What is product Inventory?

Product inventory includes all the raw materials, semi-finished, and finished goods that a business holds for production or sale. It ensures smooth operation, on-time deliveries, and cost control within the supply chains.

What a Product Inventory Management can do for your online inventory management?

Inventory management helps online businesses track stock in real-time, minimize errors, and fulfill orders from multiple locations, especially in India’s burgeoning logistics and e-commerce sectors.

How does Product Inventory work?

The following points explain the roles it plays in driving business efficiency and operational accuracy.

Customer satisfaction

An inventory that ensures products wanted by customers are available and ready for delivery reduces delays and sustains brand value. The late delivery and stockouts spoil trust and could drive customers away to competitors.

Supply chain efficiency

A well-kept inventory allows smooth cooperation among procurement, warehousing, and delivery teams. This shortens lead times; thereby, allowing just-in-time ordering, and avoids situations where they overstock or place orders for stocks.

Cost control

The management of inventory helps in reducing wastage, damages to stored goods, and unwanted purchases. In India’s SME setting, where budgets can be tight, controlling costs through inventory planning can be a big help to profitability.

Features of Product Inventory Management

The points below highlight some of the most effective tools used in today’s inventory management.

Automated Reordering and Alerts

This feature allows businesses to set stock threshold levels and receive an alert should the stock decrease below the specified quantities. This way, it can avoid overstocking from one side or unfortunately losing sale due to lack of stock-being-out-of- stock.

Multi-Location Management

Such businesses maintain multiple warehouses or have regional office locations and can transfer inventory management across locations from a centralized system. It is handy for a logistics provider operating pan-India.

Real-time Tracking and Monitoring

Stock movement tracking and monitoring with real-time status enable fast decision-making and reactive measures upon delays or occurrences.

Centralized Inventory Management

By aggregating all departmental and channel sales data, companies can have a single point of truth for inventory suggesting fewer discrepancies and better report accuracy.

