes in the industrial supply chain.

Distribution Warehouse

A distribution warehouse allows quick transportation of products to the customers and retailers. By emphasising warehouse storage mechanisms and optimal order picking, it minimises lead times. Efficiency in this case enhances efficiency in the improvement of the supply chain as a whole, and it is the core of contemporary e-commerce and retail logistics.

Transit Warehouse

Transit warehouses are used when goods are to be moved to a new destination in the short term. The design aims at optimising warehouse space to minimise holding costs. The layout of this type directly helps to make the transfer faster, which means that the work in the warehouse is conducted without any significant delays in the logistic system.

Consolidation Warehouse

A consolidation warehouse is a warehouse that consolidates shipments of two or more suppliers before delivery. A good warehouse layout design process facilitates smoother flow, lower costs and maximised handling. Such a type lowers transportation costs, optimises warehouse cost reduction measures, and achieves flexibility in meeting a wide variety of customer needs effectively.

Picking Warehouse

A picking warehouse is a warehouse related to picking orders and dispatching. It has a faster and more accurate warehouse layout, where workers move very little distance. Optimising such a design assists in inventory control, better goods flow in the warehouse, and customer satisfaction due to faster order processing.

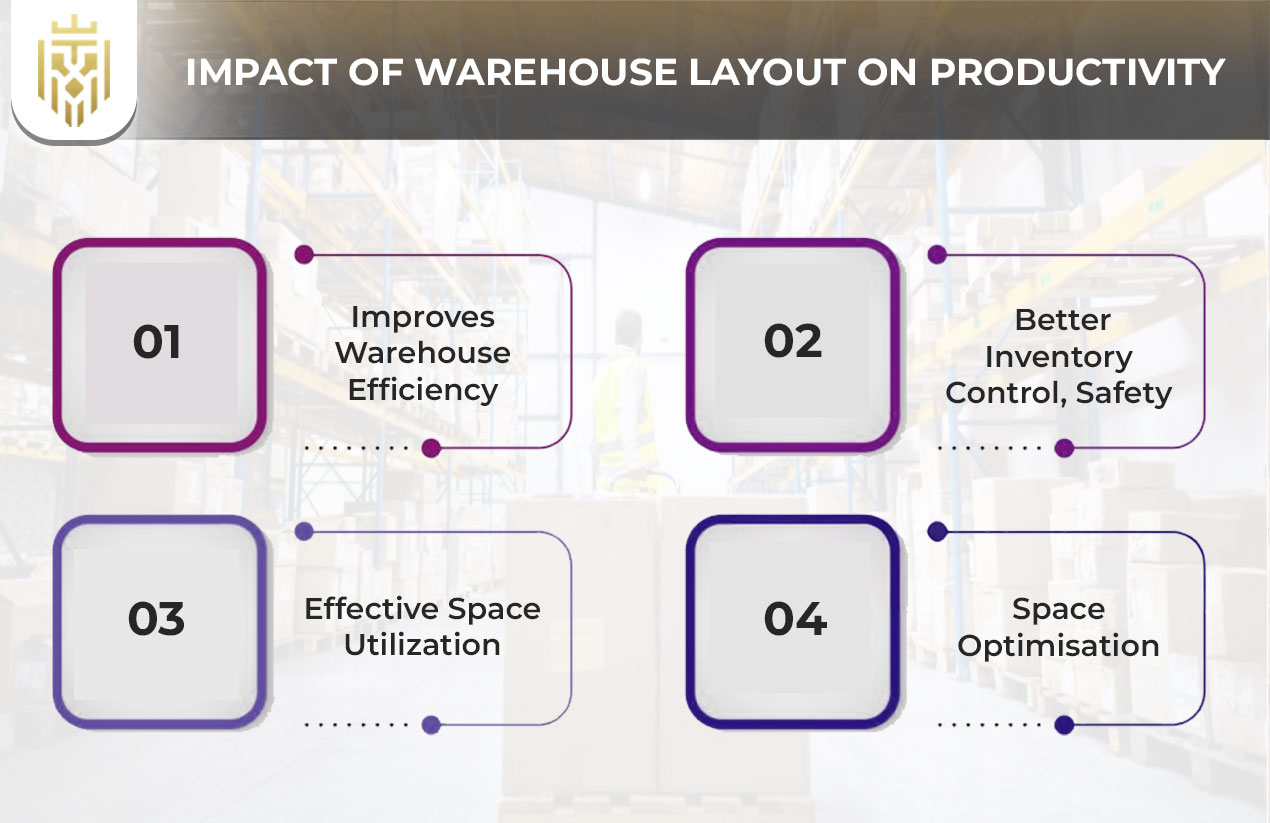

Impact of Warehouse Layout on Productivity

The warehouse layout and its effect on productivity cannot be ignored. Well-designed layouts reduce time and cost, whether it be storage and picking or providing faster dispatches. They have a direct impact on cost reduction policies in warehouses and safe, efficient and scalable logistics processes in all industries worldwide.

