Inventory management involves keeping the right balance of stocks of products to be prepared to meet the needs of the market without having to stock more than what the market would require or less than what is required. It improves cash reconciliation, decreases storage costs, mitigates risks inherent in inventory, and raises organizational productivity.

Difference between Small Scale and Large Scale Inventory:

Micro inventory management usually pertains to the handling of lean inventories, straightforward storage peculiarities, and even often a basic recording process. The major differences between large-scale and typical inventory management regimes include large volumes, intricate storage solutions, integrated technologies, and comprehensive analytics. The scale influences some of the inventory management system characteristics such as the levels of complexity, cost, and applied technology.

Types of Inventory Management:

The inventory management types include perpetual inventory, periodic inventory, ABC analysis, just-in-time (JIT), consignment, first-in-first-out (FIFO), and Last in First out (LIFO). Every type is applied for different business requirements for tracking products more frequently or less often.

Perpetual Inventory Management:

Real-time inventory means inventory records are updated as sales or purchases are made a type of inventory system called perpetual inventory. This method involves the use of gadgets like bar code scanners and computer-aided inventory control systems and this enables one to get accurate and up-to-date stock information that aids in real-time decision.

Periodic Inventory Management:

Periodic inventory involves taking inventory of the goods in stock at periodic intervals; for instance, every month or every year. In the process, they perform physical counts on inventories to check on the physical stock. Although they are less expensive than perpetual systems, they can add inaccuracies and slow updating that may culminate in stockouts or excess stock between counts.

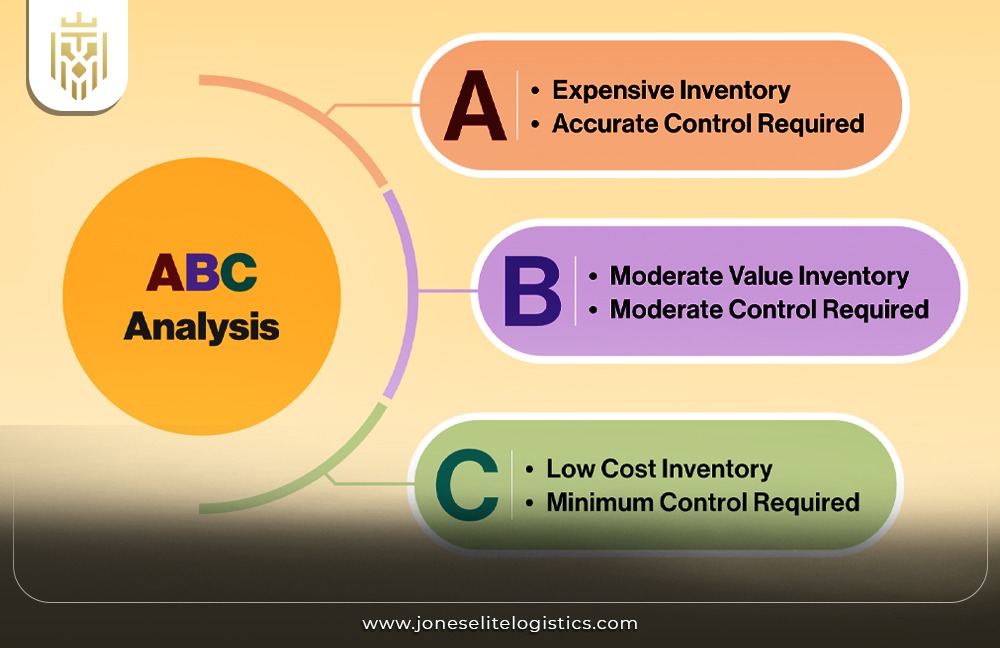

ABC Inventory Management:

ABC inventory management categorizes inventory into three classes based on value and importance: Vendors have been categorized in three: A (high value, low volume), B (moderate value, moderate volume), and C (low value, high volume). Through this method, the available resources and managerial time are directed toward the most relevant items to optimize inventory uses and hence minimize holding costs.

Just-In-Time Inventory Management:

The JIT inventory technique is targeted at stock reduction by ordering products when they are required for production or consumption. This approach lowers holding costs and stock that is later deemed unnecessary but demands accurate demand prediction and robust supplier relationships to avoid stock shortages and delays.

Consignment Inventory Management:

Consignment stock management refers to a system where suppliers deliver their products to the buyer, and the buyer is responsible for selling the products, but the actual ownership of the products remains with the supplier until the products are sold. This method lowers the buyer’s capital investment and inventory risk and the supplier gains visibility and demonstrative sales even though the buyer buys without bearing immediate cost.

