What is Inventory Reconciliation?

Inventory Reconciliation refers to matching of the inventory records and physical stocks in place. This comparison assists firms in the issue of being accurate and detecting inconsistencies. Through the inventory reconciliation process, business firms can be rest assured they are getting real time inventory level and matching inventories.

How is the Business Approach to Inventory Reconciliation?

Inventory reconciliation is done through a regular scheduling of inventory counts and putting a formal procedure in place by businesses. One of the most common inventory reconciliation cases is to match the sales records, purchase orders, and the stock flows to ascertain as to what is in inventory and to correct any errors as soon as possible to enhance efficiency of the operations.

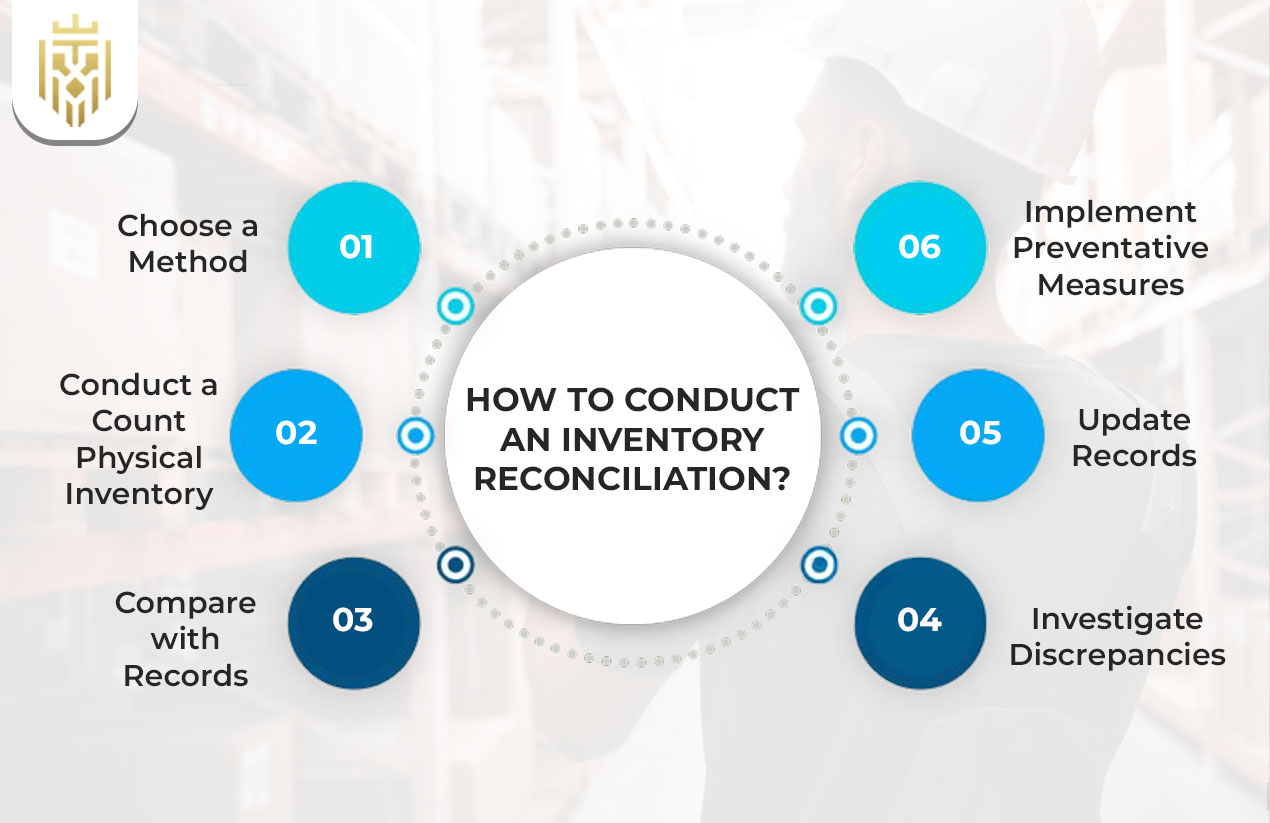

How to Conduct an Inventory Reconciliation?

Conducting an inventory reconciliation requires planning the reconciliation process and assigning the proper resources. Companies usually balance inventory by conducting physical counts, studying variances and adjusting system quantities to true inventory to manage and maintain inventory details efficiently and operationally effective.

Choose a Method

It is important to find an appropriate inventory reconciliation method. Both cycle counting and complete physical inventory reconciliation can be selected by companies depending on complexity and size of inventory. The strategy selected has a direct effect on the efficacy and dependability of the inventory reconciliation procedure and the accuracy of future inventories.