Improves Warehouse Efficiency

Organised design saves time on travelling and increases mechanical mobility of materials and storage. Optimisation of the warehouse layout plan provides a more streamlined working process and handling. These enhancements lead to efficiency improvement in the supply chain, shorten delays, and foster productivity through the alignment of workers, goods, and space.

Better Inventory Control

An accurately designed warehouse makes it possible to have more robust inventory control systems. Effective warehouse storage allows real-time tracking, error reduction, and product visibility. This positively impacts operational accuracy and warehouse layout design procedure and fortifies the productivity of contemporary supply chain activities.

Safety

There is enhanced safety through clear areas, safe movement of materials, and designed warehouse operational flow. Structured designs minimise accidents and ensure the safety of the workers and the security of the goods. A safe environment is not only compliant but also essential to long-term sustainable efficiency and cost reduction strategies in the warehouse.

Effective Space Utilization

When properly used, every square foot is utilised to the fullest extent. Effective warehouse space optimisation will facilitate increased density of storage with no disruption of movement. The intelligent design is in line with the current warehouse storage architecture, where scalability is ensured at a low operating cost and high productivity of both distribution and consolidation facilities.

Space Optimisation

Warehouse space optimisation minimises space wastage and thereby enhances handling of materials. It is necessary to guarantee efficient moving of goods in the warehouse, accurately pick orders and maximise returns. Here, layout optimisation also supports improvement of the supply chain in addition to reducing the storage and operating costs to a minimum.

