What is Warehouse Consolidation?

Warehouse consolidation involves bringing together small shipments from different sources and turning them into one bigger and more efficient shipment. The process takes place in a single location, known as a consolidated warehouse which brings all orders together and sorts them. Combining warehouses can lead to smarter logistics, less spending on shipping and more effective management of stock.

Who Uses a Consolidation Warehouse?

Most retailers, e-commerce companies, manufacturers and wholesalers use a consolidated warehouse for handling LTL shipments from several vendors. Placing smaller shipments together into one transport helps companies save money and organize their inventories if their sales fluctuate from month to month.

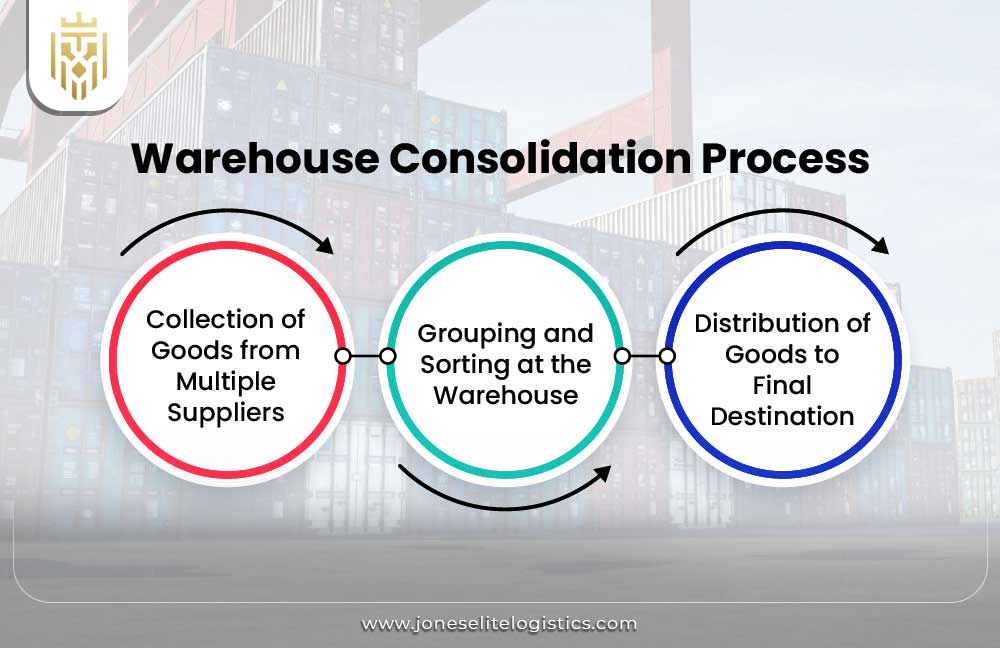

How does the Warehouse Consolidation work?

Warehouse consolidation starts by bringing goods from different sources, gathering them according to the destinations and delivering them from the central warehouse. It helps lower transportation charges and boosts the effectiveness of handling the company’s inventory.

Collection of Goods from Multiple Suppliers

A range of suppliers sends their goods to the consolidated warehouse. Each member of the team reviews material, cases things into different areas and contributes to the process of merging different shipments. During this step, key elements are combined which helps ensure better grouping and dispatch operations.

Grouping and Sorting at the Warehouse

In consolidation, shipments are assembled based on their destination, the type, or what the customer needs. It makes managing stock more efficient and lets you make use of the space available in your warehouse. Using one warehouse makes deliveries more efficient, leaves less space,e and helps oversee stock, which helps with delivery monitoring and lowers the cost of moving goods.

Distribution of Goods to Final Destination

When the goods are grouped, they are packed and given labels. The paperwork lists the unit loads in the overall shipment. Most of the time, loading is done automatically. Thanks to warehouse consolidation, companies can deliver goods quickly, save on transport, and manage their stock at one central place.

Importance of the Consolidation Warehouse

When small orders are arranged in a combined warehouse, it becomes easier to ship them at lower expense, handle stock and ensure the whole supply chain functions well. Understanding consolidated warehouses allows companies to cut their expenditure and achieve better logistics.

Reduced Transportation Costs

By handling many products in one shipment at a consolidated warehouse, businesses cut their transport fees. It cuts the cost of shipment per package, lowers the trips needed and makes trucks work at full capacity. Warehouse consolidation allows companies to buy more for less and send out shipments more frequently with less leftover material.

Cost of Goods Sold

When warehouses combine resources, businesses lower their costs of transportation and improve the way goods move through their chain. As a result, managing inventory gets easier and distribution is made simpler which lowers your COGS. As a result, companies enjoy more profits and operate with fewer expenses under better control.