Conduct a Count Physical Inventory

In physical inventory, business count their stocks using manual count to ascertain stock level. This is a necessary measure to identify mistakes or theft or mislocation of products. Good inventory counting helps in the proper reconciliation procedure and enhances the general inventory management options of the company.

Compare with Records

The most important issue of the inventory reconciling process is comparing the records of inventory against the physical stocks. This action will ensure that all entries match with stock availability. Early identification of mismatch assists businesses to prevent stock outs, over stocking, and re-stocking issues in day to day operations.

Investigate Discrepancies

Inventories should determine inconsistencies exposed because of a reconciliation to identify the problem such as pilferage, destruction or clerical errors. Investigation ensures a better result during the reconciliation process and stock information reliability to avoid the loss of finances and the reliability of the stock in all departments.

Update Records

After a physical inventory reconciliation, updating inventory data is important in updating accurate inventory levels in the system. Monthly updates provide the advantage of businesses reconciling their inventory in a proper manner and ensuring that all records that are associated to sales, purchase and the warehouse records are consistent, which makes the whole process of inventory management more robust.

Implement Preventative Measures

The measures taken by business in order to prevent future variance include, routine reconciliation of inventory, security, automation of tracking systems. Such measures protect the correctness of inventory data and assist in simplifying the process of inventory reconciliation, minimising the number of manual errors, and enhancing operation transparency.

