Integrated Logistics:

Integrated logistics is the workflow where all the processes related to the materials’ delivery, order receiving, or risk management occur with the help of new technologies and data analysis. This ideal approach also promotes effective communication and documentation of the entire supply chain process hence cutting costs while at the same time increasing customers’ satisfaction. These fragments pertain to supply chain fluidity, minimization of costs, and customer orientation, which makes SCM critical for viable and competitive operations.

Why Integrated Logistics is Important for Business:

Integrated logistics is important in business organizations because integrated logistics makes it easy to plan, organize, source, control, and communicate business flows which results in a reduction of cost and improved quality of service delivery. Thus, the strategies for the integration of various logistics functions are as follows: The integration of various logistics functions ensures better and faster processes, limited delays, and fast adaptation to market changes. This in turn leads to improved customer satisfaction, company competitiveness, as well as better financial returns.

Difference Between Logistics and Integrated Logistics:

Logistics still merely considers individual activities such as transport or storage. On the other hand, integrated logistics meaningfully entail all these functions in a single entity. The key focus of integrated logistics is the coordination of operations along the supply chain, with maximum visibility and communication between the segments, and the managerial efforts to achieve enhanced, timely coordination with the help of technology compared to traditional logistics.

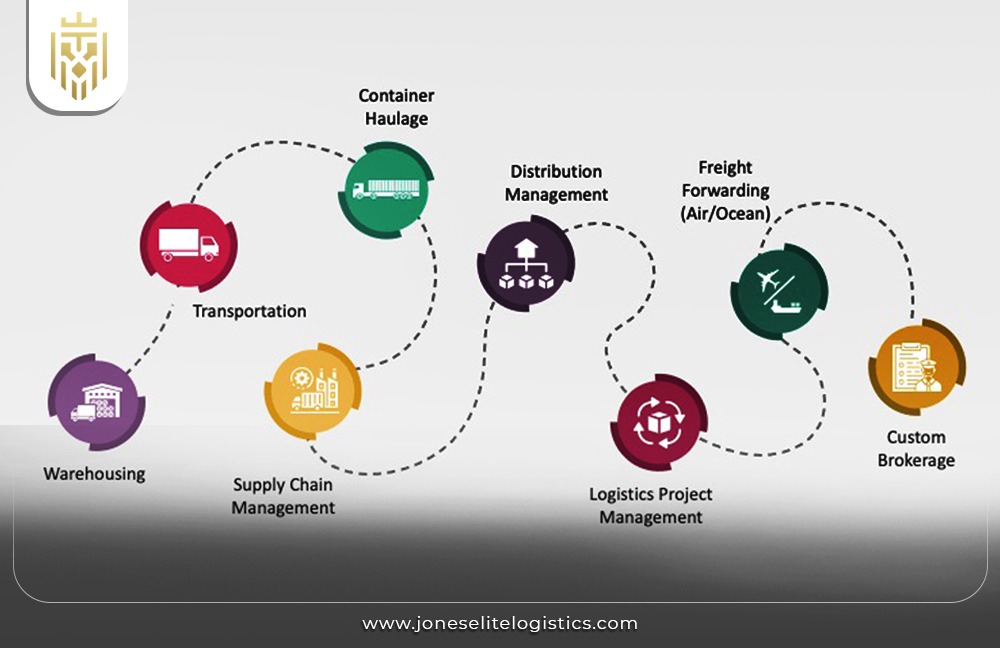

Components Of Integrated Logistics:

Managing the supply chain is made up of several fundamental parts that are essential in the planned integration of logistics. Some of the key supply chain management activities are in areas such as procurement, transport and distribution management; risk management; decision support; systems and technology integration; supply chain flexibility; cost containment; and customer focus. All of them are significant for achieving the goal of organizing the effective transit of goods and materials within the supply chain.

