What is Order Processing?

Order Processing is all about handling customer orders from order placement to final delivery, ensuring accuracy and efficiency. Automated systems can be used in order fulfilment, which is a critical aspect of order fulfilment, to improve customer experience. Implementing an automated order processing system ensures seamless order fulfilment and reduces processing time while maintaining order accuracy.

Why is Order Processing Important?

A robust order processing system improves customer experience, enhances brand reputation, and ensures efficient inventory management. It helps businesses track order status, manage inventory levels, and streamline sales order processing. Efficient order fulfilment fosters customer loyalty and drives repeat business, making order management a critical component of operations.

How Long does Order Processing take?

The duration of order processing depends on order details, product complexity, and shipping logistics. The standard order fulfilment process takes 1-2 days for simple products, while customized or high-value items may take longer. A well-integrated order management process minimises delays and optimises efficiency.

Types of Order Processing Systems

Order processing systems are categorised into traditional processing systems and modern processing systems. Businesses choose between these systems based on operational needs, scalability, and integration with their supply chain and order fulfilment strategies.

-

Traditional Processing Systems

Traditional order processing systems rely on manual documentation, increasing errors and processing time. They require extensive human effort for order entry, order confirmation, and purchase order management, leading to inefficiencies in inventory management.

-

Modern Order Processing Systems

Modern order processing systems use automation and order processing software to streamline sales order handling. These systems integrate inventory management system, order management software, and artificial intelligence to enhance accuracy and efficiency. Businesses benefit from real-time order tracking and reduced manual process inefficiencies.

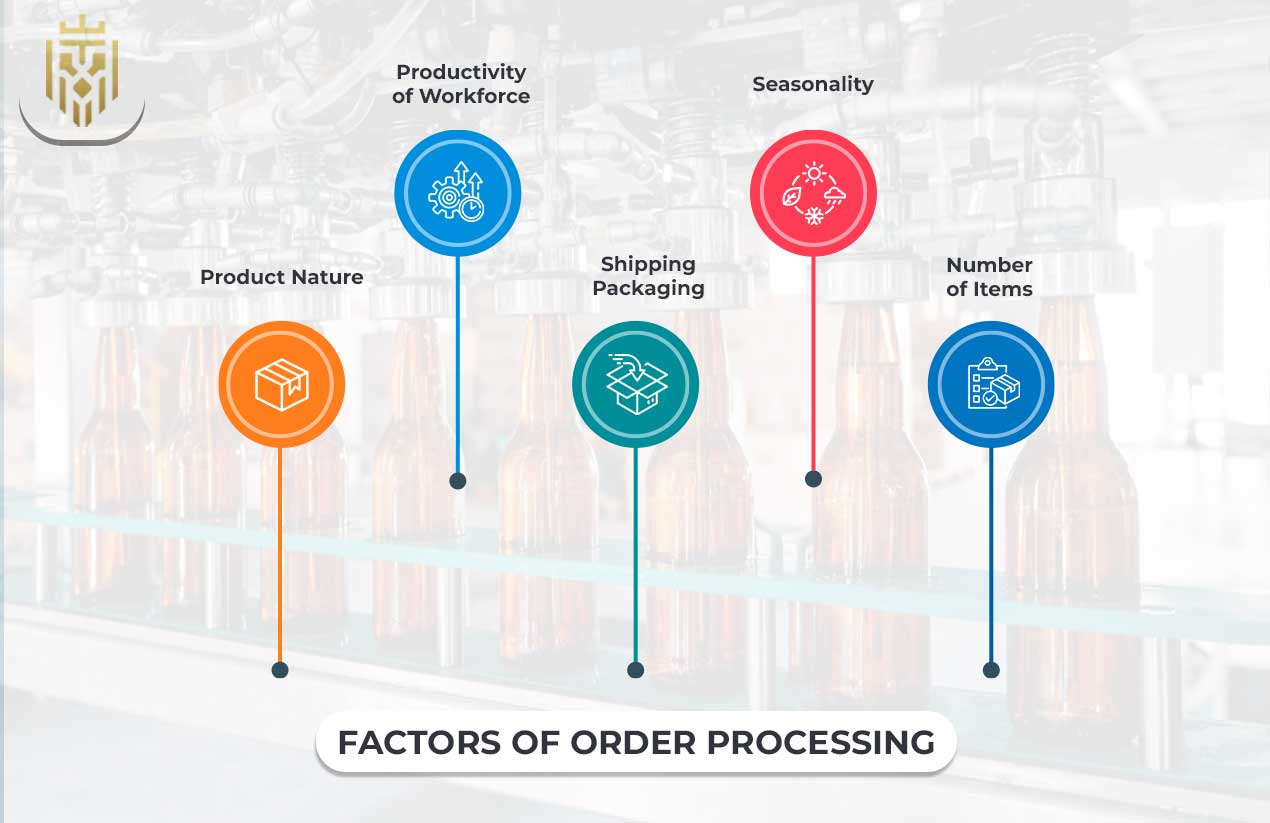

Order Processing Factors

Order processing factors include product nature, workforce productivity, seasonality, order size and packaging logistics. These elements affect processing efficiency, timelines, and customer satisfaction and cost and resource allocation in order fulfilment operations.