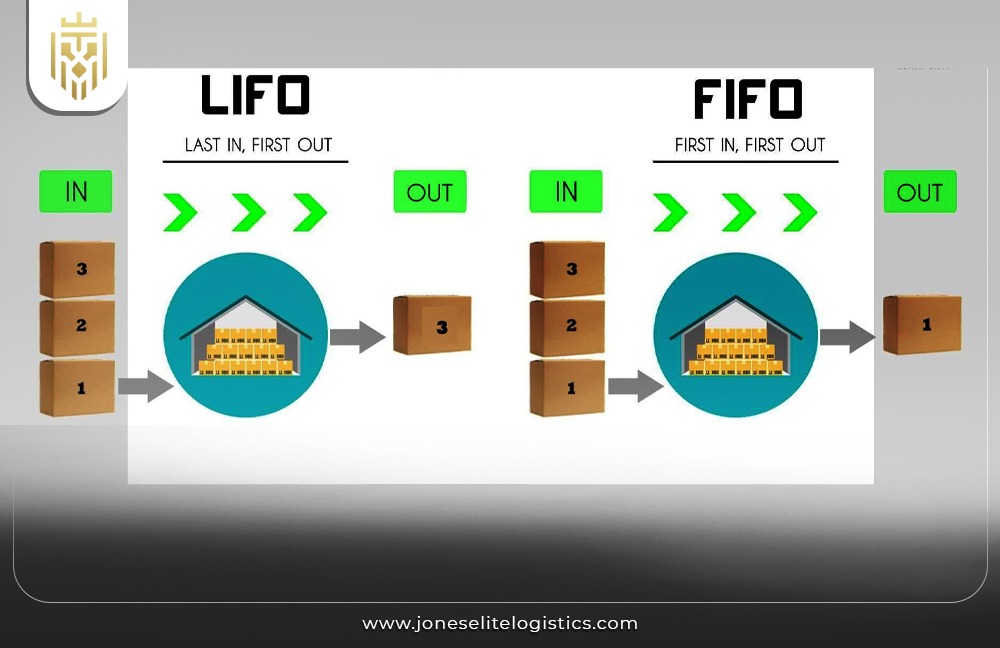

FIFO and LIFO:

FIFO (First-In-First-Out) maintains the business proposition that the first items in the inventory have been bought first and sold first with minimal probability of becoming obsolete. LIFO on the other hand implies that the actual amounts that were the most recently purchased are sold first, and this may reduce the taxable income during inflation but harm inventory accuracy as may leave old stock unsold.

Benefits Of Inventory Management:

Managing inventories can bring several advantages: proper inventory levels, inventory shrinkage, storage cost, warehouse operations, and brand development. It enables organizations to satisfy the demand of customers without having to make unnecessary orders that may lead to purchasing products that are not moving well, thus cutting costs and enhancing cash flow.

Optimize Inventory Levels:

Inventory management aims at approving suitable stock to meet demand without buying excess lots or inadequate amounts for a business. This curb of costs helps to lower the cost of carrying stock, reduces the propensity of stock being rendered obsolete, and enhances the cash flow thereby enabling the organization to run more efficiently and deal with changes in the market fashion.

Minimize Losses:

The very important function of inventory management is to minimize the losses due to theft, damage, or even the inventories becoming obsolete. For this reason, business management should incorporate efficient record keeping and installation of tracking systems to easily detect any variations, minimize losses, and properly handle inventory to safeguard their investments.

Reduce Storage Costs:

Managing storage requirements entails setting proper inventory control measures that would prevent excess stock which will need more storage space besides other resources. Effective inventory management allows for limited warehousing, thereby cutting on the cost of utilities and insurance as well as getting rid of any stock that may lead to loss, which is beneficial for the business as it leads to low costs.

Enhance Warehouse Operations:

Optimized warehouse operations arise from effective management of stock, either through proper positioning of stock, actual order picking, or proper exploitation of technology. Optimizations help minimize picking and shipping mistakes, enhance methods’ effectiveness, and guarantee any inventory is easily retrievable, which contributes to operations’ effectiveness.

Foster Brand Loyalty:

Brand maintenance, on the other hand, entails, making sure that there is timely and accurate restocking of products so that a firm can continuously make deliveries to its customers. In the context of customer needs and avoiding stockouts, customer satisfaction is increased, trust is gained, and they are likely to use the brand more in the future, making the firm more profitable.

Challenges Of Inventory Management:

The challenges that inventory management experiences include data identification of stock details, ineffective processes, fluctuations in customer demand, and space utilization in the warehouse. Meeting these challenges calls for good systems, ongoing amelioration and fine-tuning, and flexibility, thus being able to deliver sound and satisfactory operations.

Getting Accurate Stock Details:

The issues such as poor record keeping, human errors, and theft pose significant problems in procuring actual stock details. Huge investment in organizations is made to ensure that accurate and real-time data is produced hence the need for effective inventory management methods such as installation of efficient inventory management systems, periodic auditing, and well-trained employees on inventory management.

