What is Bill of Materials (BOM)?

A Bill of Materials (BOM) is a complete list that gives detailed information about all the raw materials, components, subassemblies, and parts required to manufacture a product. It is like a product recipe, BOM outlines every raw material and quantity needed to create the final product. BOM is often used for communicating between manufacturing partners or is restricted to a single manufacturing plant.

In supply chain management, the BOM plays an essential role by assuring that procurement, production, and logistics teams all work with the same group of accurate information. Without it, businesses’ risk rate increases due to delays because of stockouts, and inefficiencies. A well-prepared BOM provides transparency, minimizes errors, and keeps production on track.

Bill of Material Format

Bill of Materials is usually presented in tabular format, with each row representing a component, and columns showing its details. While the exact format may vary for different companies and industry, although there are certain elements that are considered as crucial and can be seen common.

Part Number

In BOM, each component or material are assigned with a unique identifier called the part number. This prevents confusion between similar items and ensures consistency across procurement, manufacturing, and inventory records.

Part Name

Part name is a descriptive title for the component that makes it easy for the users to recognize without fully depending on the part number.

Description

A description is the part of the BOM that provides more details about the part, such as size, color, material type, or specification, ensuring stakeholders have complete transparency and clarity.

Quantity

The quantity section specifies the units of each part that are required for one finished product. Quantity helps in avoiding shortages during production and ensures accurate procurement planning.

Unit of Measure

Each item needs a unit of measure, such as pieces, meters, kilograms, or liters, so that procurement and production can align on ordering and usage.

Procurement Type

The procurement type shows whether a part is purchased externally from suppliers or manufactured internally. This helps the teams to coordinate sourcing decisions effectively.

Cost Information

Cost Information for each part contributes to better financial clarity. It helps in budgeting, cost analysis, and identifying opportunities for savings.

Supplier Information

The Bill of Materials also lists supplier information, such as vendor name and contact details, which assures sourcing is efficient and reduces the time needed to reorder.

Assembly Level

Some products are built in various stages. The assembly level depicts where the product structure’s part belongs, whether it’s part of a subassembly or the final assembly.

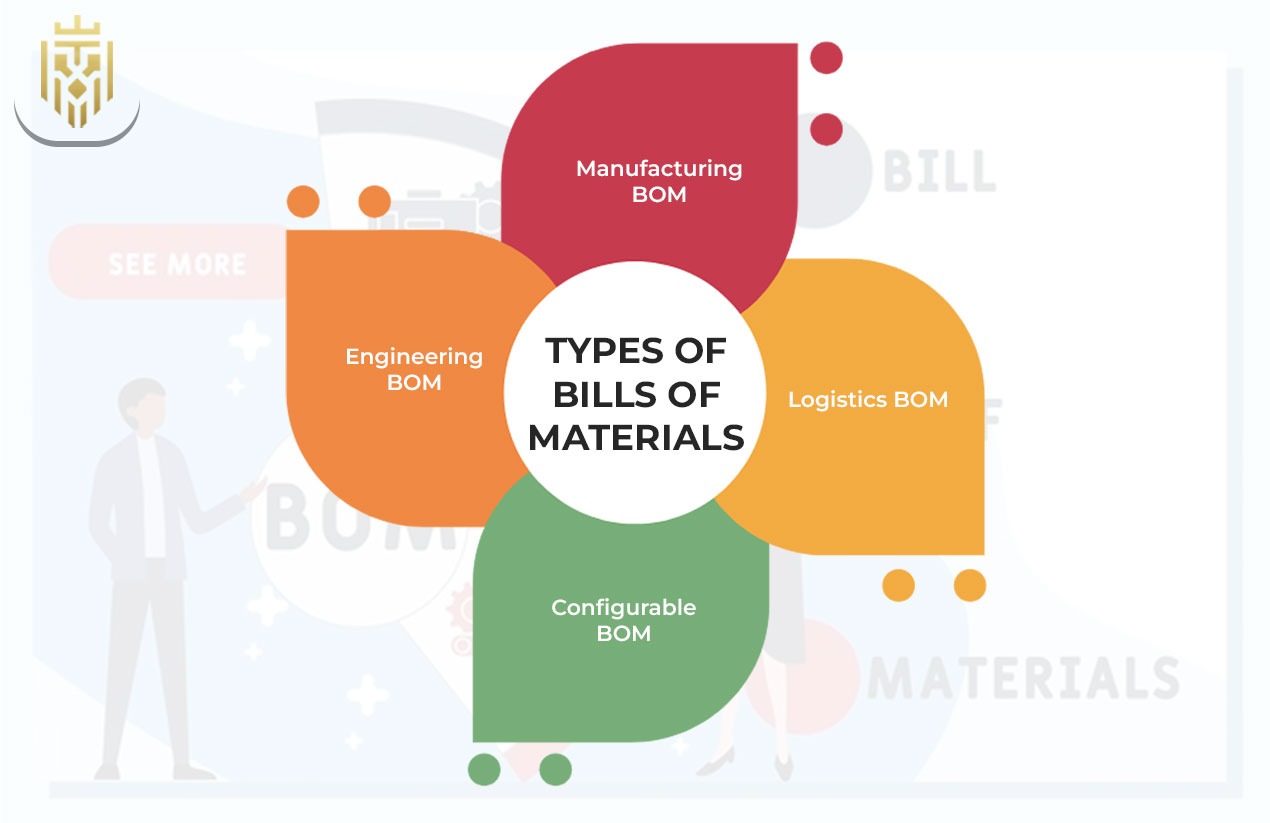

Types of Bill of Materials

Different businesses and industries demand distinguished BOM structures. The four most common types are:

Engineering BOM

Engineering BOM, also know as EBOM, is made during the designing phase of a product. It has details of all the components by the engineering team and is often created using CAD or design software.