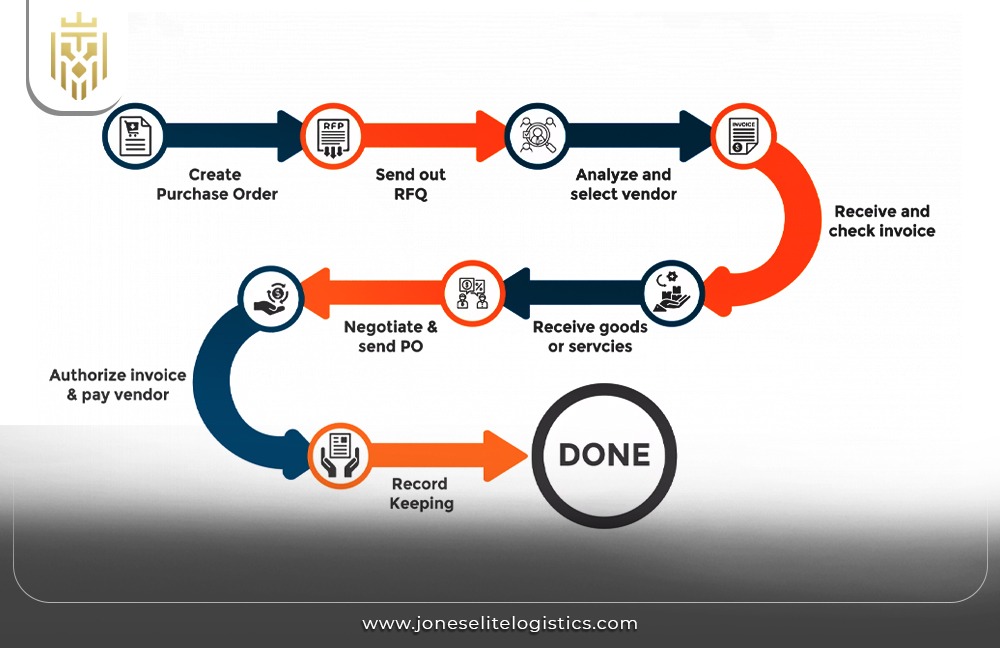

Procurement:

Integrated logistics procurement covers the activities of sourcing and acquiring all the consumer goods and services that are essential in the production process. It ensures that materials needed are bought at the greatest level of cost, quality, and time in order to support the overarching logistics strategy and avoid the dreaded stock out.

Shipping and Delivery Management

Shipping and delivery management is defined as the management of the physical movement or flow of goods from the suppliers to the customers. It involves optimization of the route to be traversed as well as a choice of carrier that will enable timely deliveries to customers, hence improving customer satisfaction while minimizing the costs of deliveries.

Risk Management:

Integrated logistics entails managing risk that is likely to cause disruption in the supply chain starting from risk identification and risk analysis. This also means safeguarding of such risks as unpredicted failure of suppliers, transportation problems, and changes in regulation among others to stabilize and protect its logistics.

Data-Driven Insights:

Analytics and big data are used to carry out an analytical assessment to come up with effective and informed decisions when it comes to logistics operations. Through a study of the functions of analytics, firms can anticipate demand for their products, manage stock, manage delivery channels, and supply chain, and consequently, create and execute effective supply chain management plans.

System and Technology Integration:

Integrated logistics and technology system concepts in integrated logistics imply implementing IT applications for the coordination of various logistics activities. This ranges from the implementation of ERP systems, TMS (Transportation Management Systems), communication technology, and other applications to ensure that there is effective communication in order to increase accountability, transparency, and efficiency in the chain of supply.

Supply Chain Agility:

The following element of logistics is defined as the capability of the supply chain network to respond to dynamics and shocks. This encompasses the ability to quickly adapt product manufacturing, supply, and delivery plans as dictated by the market trends or any other calamity that may arise with servicer and reliability.

Cost Efficiency:

The economic concern is the efficiency of the cost in the ambit of integrated logistics that strive to reduce the blows without diluting the quality. It entails cutting costs, minimizing unnecessary expenses, the possibility of convincing suppliers to provide cheaper goods and services, and automating procedures to enhance efficiency, thereby cutting expenses while making high revenues for organizations.

Customer Centric Approach:

The customer-oriented approach of integrated logistics means the provision of supply chain services that go the extra mile in fulfilling and even surpassing customer demands. This embraces consistency in deliveries, timely and flexible service delivery, and communication, all of which contribute to high customer satisfaction and hence the high customer loyalty that is necessary in any business that wants to expand its markets.