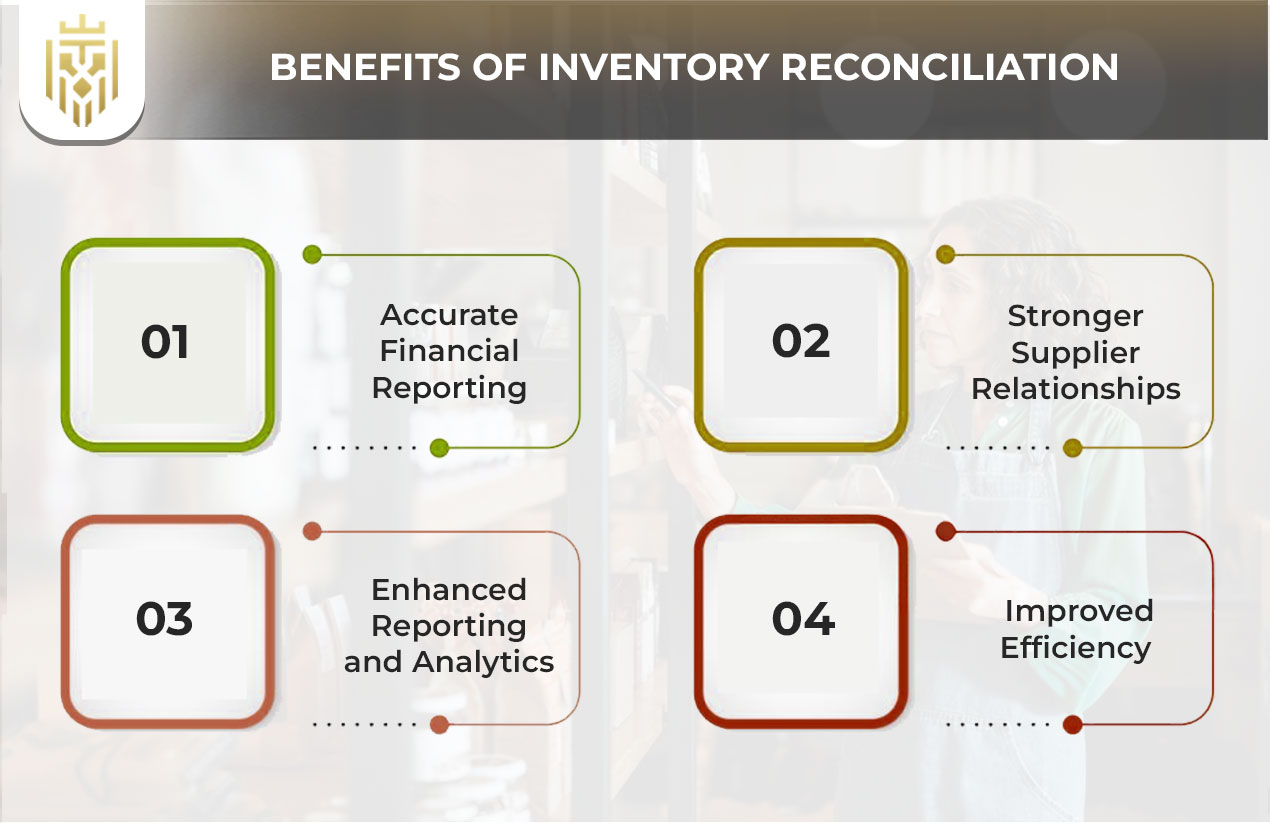

Benefits of Inventory Reconciliation

A good inventory reconciliation has several advantages, such as good stock accounting, reduction in existing financial variances and better planning of resources. Frequent inventory reconciliation enhances reliability of inventory data as well as makes business operations seamless because inventory records will always be free of errors.

Accurate Financial Reporting

Physical inventories are very important in the compilation of proper financial statements. The reconciliation process ensures the consistency in the financial reporting by matching the records with the real stock so that assets and costs are duly recorded in the books of the company and the company is being evaluated on the real basis of its performance.

Stronger Supplier Relationships

The factors above encourage better relationships with the supplier because timely inventory reconciliation will indicate no errors in orders and no discrepancies in stock. Good example of inventory reconciliation is where order mismatches are corrected promptly and this builds trust and long term mutually beneficial supplier relationships.

Enhanced Reporting and Analytics

Regular performance of inventory reconciliation means businesses acquire superior reporting and analytics. Detailed inventory information would be useful to analyse the inventory trends, sales trends, the efficiency of the supply chain amongst others, which managers could use to base their decisions to expand in a more informed and data based way.

Improved Efficiency

Physical inventory reconciliation enables it to streamline the operations in a ware house and save on time wasted on correcting errors. The reconciliation exercise streamlines inventory movement, streamlines inventory storage and accelerates order delivery time culminating in total improvement of overall operating efficiency and customer satisfaction.

