What is Dynamic Slotting?

Dynamic slotting is a new technique whereby the position of the products within a warehouse system is dynamically adjusted to the demand and movement. It is more efficient than the static ones by minimising picker travel time and optimising the utilisation of warehouse space by using intelligent and dynamic slotting plans.

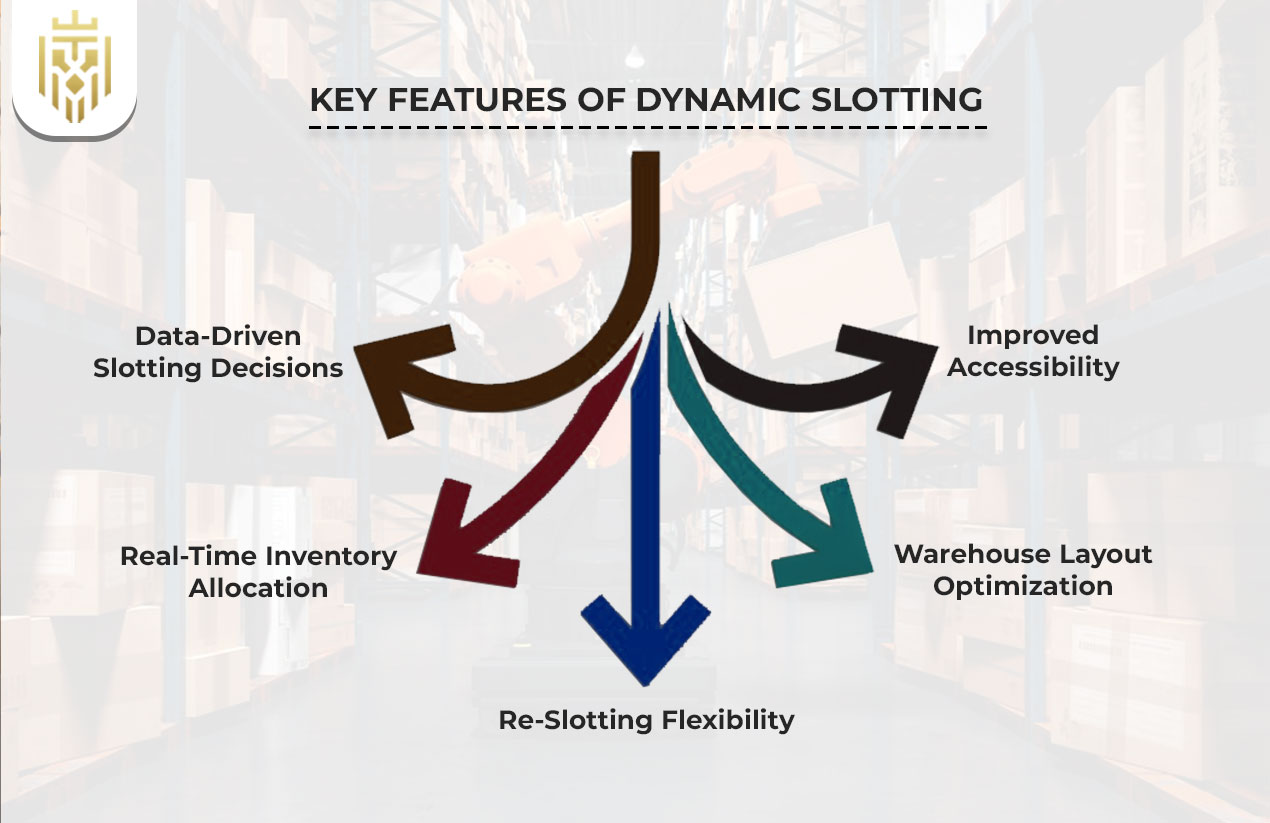

Key Features of Dynamic Slotting

The dynamic warehouse slotting system concerns responsiveness, automation, and adaptability. It facilitates real-time changes, strategic placements, and simplified procedures. These are sophisticated warehouse slotting solutions that enable businesses to adjust to changing customer needs as well as guarantee warehouse slotting best practices and general enhancement in the productivity of the operational process.