Examples Of Integrated Logistics :

In India, integrated logistics is demonstrated through the likes of Flipkart and Reliance Industries. Flipkart has an effective supply chain management program that uses technology for tracking and automated warehouses for delivery, and a strong network of suppliers and delivery agents to handle its large supply chain. Reliance Industries employs a system of logistics and this is by employing efficient integrated logistics whereby there is minimal warehousing but cross docking is employed, thereby eliminating long storage time from the point of delivery to the point of dispatch. The following are some of the methods implemented by these industries:

Green Logistics:

Environmental logistics or green logistics, deals with efforts made to reduce the effects of logistics on the environment. This covers factors such as adopting environmentally friendly means of transport, finding the shortest distance to travel to minimize fuel use, environmentally friendly ways of storing goods, and even packaging the products. As the term suggests green logistics ensures that efficient transportation throughout the supply chain does not have a negative impact on the environment.

Reverse Logistics:

Reverse logistics deals with the flow of goods from the end users to sellers or producers or the systems used to achieve this. This may involve product returns, recycling, and disposal or sweeping strategies. Reverse logistics can better enable manufacturers and retailers to restore the value of these returned products, enhance customer satisfaction, and promote environmental conservation in the management of waste.

Collaboration with Suppliers:

When it comes to integrated logistics relationships with suppliers, the partners need to be closely connected and cooperate with one another. This can involve such as exchanging sales and production forecasts, synchronizing delivery schedules, as well as integrating premier systems for sharing real-time information. Risk management, reduction of lead times, and maximization of efficiency are some of the benefits facilitated by supplier collaboration.

Efficient Warehouse management:

The integrated logistics technique of warehouse management requires the application of certain modern technologies such as automation, robotics, and inventory management systems. This helps to maximize space usage, avoid time wastage when searching for items, and keep a record of the available stock. In general, efficient warehousing saves cost since the flow of goods is optimized together with speed and accuracy when fulfilling orders.

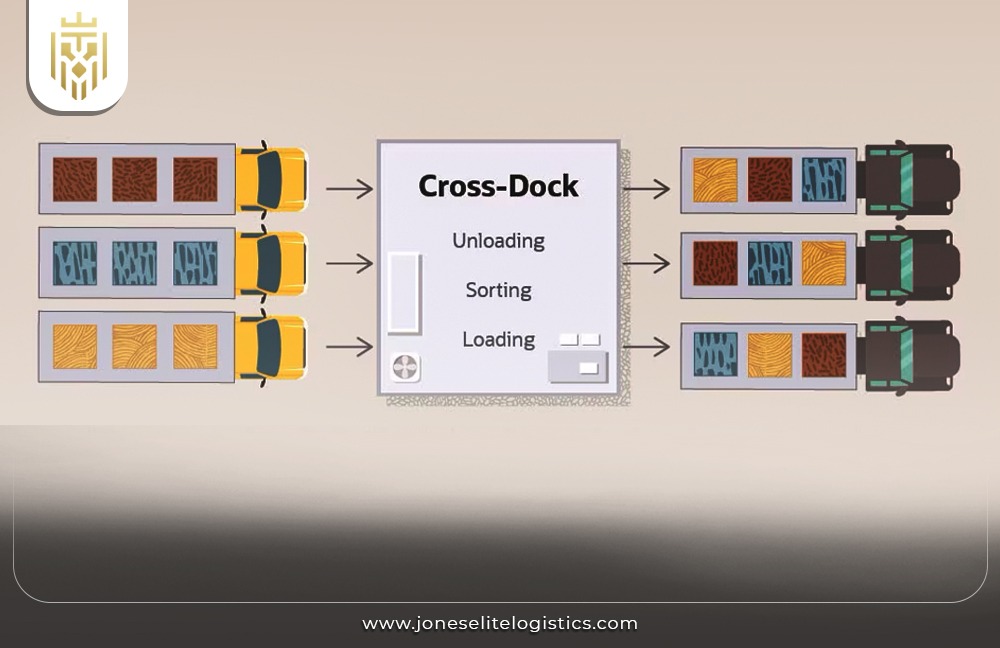

Cross Docking:

Cross docking as a method of handling logistics entails receiving products and forwarding them to their destination, with little or no warehousing time. This in turn has a positive effect on warehousing as it cuts down on its costs; it also has a direct impact on delivery as it accelerates it; and lastly, it significantly affects the turnover of inventory. Integrated logistics is a concept that has incorporated an important element called cross-docking to increase its effectiveness and flexibility in the supply chain.

