An Introduction to Inventory Management

Inventory management involves managing inventory levels to meet customer demand and maintain low costs. A proper managing system leads to timely delivery, shortage prevention, and smooth alignment between supply and demand.

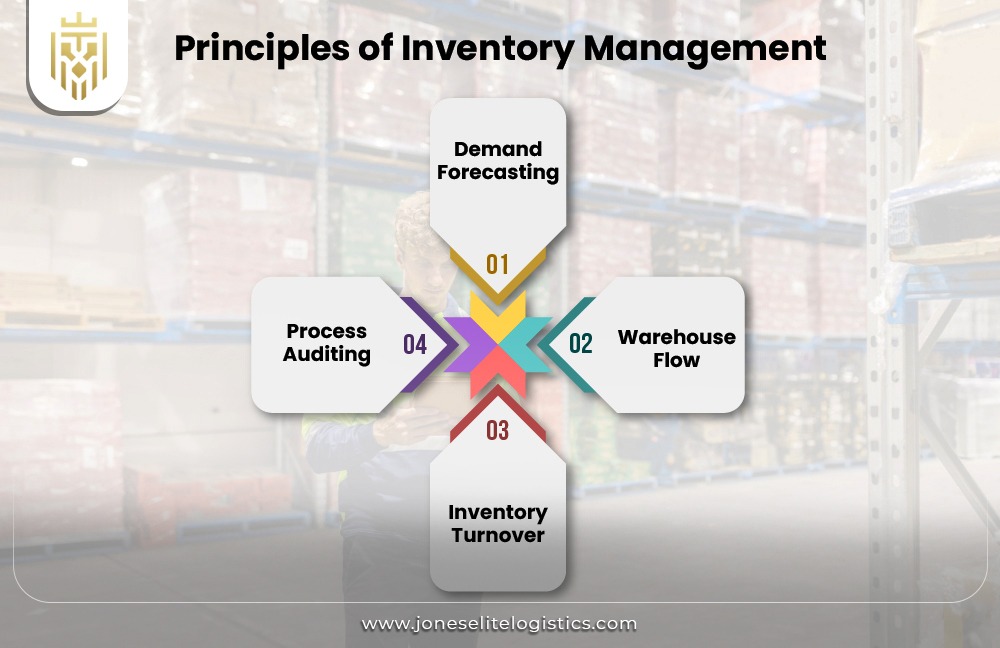

What are the Principles of Inventory Management?

To understand what are the objectives of inventory management, we must recognize how core principles – demand forecasting, warehouse flow, inventory turnover, and process auditing – help businesses achieve goals such as cost reduction, stock optimization, and improved efficiency.

-

Demand Forecasting

Demand forecasting is empowering the inventory management system in predicting future demand to avoid overstocking or shortages. This crucial function relates to what are the objectives of inventory management by aligning inventory with the actual market trends.

-

Warehouse Flow

Warehouse flow contributes to every inventory management set-up. Channelling stock movement-from receiving to shipping-aids in productivity objectives of such setting as lesser delays, better space usage and cost efficiency throughout the management system.

-

Inventory Turnover

Inventory management essentially checks turnover as the parameter for efficiency. High turnover of inventory signifies efficient use of such stock, which serves one of the key objectives of minimising waste and cost through faster-moving products and better shelf utilization.

-

Process Auditing

Auditing of forms in the inventory management system ensures compliance, effectiveness, and improvement. This upholds the objective of inventory management concerning transparency and pointing out bottlenecks in processes across the storage, demand, and supply stages.

Objectives of Inventory Management

The objectives of inventory management include consistent supply of materials, minimal wastage, balanced inventory management, efficient storage solutions, increased sales, and maintaining optimal stocks level. Every inventory management system must align its strategy with these key objectives for optimum performance.

-

Consistent Material Supply

A major objective of inventory management is that raw materials are kept at an even keel so that stockouts are avoided. The inventory management system guarantees constant movement of goods in and out to meet production and sales targets without disruptions and delays.

-

Minimum Waste:

One major objective of inventory management is to minimize waste. This includes lean practices that entail avoiding excess and maximising the usefulness of materials to minimize costs and environmental impact within the supply chain.

-

Balanced Inventory Management

Balanced inventory management involves avoiding both overstocking and shortage situations. This aligns with what are the objectives of inventory management and, therefore, acts to help businesses keep stock levels that lower costs, improve services, and avoid obsolescence.

-

Efficient Storage Solutions

Efficient storage goes with the objectives of inventory management, maximising space and minimising costs. An organized system of inventory management will allow faster picking, thereby reducing errors and optimising the warehouse infrastructure.

-

Boosting Product Sales

The enhancement of sales is an actionable goal of inventory management. A proper inventory management system guarantees ready availability of fast-moving items, thereby avoiding lost opportunities, and also helps in analysing slow movers for efficient inventory.

-

Maintain Optimal Stock Levels

Maintaining an optimum level of stock is one of the primary objectives in inventory management, balancing customer satisfaction and operational costs. Therefore, the inventory management system prevents unnecessary locking-up of capital while ensuring timely availability of products.