-

Nature of The Product

Order processing steps are determined by the product’s characteristics such as fragility, size, or perishability. Fragile goods must be specially handled and perishable products need faster order fulfilment process. For the safe transportation of high value items, secure dispatch logistics may be used.

-

Productivity of Workforce

Order processing efficiency is related to workforce productivity. A good balance of team members will help you perform operations smoothly and ensure timely order fulfilment. In manufacturing logistics, collaboration across departments improves order management efficiency.

-

Shipping Packaging

Packaging logistics has the capability to safeguard items while they transit and minimize costs. A key factor to consider is choosing the right materials, ensuring dimensional weight and accurate labelling to enhance order tracking, with optimised packaging logistics controlling costs.

-

Seasonality

Knowing seasonality enables business to match inventory management, staffing and other resources to demand changes. This way, companies predict seasonal peaks, and optimize the order processing and cut costs. Being proactive about your planning means you can get through high demand periods without any hiccups in your order fulfilment.

-

Number of Items

Order processing takes more time and resources if there are multiple items in the order. Delays are minimised by efficient planning, costs are controlled by optimised packaging logistics. The ability to balance labour and materials makes large or complex orders smooth. Optimized batch picking and warehouse coordination streamline order fulfilment.

Steps for Order Processing

Order processing comprises receiving orders, sourcing products, picking inventory, packaging, shipping and tracking. Accuracy, reliability, and efficiency are crucial in every order processing step to ensure successful order fulfilment and customer satisfaction.

-

Order Receiving

Customers order online or through a phone, and the order processing cycle gets started. Accurate and timely order fulfilment is forwarded to fulfilment centres to guarantee smooth dispatch and delivery. This step establishes a base for customer satisfaction.

-

Sourcing

Sourcing identifies suppliers that are financially sound (and not too dependent on a single customer) and that can meet price, delivery and minimum order criteria for efficient order processing. Purchasing the right vendor helps in smooth manufacturing logistics and good order fulfilment processes. Building long term supplier relationships requires proper evaluation.

-

Picking Inventory

Locating, sorting, and preparing items for order fulfilment needs are part of picking. This proper order processing ensures that inventory is picked and labelled efficiently. This also makes for smooth packaging logistics that accelerates dispatch and delivery.

-

Shipping

Transportation of orders is called shipping, which includes freight booking, customs and delivery coordination. Dispatch logistics is an effective means of keeping order fulfilment requirements on schedule. They have clear labelling and they track to provide customer satisfaction.

-

Tracking

Orders are assigned with unique numbers and real time updates are given to customers. This increases the reliability of the order processing and order fulfilment, increasing trust in the delivery process. Systems for monitoring are there to ensure smooth operations.

-

Customer Support

Inquiries, returns and feedback are all handled by customer support to increase satisfaction. Customers feel valued and their experience is smooth through the order processing journey if communication is effective through the journey. Loyalty and long term relationship is created through post purchase support.

How to Improve Order Processing?

Automate, improved real time tracking, workforce management optimization, and dispatch logistics, all to improve order processing. Workflows are streamlined and customer centric strategies reduce delays, optimize accuracy and improving overall operational efficiency.

Demand Forecasting

Future needs are predicted using trends and historical data to help order processing to be efficient. It allows businesses to improve their reorder quantity, manage inventory levels, and optimize inventory management for smoother order fulfilment. Accurate forecasting ensures businesses neither overstock nor run out of inventory, improving order accuracy and reducing processing time.

Automation

Automation reduces errors, speeds things up and reduces costs in order processing.It enhances inventory management systems, streamlines the order fulfilment process, and provides real-time updates on order status. By leveraging an automated system, businesses can improve order management, optimize dispatch logistics, and enhance overall efficiency.

Warehouse Management Process

Warehouse Management Systems (WMS) centralise order processing and thus facilitate better inventory tracking, demand forecasting and customer communication. They optimize space, improve packaging logistics and accuracy in order fulfilment The advanced tools enable better operational efficiency.

Reduce Processing Time

Reducing processing time involves real-time order tracking, automation, and optimised order management processes. A streamlined order processing system minimises delays in customer order fulfilment, ensures high order accuracy, and improves operational efficiency. Companies leveraging order management software experience better workflow control and reduced manual processes, leading to faster order entry and reduced labour costs.