Real Time Tracking Systems:

Auto tracking systems offer optimized information with real-time facilities in case of the location and condition of the products in a network. These systems thus employ the GPS among other techniques in order to track the shipments to enhance control. Real-time tracking enables business organizations to be certain that deliveries are on track and makes it possible for them to look for treatments promptly in case there are several distinct potential issues that may hinder customer satisfaction.

Benefits of Integrated Logistics:

Integrated logistics aims at providing value-added benefits such as integrated use of assets, customer value creation, evidence-based decision-making, process automation, and reduction of operational costs. Focusing on the role and purpose of logistics, the integration of all logistics functions takes a higher value of efficiency, flexibility, and cost reduction positively affecting the competitive advantage and operational performance of businesses.

Optimises Resource Management:

Transactional coordination enhances resource utilization in that it ensures that all resources in undertaking the logistics are well utilized. This involves ensuring that potential risks regarding sourcing, transportation, and storage are managed and controlled to optimize operational efficiency. If resources are well managed, then productivity is bound to improve, adding to it it shall also cut the cost.

Improves Customer Service:

Integrated logistics means that customer service also needs to be bettered and is done by offering deliveries on time and without errors and providing the buyers with real-time updates and fixes for any occurring problems. Accordingly, it is clear that making supply chain improvements can increase reliability and flexibility to meet the customers and therefore improve customer satisfaction.

Data-Driven Decision Making and Planning:

In integrated logistics, predictive and prescriptive planning and analytics are critical throughout the different stages of the value chain for demand, stocks, and route planning. This results in more accurate and strategic actions and minimization of various risks which makes this approach very effective in driving efficiencies.

Automated Process via Technology:

Integrated Barcoding Systems in integrated logistics are the use of robotics, automated sorting functions, and Artificial intelligence analytics. Automation eliminates chances of human interference and time consumption in factors like assembling and packaging, among others, thus increasing efficiency as well as decreasing operational costs.

Lowers Operating Costs:

Integrated logistics also serves the useful purpose of cutting costs by overhauling supply chain functions, minimizing inefficiencies, and managing resources more effectively. Practices such as cross-docking and efficient storage and transportation, tracking of products, and inventory all reduce costs that are inherent to storage and handling, increasing overall profitability.

FAQs

1) What is Integrated Logistics?

Integrated logistics applying technologically sophisticated concepts, tools, and insights concerning purchasing, transportation, and risk management as its major synthetic activity. Its role is to optimize business processes, minimize expenses, and improve customer satisfaction with the proper management of supply chain communication.

2) What are the benefits of integrated logistics?

The advantages of integrated logistics include the efficient and effective use of resources with minimal wastage, improving the quality of services to the end users, decisions made based on facts and figures, less manual work, and overall low operating expenses. Through the amalgamation of all the logistics functions, businesses are empowered with improved efficiency, efficacy, and costs to meet the market demands and standards hence improving the overall competitiveness and operations.

3) What are the Components of Integrated Logistics?

Subcategories of integrated logistics involve purchasing and receiving logistics, delivery and forwarding, risk analysis, information analysis, integration of system and technology infrastructure, supply chain response flexibility, low-cost structure, and customer focus. All those components play an important role in achieving an effective, efficient, and timely just in time process in the logistics system.

4) What is the importance of Integrated Logistics?

Integrated logistics remains important to businesses as it makes management easier and more efficient while at the same time increasing the quality and efficiency of service delivery. Applying different links of logistics, there is the possibility to achieve more efficient organizational processes, free from gaps and fluctuations which will allow to improve customer satisfaction, gain competitive advantage, and, as a result — increase companies’ revenues.