Ocado: The Robot Army That’s Redefining Grocery Delivery

Getting on with an automated warehouse system into the future, Ocado went beyond being a British online grocer and developed into a global tech company. Its robotics and logistics, powered by AI, advance efficiency standards in grocery delivery.

The Grocery Startup That Thought Like a Tech Giant

Established in 2000, Ocado was all about technologies from its very genesis, building from scratch systems that operate its own warehouses as well as those of several large retailers globally. This tech-centric attitude has built Ocado on the forefront of innovation in warehouse automation.

The Hive: Where Swarms of Robots Replace Supermarket Aisles

At the heart of Ocado’s operations lies “The Hive”, a revolutionary automated storage system in warehouses that reimagines traditional grocery fulfillment.

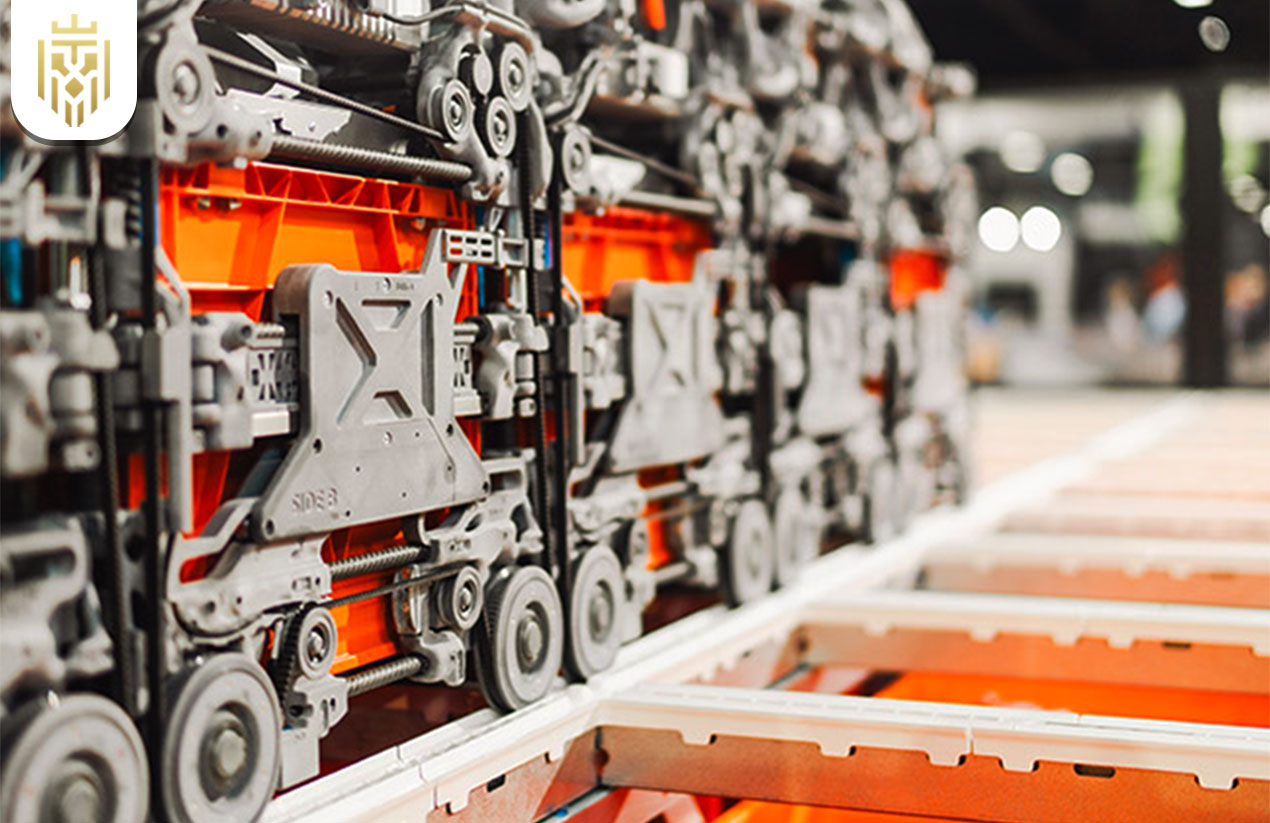

Inside the Hive: Anatomy of Ocado’s Automated Warehouses

The Ocado hive warehouses utilize a sophisticated grid system; thousands of robots work in unison to store inventory and fulfill orders in an extremely fast and accurate manner.

The Hive System

It consists of a three-dimensional grid where groceries are in chutes with storage bins up to 21 units high. The system is designed to maximize storage density and maximize speed in retrieval.

Robotic Operations

Ocado robots can move at a speed of 4 meters per second in the grid to pick and place items. An AI-based control method communicates to and from each robot up to ten times per second, managing their motions to avoid collisions and optimize efficiency.

Human-Robot Collaboration

Where the automation gets the bulk of the work done, human workers become important in packing and quality control, keeping every order to the highest specifications of Ocado.

A Platform That Powers Grocers Globally

Ocado’s technological setup extends beyond its own operations, comprising an entire platform that empowers grocers across the globe to use automation.

End-to-End Solution

This solution allows retailers to offer smooth and efficient grocery service with online shopfronts, warehouse automation, and logistics for last-mile delivery integrated in one single package.

Global Adoption

Some top retailers, such as Kroger in the U.S., Sobeys in Canada, and Coles in Australia, have been engaged by Ocado to put into action its automated warehouse solutions, thereby indicating the global reach and effectiveness of the technology.

Technological Components

Ocado’s platform combines robotic automation with AI-based order management systems and real-time data analytics to optimize the entire grocery fulfillment journey, from managing inventory to finding delivery routes.

Ocado’s Formula: Store-Free, Waste-Free, Ultra-Efficient

Ocado’s innovative approach eliminates the need for traditional shopfronts, reduces food waste, and enhances delivery efficiency through advanced technology.

How Does Ocado Nearly Eliminate Waste?

With perfect demand forecasting and just-in-time inventory management, Ocado reduces overstocking and spoilage, leaving food wastage much lower as compared to that of conventional grocery systems.

Smart Routing, Fast Groceries: Ocado’s Last-Mile Innovation

Ocado uses complex algorithms to plan its delivery routes to maximize timely and efficient deliveries. The system allows for same-day and next-day delivery options to keep up with the growing consumer demand for speedy grocery fulfillment.

FAQs

1) How is Ocado’s delivery faster or better than other grocery services?

Ocado’s automated systems rapidly process orders, with robot pickers that complete a 50-item order in five minutes on average, enabling faster and more reliable deliveries.

2) What role does automation play in Ocado’s last-mile success?

Automation supports high accuracy in fulfilling orders and optimizes delivery routes, reducing errors and delays in the last mile delivery process.

3) How does Ocado reduce food waste in deliveries?

Ocado’s advanced forecasting and inventory management very well align supply with demand, thereby reducing excess stock and waste that could lead to food spoilage.