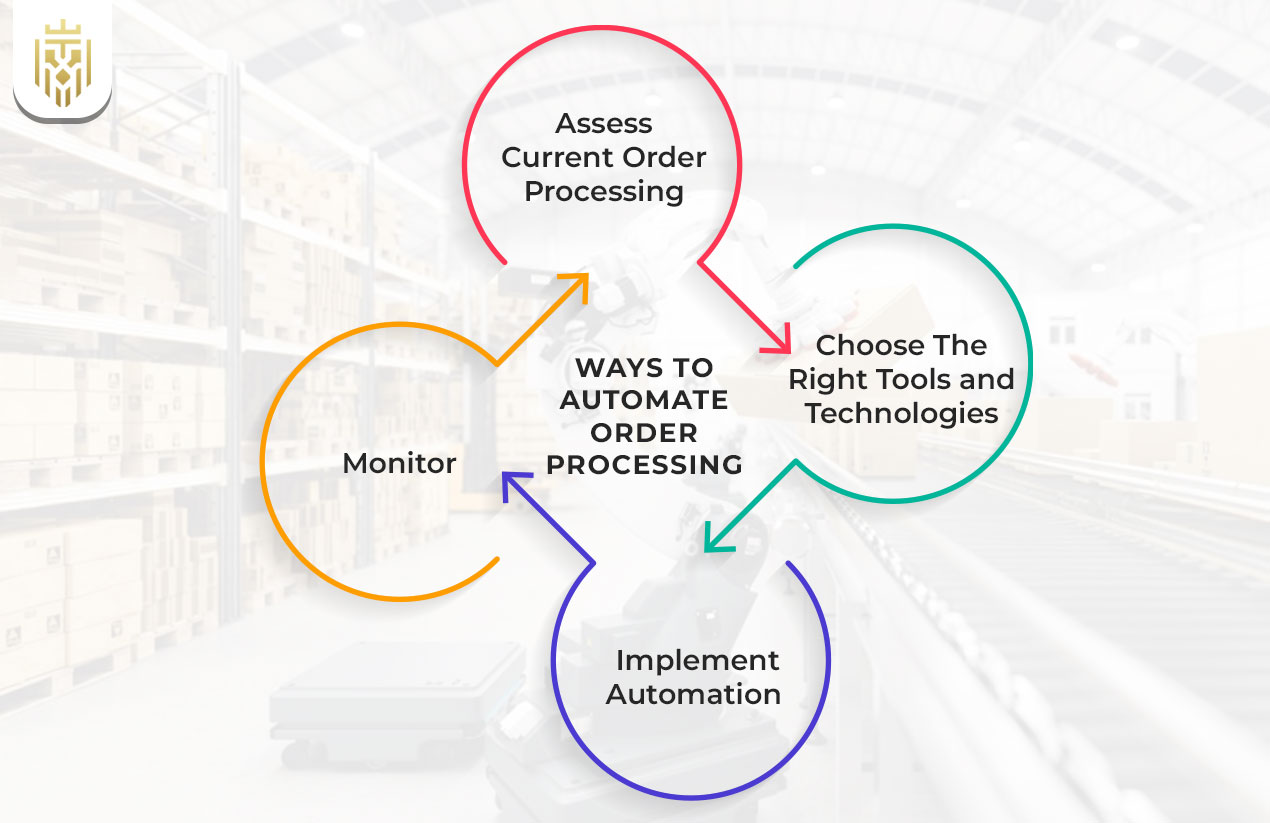

How to Automate Order Processing?

To automate order processing, businesses must follow a structured approach. The process includes assessing current order processing, choosing the right tools and technologies, implementing automation, and continuous monitoring.

-

Assess Current Order Processing

Identifying inefficiencies in order processing systems helps businesses pinpoint areas needing improvement. Evaluating existing inventory management practices and order processing steps ensures a seamless transition from manual to automated order processing.

-

Choose The Right Tools and Technologies

Selecting the right order processing software is crucial for automating sales order handling. Businesses should consider order management systems, inventory management systems, and quality control tools to enhance efficiency. Options include ERP systems for centralised data management, WMS (Warehouse Management Systems) for inventory control, OMS (Order Management Systems) for multi-channel order handling, and RPA (Robotic Process Automation) for automating repetitive tasks.

-

Implement Automation

Successful automation requires seamless integration of new technologies with existing systems like ERP, WMS, and OMS. Additionally, businesses must develop a data migration plan to transfer information from legacy systems without disruptions. Proper implementation ensures smoother workflow, reduces manual intervention, and enhances overall operational efficiency.

-

Monitor

Continuous monitoring of order information and order status ensures smooth operations. Businesses must analyse key performance metrics, refine strategies, and optimize workflows. Automated order processing processes improve overall efficiency, enabling businesses to meet customer demands without delays.

FAQs

1. What is Order Processing?

Managing customer orders from receipt to delivery, including accuracy and reliability is known as order processing. It has multiple steps, such as inventory picking to shipping, with the goal of providing seamless order fulfilment experiences.

2. What are the 5 Steps for Order Processing?

Order receiving, inventory picking, packaging, shipping and tracking constitute the five key steps in order processing. They each ensure timely and accurate order fulfilment, ensuring customer satisfaction and operational efficiency.

3. What are the Order Processing factors?

Product characteristics, workforce productivity, seasonality, order volume, and shipping needs are the key order processing factors. These affect processing efficiency, which in turn affects costs, time lines and the impact of order fulfilment strategies.

4. How long does order processing take?

Product type, industry standards and order complexity all determine order processing time. With simple items taking 1–2 days and more intricate orders needing 3–4 days, we provide smooth order fulfilment.