Backhaul and Headhaul in Logistics

Headhaul and backhaul shipping have been important in logistics management to make transport efficient and cost-effective. The two movements are balanced to provide freight routes in the supply chain to ensure that vehicles run effectively with a minimum number of empty miles, which are directly affected.

What Is Headhaul in Logistics?

Headhaul freight movement is the main journey between the source and the delivery point and is normally loaded with goods. Effective headhaul route optimization minimises travel time and maximises profitability. It is the forward freight transportation process in logistics and forms the forward freight transportation process in logistics, which ensures the stability of supply chains.

What Is Backhaul in Logistics?

Backhaul in logistics deals with the travelling back of a truck, which is usually involved in the transportation of goods back to the place of origin. The backhaul transport process averts empty miles, enhances profitability and also improves logistics management. Understanding backhaul meaning in logistics aids in the capacity optimisation of the logistics, fuel efficiency, and sustainability in the freight operations.

Headhaul vs Backhaul Shipping

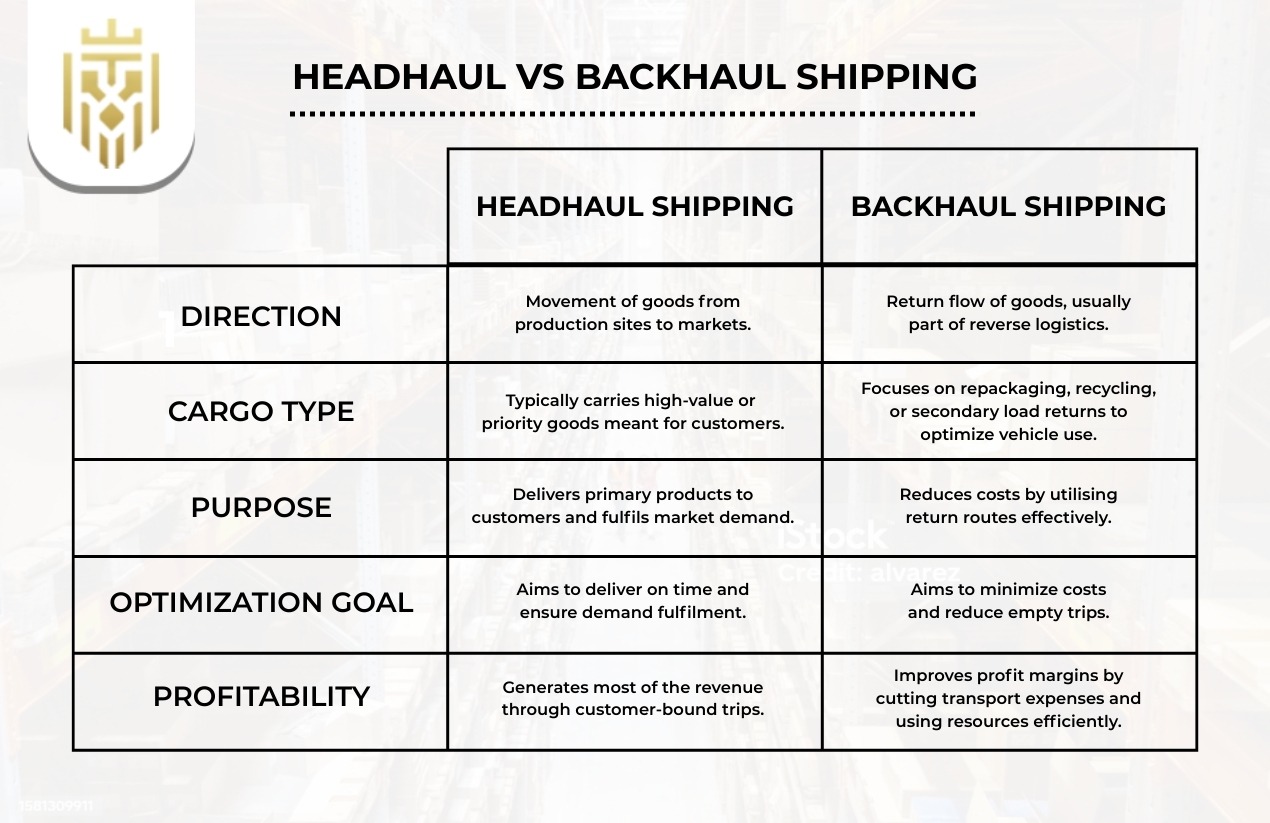

The headhaul vs backhaul shipping comparison reveals the differences in operations based on direction, cargo volume and profitability. Although headhaul can be used to transport major freight, the backhaul can be used to transport vehicles back in an efficient manner. The combination of the two maximises the transport efficiency of the freight carriers and the logistics systems in general.

Direction

Direction is an important factor in headhaul and backhaul shipping: headhaul is the transportation of goods to markets that are produced at production sites, and backhaul transportation is a return flow of goods, usually part of reverse logistics. There should be efficient planning of routes between these directions to minimise empty miles and improve the performance of the supply chain.

Cargo Type

High-value or priority goods are typically transported using headhaul freight, and the backhaul logistics strategy aims at the repurposing of packaging, recycling or secondary load returns. Cargo mix in freight transport helps enhance the performance of freight transport and contributes to the sustainability of logistics management in complicated networks of carriers.

Purpose

The headhaul shipping process has the primary focus on the delivery of the products to the customers, and the backhaul in logistics is directed at the decreasing of the costs of the backhaul by making use of the return routes. The two are necessary in the effective freight carrier operation and the economical supply chain tactics.

Optimization Goal