Manufacturing BOM

Manufacturing BOM or MBOM is created for production purposes. MBOM includes all the items required to actually build the product, along with instructions for manufacturing and assembly.

Logistics BOM

A Logistics BOM focuses on packaging, transportation, and distribution needs. It lists items related to packaging materials, pallets, and handling instructions to ensure the product reaches customers safely.

Configurable BOM

A Configurable BOM is used for products that come in different variations or customizations, like cars or electronics. It allows manufacturers to manage multiple versions of the same product without creating separate BOMs for each variation.

Bill of Materials in Supply Chain Management

In Supply management, the Bill of Materials serves as a bridge in connecting procurement, production, inventory, logistics, and finance. Here’s how it fits into the supply chain:

Procurement & Sourcing

Procurement teams depend on the BOM to determine what needs to be purchased, in what quantity, and from which suppliers. This assures cost-effective sourcing and prevents overstocking or shortages.

Production Planning

The BOM acts as the production roadmap for manufacturing teams. It gives the outline of the exact components needed, helping in scheduling, resource allocation, and ensuring production lines run smoothly.

Inventory Management

Inventory management uses BOM to track stock levels of raw materials and components. This helps them to maintain just the right amount of inventory, which keeps production going without tying up excess capital.

Logistics & Distribution

A logistics BOM delivers clarity on packaging and handling necessities, which ensures products are shipped efficiently and arrive in good condition.

Cost Analysis

The BOM gives businesses deeper insights into production expenses with breaking down the cost analysis of every component. This helps in product pricing competitively while protecting profit margins.

Benefits of Bill of Materials

BOM can be a very powerful tool if managed appropriately. It can transform supply chain performance.

Improves Efficiency

BOM improves efficiency. With its clear lists of parts and materials, every department works in sync, which minimizes delays and streamlines workflows. It removes guesswork, helps in smooth and effortless coordination, and ensures production runs without uncertain interruptions.

Controls Cost

Accurate procurement planning and cost information helps businesses avoid needless expenses and negotiate better with suppliers. Over time, this allows companies to identify cost saving opportunities and improve profitability.

Reduces Errors

A well-structured BOM avoids mistakes like ordering wrong parts, using unfitting materials, or miscalculating quantities. By acting as a single source of fact, it minimizes rework, waste, and quality issues in the final product.

Boosts Supply Chain Visibility

As the stakeholders from procurement to logistics work off the same document, the BOM improves visibility and transparency across the supply chain. This alignment enhances decision-making and builds flexibility against disruptions.

Challenges in Managing BOM

BOM has a lot of advantages, but managing this can be challenging if not handled carefully.

Complexity of Products

Modern products often contain numerous parts, making BOMs for each is tremendously complex to manage. Coordinating across various assemblies, suppliers,and product variations needs advanced systems and accurate surveillance.

Data Inaccuracy

Data inaccuracy can highly impact BOM. Errors in data entry, outdated records, or miscommunication between teams can trigger inaccurate BOMs and costly mistakes. Small mistakes can also lead to delays, wrong sourcing, or quality issues that surge through the supply chain.

Integration Issues

If BOMs aren’t incorporated with ERP or supply chain software, data silos can happen, minimizing efficiency and transparency. Lack of alliance forces teams to depend on manual updates, which eventually increases the chance of duplication and delays.

Version Control

Products evolve with the changing times. Without accurate version control, businesses risk using outdated BOMs, which can lead to production delays or product recollection. Having a clear revision process assures teams always work with the most current and appropriate information.

Best Practices for Bill of Materials Management

To increase the value and use of BOM, companies need to manage it strategically. Inadequately maintained BOMs can create an inability, while best practices ensure accuracy, visibility, and effortless collaboration across the supply chain. The Following are some proven methods businesses can adopt:

Leverage BOM Software

Using a specially designed BOM helps automate updates, minimize errors, and enhance collaboration across teams. These tools also organize with other systems, allowing real-time visibility and faster decision-making.

Regular Updates & Audits

BOMs needs to be reviewed and updated on a frequent basis to reflect design changes over time, supplier updates, or shifts in production requirements. Routine audits assure accuracy and prevent outdated information from causing costly delays or mistakes.

Standardize BOM Structure

A standardized and consistent format makes BOMs easier to read and understand, which also reduces confusion and assures that all stakeholders can depict them accurately. Standardization also simplifies training for new employees and improves collaboration between departments.

FAQs

1) How does a Bill of Materials differ from a parts list?

A parts list is a simple record of components, while a BOM is more detailed, including quantities, sourcing details, and cost information.

2) Which industries rely most heavily on complex BOM structures?

Industries like automotive, electronics, aerospace, and construction use highly complex BOMs due to the large number of components involved.

3) Can a Bill of Materials be used in service-based industries?

Yes. While BOMs are most common in manufacturing, service industries like IT and telecom use a similar concept to outline service components or workflows.

4) How do companies handle multi-level BOMs in global supply chains?

They often use advanced ERP systems that allow for layered BOMs, ensuring accurate planning across multiple suppliers, production facilities, and regions.