Data-Driven Slotting Decisions

The analysis of data is important in warehousing setup and slotting. Managers can make informed decisions by using demand forecasting and order history. This makes sure product placement helps to enhance the efficiency of picking in the warehouse and improves warehouse space optimisation techniques to highly efficient slotting adjustments.

Real-Time Inventory Allocation

Dynamic slotting in a warehouse implies continuous allocation of products according to the demand in real time. This reduces the number of bottlenecks and strategic location of popular items and enhances picker speed. These types of adjustments are the basis of warehouse slotting best practices in contemporary logistics operations.

Re-Slotting Flexibility

The main strength of a dynamic warehouse slotting system is its flexibility. Whenever changes in demand are experienced, businesses are able to reslot items. The dynamic solution assists in enhancing warehouse picking efficiency and preventing space limitations to increase flexibility and warehouse setup and slotting optimisation to enable long-term scalability.

Optimization of Warehouse Layout

Good design layout is in harmony with best practices and warehouse slotting best practices. Frequently selected products can be placed closer using continuous re-slotting, which simplifies operations. These practices facilitate the optimisation of space in warehouses to enhance the travel routes and overall performance of the warehouse in various industries.

Improved Accessibility

Better access using warehouse slotting and set-up will be used so that high-demand items are as near to packing stations as possible. This directly improves productivity, saving on unnecessary travelling. These sophisticated warehouse slotting systems enable quicker order fulfilment and optimal use of the warehouse space methods to achieve an excellent level of inventory accessibility.