Features of Inventory Management

Core features of inventory management systems include advanced stock monitoring, asset and inventory tracking, data reporting and analytics, and cloud integration, which facilitate achieving the objectives of inventory management and improve efficiency and precision across the supply chain.

-

Stock Monitoring

Real-time stock monitoring is a crucial feature in inventory management systems that allows businesses to monitor the levels and locations of products. This promotes key objectives like waste reduction, informed decision-making, and reduction of stock discrepancies.

-

Asset and Inventory Tracking

Inventory management encompasses tracking the movement of assets and stock, rendering real-time information available. This thereby reinforces the objective of inventory management to optimize resource usage and enhance operational transparency.

-

Integration with Cloud-Based Technology

A cloud-based inventory management system supports decision-making using data, real-time tracking, and seamless scalability. These applications map onto the key objectives, rendering inventory control more accurate, collaborative, and accessible across departments.

-

Data Reporting and Analytics

Analytics incorporated in inventory management systems assist organizations in tracking stock movement, demand, and sales. Such reports support inventory management objectives such as cost control, demand planning, and improved stocking alternatives.

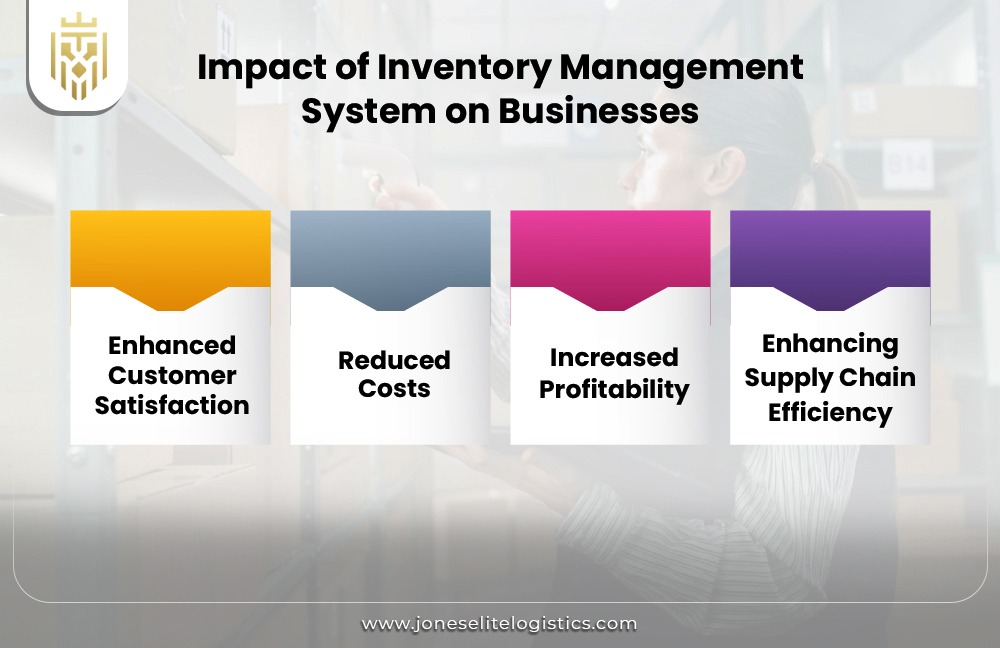

Impact of Inventory Management System on Businesses

Tight systems of the inventory management have their direct improvement upon enhancing the outcome of business and achievement of inventory management goals such as controlling costs, increasing customer satisfaction, and improving operational efficiency along the value chain.

-

Enhanced Customer Satisfaction

Good inventory management provides the product on time, with fewer delays. This ties to the objective of inventory management, which is to improve customer experience through accurate demand forecasting and minimising order disruptions.

-

Reduced Costs

They will save money by optimising stock levels and thereby lowering carrying costs. Reducing overhead in order to avoid losses caused by damage, spoilage, or overstocking is one of the main targets.

-

Increased Profitability

The profitability increases through improved inventory management efficiency and reduced costs. In support to the overall inventory management objective, those systems reduce wastage at stock handling and support sales with accurate availability.

-

Enhancing Supply Chain Efficiency

The Inventory management systems synchronise stock levels to demand, thus streamlining the supply chains. A key objective is avoiding overstock and stockouts, thus enhancing flow and reducing shipping delay and time responsiveness.

FAQs

1)What are the 6 objectives of inventory management?

The objectives of inventory management include consistent supply of materials, minimal wastage, balanced inventory management, efficient storage solutions, increased sales, and maintaining optimal stocks level.

2) What are the Features of Inventory Management?

Core features of inventory management systems include advanced stock monitoring, asset and inventory tracking, data reporting and analytics, and cloud integration, which facilitate achieving the objectives of inventory management and improve efficiency and precision across the supply chain.

3) What are the challenges of Inventory Management?

Challenges of inventory management include wrong demand forecasting, stockouts or overstocking, high holding costs, inefficient inventory management systems, lack of real-time data, and poor organization in their warehouses, thereby making it difficult to achieve their main objectives.

4) What are the principles of Inventory Management?

The core principles of inventory management are demand forecasting, warehouse flow, inventory turnover, and process auditing.