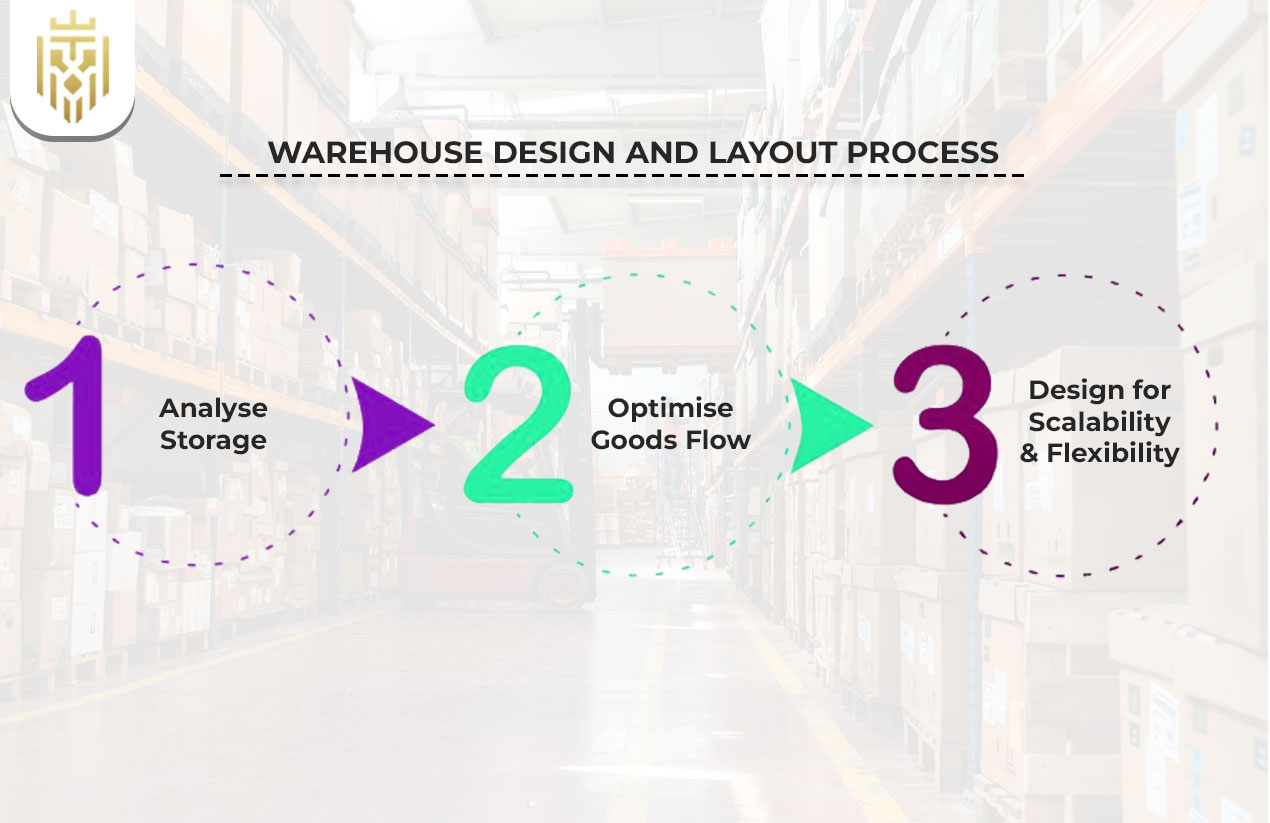

Warehouse Design and Layout Process

Designing warehouse layout is a process that comprises analysing storage needs, flow optimisation, and scalability design. An organised strategy increases efficiency, allows cost reduction strategies in the warehouse, and increases flexibility to make sure that the facilities address evolving needs and help maintain overall warehouse layout influence on productivity at all times.

Analyse Storage

Storage analysis makes the appropriate warehouse storage systems a reality. Planning is affected by factors such as volume, type of product and season. Proper positioning is beneficial in terms of maximising warehouse space, minimising error, and enhancing efficiency in addition to supporting more intelligent warehouse cost reduction initiatives to remain competitive in the long run.

Optimise Goods Flow

The flow of goods in the warehouse is optimised to minimise time spent in handling, enhance the operational flow in the warehouse, and synchronise the zones to achieve minimal congestion. Regular and seamless flow of receiving, storage and dispatch guarantees productivity and can effectively support scalable supply chain efficiency enhancement to high-volume operations and fast-moving consumer industry.

Design for Scalability & Flexibility

Warehouse layout and design are essential in terms of scalability and flexibility, which are crucial to future growth. The warehouse layout plan is modular in order to make changes in volumes. This flexibility enhances inventory management and contributes to changing business requirements, cost reduction, and continuous enhancement of supply chain efficiency.

Factors Affecting Warehouse Design

Some of the factors that affect the process of warehouse layout design are the type of product, volume of storage, equipment and regulations. By matching them with warehouse space optimisation, the efficiency is guaranteed. Neglecting them can cost us productivity, inefficiencies and safety risks, but undoubtedly, it is crucial to take due pains to improve the competitiveness of supply chains by taking care of them.

Types of Goods

The nature of the goods defines the choice of warehouse storage systems and warehouse layout. Perishable goods demand a cold warehouse, and bulk goods demand dense shelving. The connection between layout and goods guarantees efficient flow of goods in the warehouse as well as facilitating improved handling, which has a direct influence on the impact of warehouse layout on productivity.

Volume of Goods

Volume is a factor that affects the optimisation of space in a warehouse. The high volumes demand small layouts with effective order-picking designs, and the low volumes demand flexibility. An appropriate analysis in this case guarantees a more efficient flow of operations within the warehouse and helps to implement the warehouse cost reduction strategies in different supply chain structures effectively.

Equipment & Technology

The design and layout of a warehouse are guided by equipment and technology. The sophisticated systems, such as conveyors or robotics, enhance the flow of operations in a warehouse, contribute to automating inventory management, and increase efficiency. The combination of these allows long-term scalability and helps to implement the strategy of cost reduction in the warehouse by minimising reliance on labour.

Safety Regulations

Safety regulations can influence the process of warehouse layout design. Compliance means secure employees, fewer accidents, and streamlined operations in warehouses. Regulation-friendly design is also valuable to supply chain efficiency improvement since safer environments eliminate expensive delays, interruptions, and liability, leading to sustainable growth in logistics.

FAQs

1. What is the role of warehouse operational flow?

The flow of the operations within the warehouse guarantees the efficient flow of goods through the warehouse, i.e., receiving to dispatch. It has direct impacts on productivity, accuracy and safety and helps to save costs and enhance logistics management efficiency.

2. How can layout design reduce logistics costs?

The process of designing an optimised warehouse layout reduces travel time, enhances accuracy in orders, and minimises handling errors. These efficiencies reduce labour and transportation costs, establishing effective strategies to reduce warehouse costs throughout operations.

3. How do warehouse storage systems affect layout design?

The storage systems at the warehouse establish the manner in which things are stored, retrieved and accessed. The ability to adequately integrate facilitates space management in the warehouse and better inventory management and also facilitates faster operation, which eventually fortifies the overall plan of warehouse layout.

4. How does warehouse layout impact supply chain efficiency?

An orderly warehouse design enhances the warehouse circulation, accelerates order picking and decreases bottlenecks. These advancements lead to the optimisation of supply chains, which allows companies to create quicker deliveries and savings.