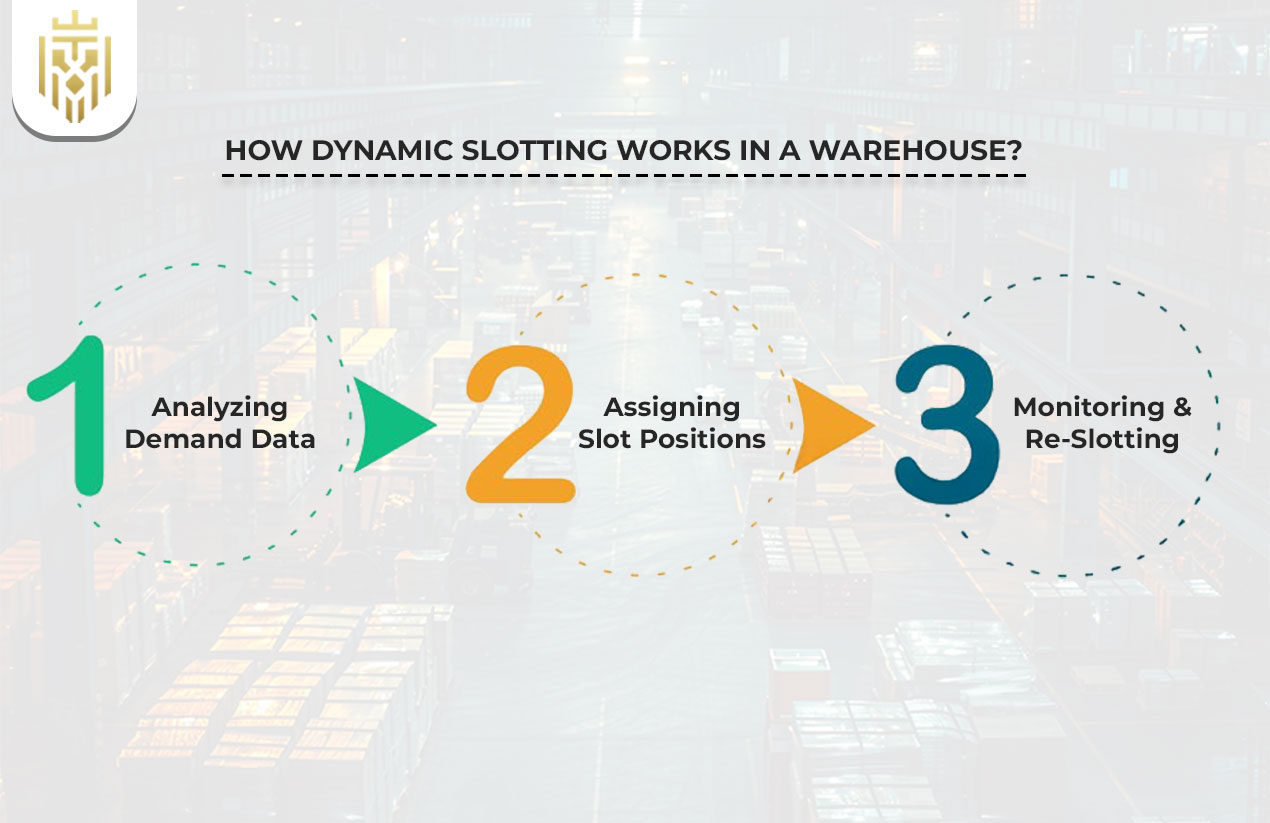

How Dynamic Slotting Works in a Warehouse?

A dynamic warehouse slotting system is one that continually optimises the location of products using data insights. When the managers manage inventory flow by matching it with demand patterns, they enhance the use of warehouse space and best practices of warehouse layout to maximise efficiency and responsiveness in the distribution centres.

Analyzing Demand Data

The process of analysing demand data allows managers to use dynamic slotting within warehouse systems effectively. Products are given the best slots, with knowledge of order frequency and seasonality. This guarantees the effective application of warehouse space utilisation techniques, enhancing accuracy and facilitating easy picking and packing.

Assigning Slot Positions

Slotting optimisation and warehouse setups involve slot position allocation. Products will be strategically located depending on demand frequency, size, and weight. This guarantees enhancement of the efficiency of picking in a warehouse, minimises congestion, and is in line with best practices of slotting in a warehouse in the contemporary logistics networks.

Monitoring & Re-Slotting

Continuous monitoring assists a dynamic warehouse slotting system since it determines demand variations. Re-slotting is also done fast when needed. This is the core of sophisticated warehouse slotting systems which aid companies to improve their productivity and secure efficient optimisation strategies for warehouse space.

Dynamic vs Static Slotting

Dynamic slotting, in contrast to static slotting, is continuously adjusted to the shifting inventory trends. Whereas a static method provides consistency, it will be inflexible. An effective warehouse slotting system is dynamic, which guarantees real-time adjustments, improving warehouse slotting best practices and ensuring efficient use of warehouse space in complex operational settings.

Benefits of Dynamic Slotting

Warehouse dynamic slotting enhances efficiency through order accuracy, lessening travel time and optimising the use of warehouse space. It advocates advanced warehouse slotting solutions, which guarantee scalability, flexibility, and smooth operations in the contemporary logistics settings.

Faster Order Picking & Packing

The major advantage of dynamic slotting is to improve picking efficiency in the warehouse. Highly demanded products are placed nearest to workers, so workers can access them much faster and travel longer distances. These are practices that go hand in hand with the warehouse slotting and configuration needs to maximise throughput in operations.

Better Storage Optimization

Companies become more efficient in warehouses by combining warehouse space optimisation solutions. Dynamic slotting of the warehouse ensures all shelves, racks and bins are optimally used. This saves on wasted space and promotes continuous improvement as well as ensuring more effective utilisation of storage in the warehouse setup settings.

Flexibility for Sudden Demand Changes

E-commerce requires flexibility since demand changes swiftly. An efficient slotting system in a warehouse is dynamic, and the placements are adjusted instantly. These complex warehouse slotting solutions eliminate disruption, aid warehouse configuration and slotting optimisation, and allow enterprises to remain robust in the event of unexpected order influx.

Increased Warehouse Efficiency

Dynamic slotting enhances overall efficiency during the warehouse operations. Optimised product position and minimised travel and congestion lead to smooth workflows. Warehouse slotting best practices can enable firms to attain long-term competitiveness, as well as maintain continuous use of the warehouse space in response to every demand situation.