Poor Processes:

Generally, a company tends to experience problems such as inefficiency, mistakes, and high costs when managing the stock. These problems can be solved through the improvement of operations by having standard working processes, implementing best practices, and adopting information technology to enhance inventory records, timely order deliveries, and minimizing operating costs.

Changing Customer Demand:

Fluctuations in customer demand should always be considered in business environments so that they can be effectively managed. It is necessary to accurately predict future demand for a specific item and use the appropriate flexibility to promptly make adjustments when stock conditions are frozen and cannot meet the customer’s needs or exceed them and cause a problem with excess stock.

Using Warehouse Space Well:

Proper utilization of the space that is provided by the warehouse is important so as not to cause congestion and to optimize the resources that are available at the warehouse. This is attained through systematic or planned locations of the stock, repositioning of stock, and adoption of methods of handling stock through tracking methods that utilize space effectively and efficiently.

Warehouse Inventory Management:

Warehouse inventory means the control, processing, location, or movement of the stocks within the context of a warehouse. This covers stock placement, space control, pick, pack, and ship flow design. Organized warehouse inventory control decreases four particular aspects: errors that are likely to occur, the time required to fulfill orders, inaccuracies in stock, and expenses toward storing and managing the inventory.

E-commerce Inventory Management:

E-commerce inventory management deals with the stock supply of goods for online retail businesses. It includes keeping track of inventory, the selling of products through various outlets, good handling of returns, and quick processing and completion of orders. E-strategies for inventory management are important to ensure that companies meet customer demands while avoiding situations that lead to stockouts or overstocks that could compromise the company’s competitive edge.

Inventory Management Trends:

Contemporary approaches to the management of inventory accentuate the utilization of modern technology tools in inventory management for effectiveness, reliability, and expandability. The major trends are tied to the employment of artificial intelligence, cloud solutions, and automated guided vehicles which increase effective performance that allows for monitoring processes’ real-time outcomes, cuts manual work, and leads to more effective decision-making and cost-cutting.

Artificial Intelligence:

AI for inventory control applies algorithms and data analysis techniques in recommending appropriate stock levels and making decisions without the intervention of a human being on the job. Employing AI saves time in prediction as well as pattern recognition and coming up with recommendations on inventory management hence leading to minimal costs and customer satisfaction.

Cloud Based Solutions:

Implementation of inventory management solutions on the cloud is advantageous owing to the flexibility it provides as well as the relatively low costs involved. They offer direct stock details updates, allow for effective system integration, and offer remote control. These solutions facilitate communication; provide accurate information; and address tasks, which allow companies to keep sufficient inventory stocks and operational efficiency.

Automated Guided Vehicles:

AGVs contribution to inventory management in a warehouse is that will help enhance the flow of goods in the warehouse through automation. They shave off labor costs, minimize errors with stock movement, and are more safe and efficient. They conform to the implementation of just-in-time inventory management and allow for space optimization thus enhancing warehousing functionality.

FAQs

1) What is the importance of inventory management?

Inventory management is a critical aspect of operation since it determines how much inventory a business needs to stock to meet the needs of its clients while at the same time minimizing the costs of having excess or insufficient inventory. This enables control of cash holding costs, minimizes holding costs incurred from products that take a long time before they are sold, reduces the chances of products going to waste, and increases efficiency.

2) What are the benefits of inventory management?

Other advantages of inventory management include the following: improved stock positions, reversed losses, decreased costs of storage, improved warehouse operations, and improved customer loyalty. It may lead to an increase in the efficiency of resources, timely collection of cash, and accurate predictions. Also, it enhances customer fulfillment by ensuring that products are in stock hence shortening the lead time.

3) What are the types of inventory management?

There are various methods of inventory management and they are perpetual, periodic, ABC, JIT, consignment, FIFO, and LIFO. Both types meet distinct business needs: RTV,project-based, value-oriented, periodic, and value-oriented with inventory optimization for minimum stock levels, SMV, and cost control.

4) What are the challenges of inventory management?

Some of the complexities of inventory management are, getting accurate OS, sub-standard processes, fluctuating customer trends, and effective space. These issues can only be addressed by having well-established systems that are constantly improving as well as flexible. Thus, inventory control acts as a crucial tool for maximizing operations, minimizing costs, and satisfying customers.

5) What is warehouse inventory management?

Warehouse stock management refers to the process of managing inventories in a location, specifically a warehouse for efficient handling. It comprises stock positioning, storage area control, and perfect order picking, packing, and dispatching systems. Optimization in warehouse inventory enables the reduction of mistakes, increases the rate of order picking, and increases the accuracy of inventories.