Inventory Turnover Ratio

By consolidating inventory, a warehouse makes the inventory turnover ratio better. As stock is brought together, it keeps moving, thus improving the availability of cash and decreasing the time needed for storing products. As a result, businesses can handle their stock better and lower the possibility of products becoming outdated.

Inventory Age

A central warehouse makes it possible to get products to customers more quickly and reduces how long items remain unsold. As a result of combining warehouses, there is quicker product movement, improved product forecasting and fewer products that do not get sold. When you control inventory well and have fewer delays, freshness increases and you pay less to store products.

What is a Consolidation and Break Bulk Warehouse?

In a consolidated warehouse, several minor shipments are assembled into more effective truckloads. This lowers the costs of moving goods and makes logistics easier. However, a break-bulk warehouse separates big incoming loads into smaller consignments for delivery. The approaches are both useful for inventory management, but they focus on different parts of the supply chain.

Types of Warehouse Consolidation

The types of warehouse consolidation are inbound consolidation, outbound consolidation, cross docking and merge in transit. Every kind of warehouse supports its own way of consolidating goods, thus reducing expenses for shipping, speeding up deliveries and handling inventory in one area.

Inbound Consolidation

Inbound warehouse consolidation has shipments from different suppliers put and processed together in one warehouse. This method can lower the costs of getting goods delivered and ensures goods are delivered on time. In retail and manufacturing, it is important because keeping stock and providing items when needed is vital for the business.

Outbound Consolidation

Outbound consolidation takes small parcels and puts them into larger packages. It reduces expenses for transportation by preventing the use of too many almost-empty shipments. It also makes managing stock easier, mainly if delivery is taking place in the same region or service zone as the retail store or customer.

Cross Docking

Goods go straight from inbound to outbound transport using the cross-docking process. It comprises two parts – pre-distribution where destinations are known in advance and goods are pre-assigned, and post-distribution where goods are sorted after arrival based on real-time demand. Unlike the usual practice, it brings down the amount of inventory held. As it is part of warehousing consolidation, performing cross-docking can help accelerate the supply chain.

Merge in Transit

While products are brought together at a warehouse through consolidation, merge-in-transit does not need a warehouse at all. It is about forming a single group of goods from various shippers on their way to the same destination. Both warehouse consolidation and merge-in-transit bring about similar goals, even though their methods of consolidation are not the same.

Benefits of Warehouse Consolidation

The main advantages of using consolidation warehouses are saving money on transport, better tracking of items, minimal effort needed for unloading/loading and a decreased number of warehouses. Having an understanding of warehouse consolidation lets businesses become more efficient and decrease costs in the supply chain.

Smarter Inventory Management

Warehouse consolidation makes it easier to oversee inventory because it is stored in only one place. So, the brand is easier to find, extra stock is avoided and there is less chance of printing the wrong order. Consolidating warehouses makes it possible to shorten lead times, lower labour expenses and better manage flow and usage of space.

Reduced Transportation Cost

Combining various products into a single load is possible, which helps you save money on shipping and delivers more goods together. Because of this, companies spend less on transportation and need to send fewer messages. A well-planned consolidation strategy in warehousing gives businesses the benefits of strong service and low logistics costs.

Reduced Material Handling

When warehouses are combined, moving and checking products by hand is done less frequently. Fewer contact points along the chain lowers the chance of error which helps maintain good quality of goods and lowers costs for workers. The process of consolidation which streamlines everything, allows products to be moved straight from receiving to shipping.

Reduced Warehousing

The meaning of warehouse consolidation involves bringing warehouses together so their work is done from central locations. It cuts back on the expenses of rent, employees and utilities. This process plays a role in green logistics by optimising space, lessening waste and making the distribution of goods more efficient.

FAQs

1) What is Warehouse Consolidation?

Warehouse consolidation involves bringing together small shipments from different sources and turning them into one bigger and more efficient shipment. The process takes place in a single location, known as a consolidated warehouse which brings all orders together and sorts them.

2) What are the economic benefits of warehousing consolidation?

The main advantages of using consolidation warehouses are saving money on transport, better tracking of items, minimal effort needed for unloading/loading and a decreased number of warehouses. Having an understanding of warehouse consolidation lets businesses become more efficient and decrease costs in the supply chain.

3) What are the types of warehouse consolidation?

The types of warehouse consolidation are inbound consolidation, outbound consolidation, cross docking and merge in transit.

4) How does the Warehouse Consolidation work?

Warehouse consolidation starts by bringing goods from different sources, gathering them according to the destinations and delivering them from the central warehouse. It helps lower transportation charges and boosts the effectiveness of handling the company’s inventory.