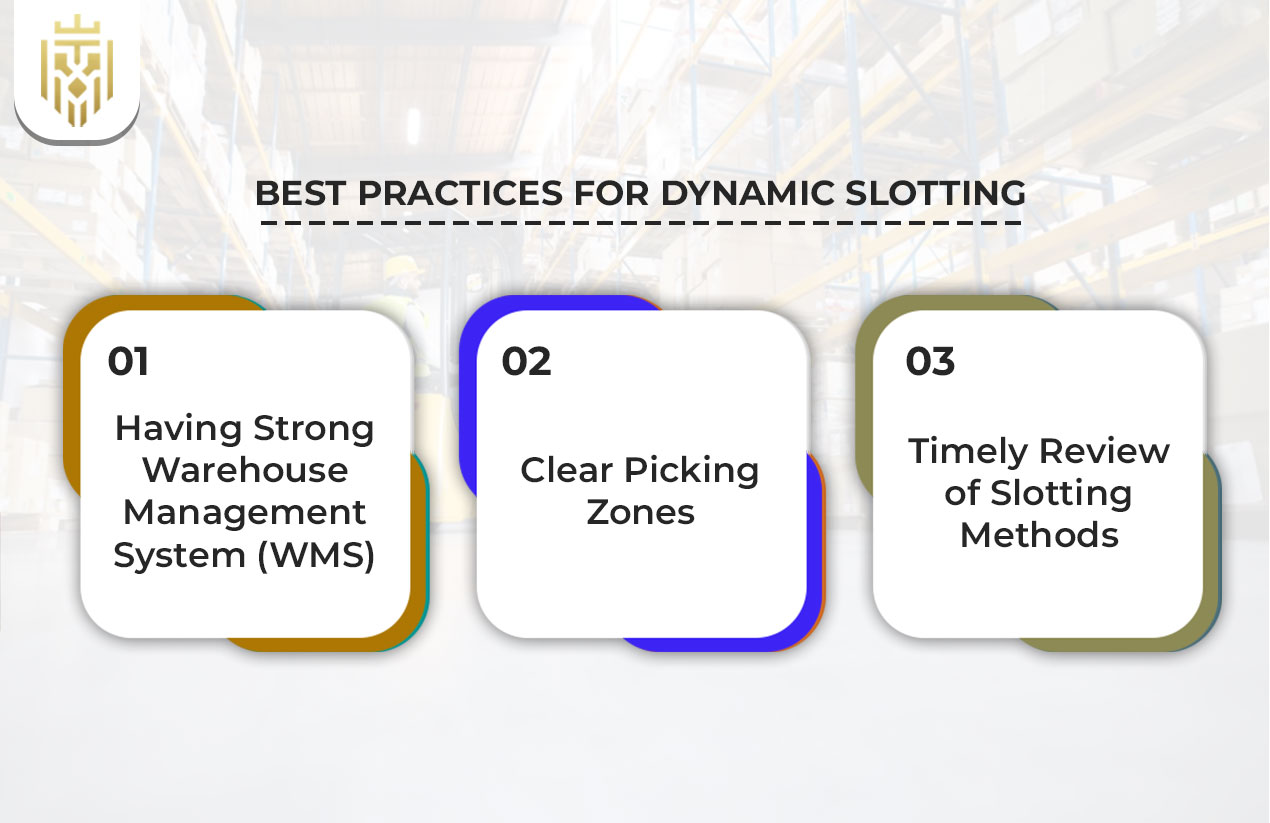

Best Practices for Dynamic Slotting

The best practices of dynamic slotting are timely reviews, established picking areas, and strong WMS integration. These strategies facilitate warehouse arrangements as well as slotting optimisation, which allow efficient layout, smarter distribution, and other enhanced approaches to optimisation of the warehouse space to sustain productivity.

Having Strong Warehouse Management System (WMS)

A sound WMS complements warehouse configuration and slot optimisation. The automation of work, minimisation of errors, and the effective implementation of warehouse space utilisation methods are achieved by combining high-level warehouse slotting solutions and technology. The combination results in efficient, effective, and smooth operations in the warehouses in general.