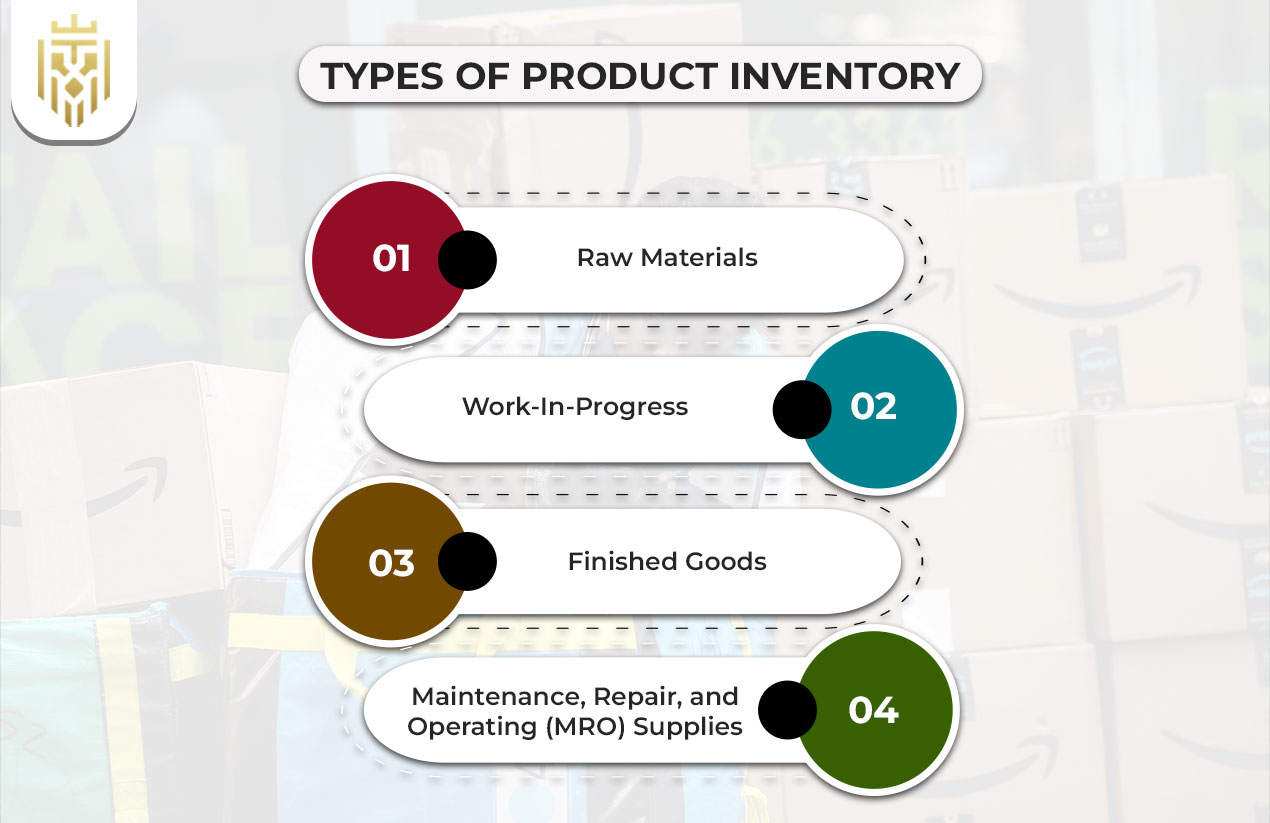

Types of Product Inventory

Understanding the types of product inventory helps businesses assign the right resources, timelines, and tracking methods for each category.

Raw Materials

Unprocessed inputs used in the production of finished goods. In FMCG or apparel manufacturing sectors, they would cover items like fabric, chemicals, packaging materials, or metal parts.

Work-In-Progress

These are semi-finished products being assembled or manufactured. WIP inventory is tracked to steer a company clear of production time delay and bottlenecks.

Finished Goods

These are products that have completed manufacturing and are ready for sale or dispatch. Finished product inventory should be monitored carefully to satisfy market demand and avoid piling up.

Maintenance, Repair, and Operating (MRO) Supplies

These are materials not part of the product but are necessary for continual operation. The MRO inventory includes safety kits, cleaning items, and spare tools.

Key Metrics to Track for Product Inventory

Tracking the right performance indicators ensures efficient stock handling, identifies improvement areas, and supports business scalability.

Inventory Turnover

Inventory turnover shows how many times inventory is sold and replenished during a certain period. Generally, if the turnover rate is fast, then sales are strong, and inventory control is deemed effective.

Days Sales of Inventory (DSI)

Days Sales of Inventory comprise the average number of days required to dispense current inventory. DSI being low means stocks move faster, and it is practically associated with a positive cash flow.

Order Accuracy Rate

This metric stands for the amount of orders that are fulfilled without error. The higher the rate, the lower the returns, and generally lower the dissatisfaction by customers. Also, the operational costs of such orders are less.

Stockout Rate

This metric represents the unavailability of an item at the time ordered. Frequent stockouts imply bad planning, with consequent losses in revenue and unsatisfied customers.

Challenges of Product Inventory

Despite the importance of inventory management, businesses often face challenges that disrupt workflow and increase costs.

Balancing Overstocking and Understocking

Maintaining inventory level is a never-ending challenge. While excess inventory drains capital and incurs storage costs, very low inventory results in missed sales opportunities and customer dissatisfaction.

Inefficient Warehouse Operations

Lack of organisation in storage setups and absence of automation measure slow order processing and a high rate of errors. This is often an issue faced by the old warehouses not yet updated with technology.

Manual Documentation and Processes

Reliance on spreadsheets or handwritten records will only lead to miscounts, data entry errors, and delays. Going digitised will assist with consistency and scalability for growing businesses.

FAQs

1.What is product Inventory?

Product inventory refers to the stock of raw materials, semi-finished, and finished goods a business holds for manufacturing, distribution, or sale. It’s a key part of supply chain and logistics planning.

2.What are the Types of Product Inventory?

There are four main types: raw materials, work-in-progress, finished goods, and MRO supplies. Each plays a different role in the production and sales process.

3.What is Indirect Procurement?

Indirect procurement involves purchasing goods and services that support business operations but are not part of the final product. These include office supplies, equipment maintenance, and IT services.

4.What are the Challenges with Indirect Improvement?

Challenges include lack of transparency, difficulty tracking spending, and inconsistent supplier management. These issues can lead to higher costs and operational delays.