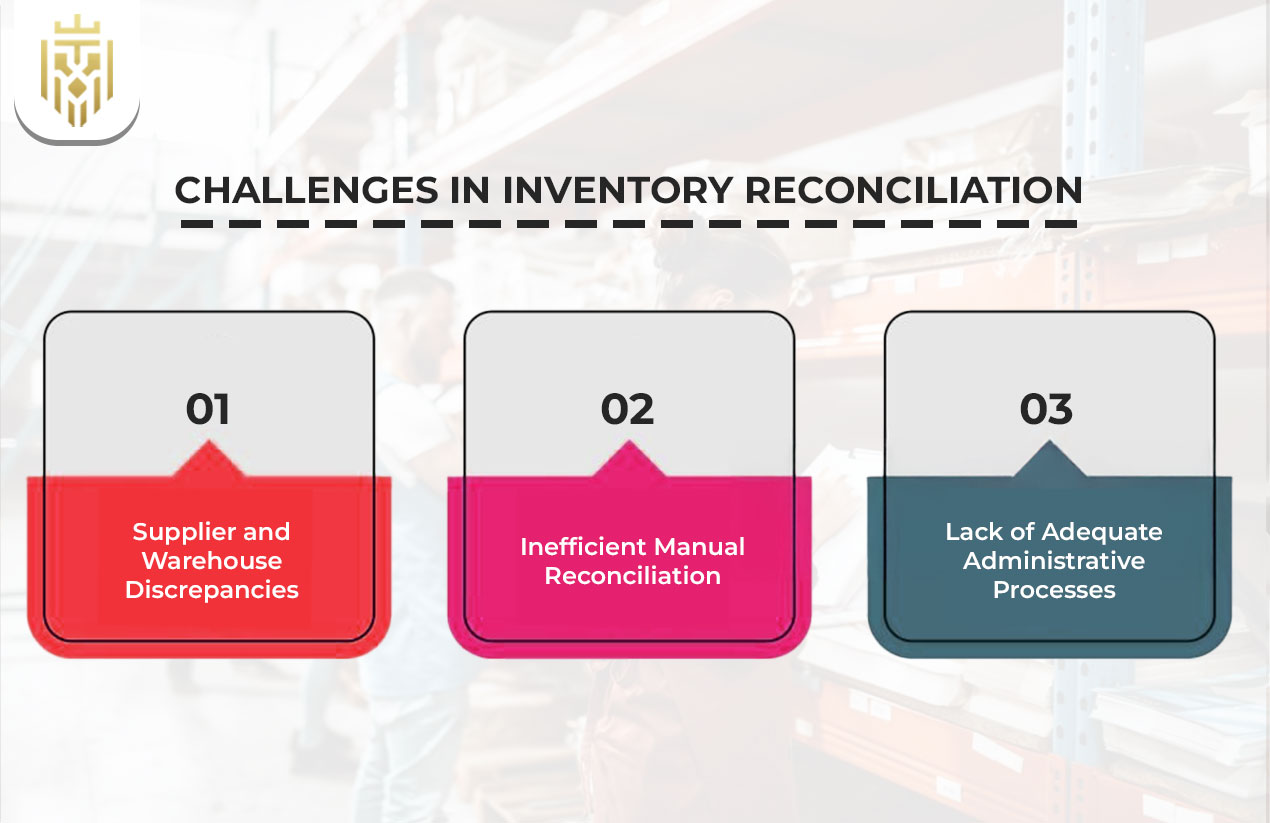

Challenges in Inventory Reconciliation

Among the primary problems of inventory reconciliation is a non-matching inventory count and a sudden stock variation. They may impair supply chains, financial accuracy, and warehouse management and in the long run, regular inventory checks and data verification are critical tools to ensure the success of the company.

Supplier and Warehouse Discrepancies

The mismatch between the suppliers and warehouses is a major setback in inventory reconciliation. These problems can be caused by communication problems, shipping mistakes, or glitches. In order to reconcile their inventory, companies should have a clear procedure in identifying where their shipments are and ensure ensuring delivery confirmation.

Inefficient Manual Reconciliation

Reconciliation of manual inventory can be tedious and error prone. The manual updating of the inventory will lose accuracy and slow down the updates of stock without the assistance of an automated system. Automation of the inventory reconciliation reduces human error and increases efficiency in real-time tracking of the inventory.

Lack of Adequate Administrative Processes

The absence of administrative workflows may create obstacles in the way of the reconciliation. Unless controlled, reconciliation of physical inventory can result in wrong figures, which results in unreliable records. Creating a sound inventory procedure will aid in keeping track and will make the records kept consistent throughout the organization.

Tools and Technologies for Inventory Reconciliation

Companies use sophisticated instruments in carrying out inventory reconciliation. Such processes as barcode scanners, RFID, and automated software make the inventory count much smoother than before and make the reconciliation process much easier, providing visibility in real-time, decreasing manual operations, and potentially decreasing stock errors.

Barcode Scanners and RFID Devices

Bar code scanners and RFIDs simplify the job of tracking physical inventory. These tools improve the process of inventory reconciliation by making it automated thus reducing the number of manual errors as well as enhancing the accuracy of the inventory. They also enable speedier inventory check and lean stock keeping.

Point of Sale (POS) Systems

The introduction of Point of Sale (POS) systems would help in this regard as these systems update the inventory records as quickly as possible with every purchase. The accuracy of inventory data provided with the help of POS solutions also contributes to efficient reconciliation of inventory, to the maintenance of real-time stock levels that can always be considered accurate.

Cycle Counting Software

The cycle counting software helps in reconciling the physical inventory as they are reports on the regular inventory that is taken without interfering with the normal operations. This technology makes the inventory reconciling easier, enhances inventory accuracy, and makes it possible to update in time, minimising the risk of major discrepancies in stock.

Workflow Automation Tools

Automation tools which can be used in workflow can greatly facilitate the inventory reconciliation process. These tools support effective management of the reconciliation process due to automation of inventory updates, error detection, reporting leads to improved inventory control, and less workload on the warehouse personnel.

FAQs

1) What is Inventory Reconciliation?

Inventory Reconciliation refers to matching of the inventory records and physical stocks in place. This comparison assists firms in the issue of being accurate and detecting inconsistencies. Through the inventory reconciliation process, business firms can be rest assured they are getting real time inventory level and matching inventories.

2) What is the Reconciliation Process?

The reconciliation process entails, comparing the inventory record data, or actual physical stock via inventory counts, locating the discrepancies, and adjusting the records. This gives proper reports, avoids losses, and assists in business reconciliation, thus its inventory is properly reconciled to allow smooth operations and stock management.

3) How to Conduct an Inventory Reconciliation?

Conducting an inventory reconciliation requires planning the reconciliation process and assigning the proper resources. Companies usually balance inventory by conducting physical counts, studying variances and adjusting system quantities to true inventory to manage and maintain inventory details efficiently and operationally effective.

4) What are the benefits of Inventory Reconciliation?

A good inventory reconciliation has several advantages, such as good stock accounting, reduction in existing financial variances and better planning of resources. Frequent inventory reconciliation enhances reliability of inventory data as well as makes business operations seamless because inventory records will always be free of errors.