Clear Picking Zones

Clear picking areas can help to enhance the efficiency of picking in the warehouse. The workers will be able to work in particular areas; hence, there will be less congestion and confusion. This is one of the best practices of warehouse slotting that gets good layouts that make operations in an active warehouse slotting system less complicated.

Timely Review of Slotting Methods

Reviewing of slotting regularly is in line with the best practices of warehouse set-up. Tests see to it that the methodologies are not outdated. Such reviews enable the optimisation of the processes of space in the warehouse and ensure a level of accuracy in the warehouse slotting and setup to support long-term adjustability and the general efficiency of the warehouse.

Challenges in Dynamic Slotting

A dynamic warehouse slotting system is costly, technology-intensive, and WMS-dependent to implement. Complexity increases in large facilities requiring accurate warehouse setup and optimisation of slotting whilst ensuring that the best practice of warehouse slotting is upheld to minimise inefficiencies.

Expensive Setup & Technology

A dynamic warehouse slotting system can be an expensive undertaking in terms of software, training and automation requirements. These sophisticated warehouse slotting systems are costly, but they ultimately prove to be cost-effective in the long term by increasing efficiency and improving the use of warehouse space in multifaceted facilities.

Highly Dependent on WMS

WMS is incredibly essential to dynamic slotting. In the absence of good systems, it is a challenge to set up warehouses and optimise slotting. High WMS makes sure that there is proper tracking of inventory and that it follows the best practices in warehouse slotting to create efficiency and to make smooth changes to meet changing product demands.

Complexity in Large Warehouses

Big warehouses are complicated during the dynamic slotting of the warehouse activities. The staging of layouts, workers and automation must be done carefully. Warehouse slotting best practices can ensure that businesses overcome the challenges and attain balanced warehouse space optimisation approaches to achieve a higher degree of accuracy in large-scale environments.

Future Trends in Dynamic Slotting

It is foreseen that in the future, dynamics in slotting warehouse systems will change through automation, AI, and IoT. The use of Smart WMS will maximise the use of warehouse space, and advanced warehouse slotting solutions will lead to predictive placement, flexibility, and increased efficiency in global supply chains.

Role of Automation, AI, IoT

The future of dynamic warehouse slotting systems is AI, IoT and automation. Such technologies provide predictive analytics and state-of-the-art warehouse slotting solutions. Together, they will underpin warehouse slotting and set-up enhancements, making it possible to make smarter use of warehouse space and smooth adaptations to more contemporary logistics.

Smart WMS Driven Dynamic Slotting System

Smart WMS guarantees really dynamic slotting of warehouse processes through automation of decisions on placing. It is an accurate, technology-driven method that is used to streamline the process of warehouse layout and slotting. Warehouse slotting best practice will help businesses to achieve long-term growth in the form of data-driven operations that are automated.

FAQs

1. What are the main benefits of dynamic slotting in warehouse management?

Its key advantages are enhanced efficiency of picking in the warehouse, minimised travelling time, increased accuracy and improved use of warehouse space through flexible advanced warehouse slotting systems that respond to the fluctuating inventory needs.

2. How does dynamic slotting optimize space within warehouse storage?

Dynamic slotting in the warehouse maximises the capacity by reassigning the items according to the demand. This guarantees efficient warehouse space optimisation techniques, eliminates unused storage, and aids in the ongoing warehouse establishment and slotting optimisation plans.

3. How important is technology in the warehouse slotting and setup?

Warehouse slotting and setup cannot be done without technology that will allow real-time adjustments via WMS. Strong systems increase accuracy, maintain warehouse slotting best practices, and increase efficiency with dynamic warehouse slotting system capabilities.

4. Can dynamic slotting benefit smaller warehouses?

Yes, smaller warehouses not only enjoy the benefits of warehouse slotting best practices in optimization of layouts, better way of utilising warehouse space and simpler dynamic warehouse slotting system, which reduces congestion and improves accessibility and operational efficiency.