The optimisation of headhaul routes is aimed at delivering on time and satisfying demand, whereas the backhaul transport process aims at minimising costs and lowering trips with no need. The joint flow optimisation optimises the route planning and the logistics management in general in an interconnected supply chain.

Profitability

The majority of the revenue is accrued by headhaul trips, and the margins are increased by the backhaul transport reducing transport expenses by utilising resources more effectively. The option of operating with both guarantees increased profitability and efficiency in the logistics management.

Reverse Logistics and Backhaul Integration

Backhaul transport integrated with the reverse logistics will enable the companies to use the same routes to recycle, repair, or make returns. This strategy helps reduce empty miles, promote supply chain synchronisation, and provide sustainable freight operations with better route and asset management.

Reduce Duplication of Routes

Integration of reverse logistics with backhaul of logistics assists in the elimination of unnecessary journeys. This method will lower the cost of backhaul, consume less fuel, and enhance the transport efficiencies, allowing the carriers to plan more efficient routes and generate profits.

Optimise Freight Transport

An improvement in freight transport by way of synchronised headhaul and backhaul shipping will decrease idle time and provide efficient flow of the supply chain. This is to ensure the optimization of headhaul routes, reduction of empty miles and maximisation of vehicle utilisation.

Benefits of Backhaul

The backhaul transport process offers significant advantages that include cost savings, better usage of assets, and sustainability. Backhaul improves balance and efficiency of the supply chain in the management of logistics by means of loaded returns and decreased idle truck mileage.

Improved Asset Utilization

Backhaul in logistics provides trucks to be loaded when they are back, which maximises the use of the assets. This results in reduced empty miles, improved route planning, and increased efficiency of freight carriers in the entire supply chain.

Cost Reduction

Backhaul transport reduces transport cost, fuel consumption, and maintenance costs through avoiding unnecessary trips. These savings transform backhaul logistics strategy into a vitally necessary instrument to streamline the overall supply chain efficiency.

Enhanced Supply Chain Connectivity

Backhaul transport is also effective in enhancing the connectivity of the supply chain by aligning the pickups and the return routes. This integration has made freight transport coordination smoother and improved the logistics management outcomes.

Sustainability Gains

Backhaul logistics strategy facilitates the concept of sustainability through the minimisation of carbon emissions and empty miles. The effective transportation process helps to cover the environmentally friendly operations and provides the sustainability of the supply chain programmes.

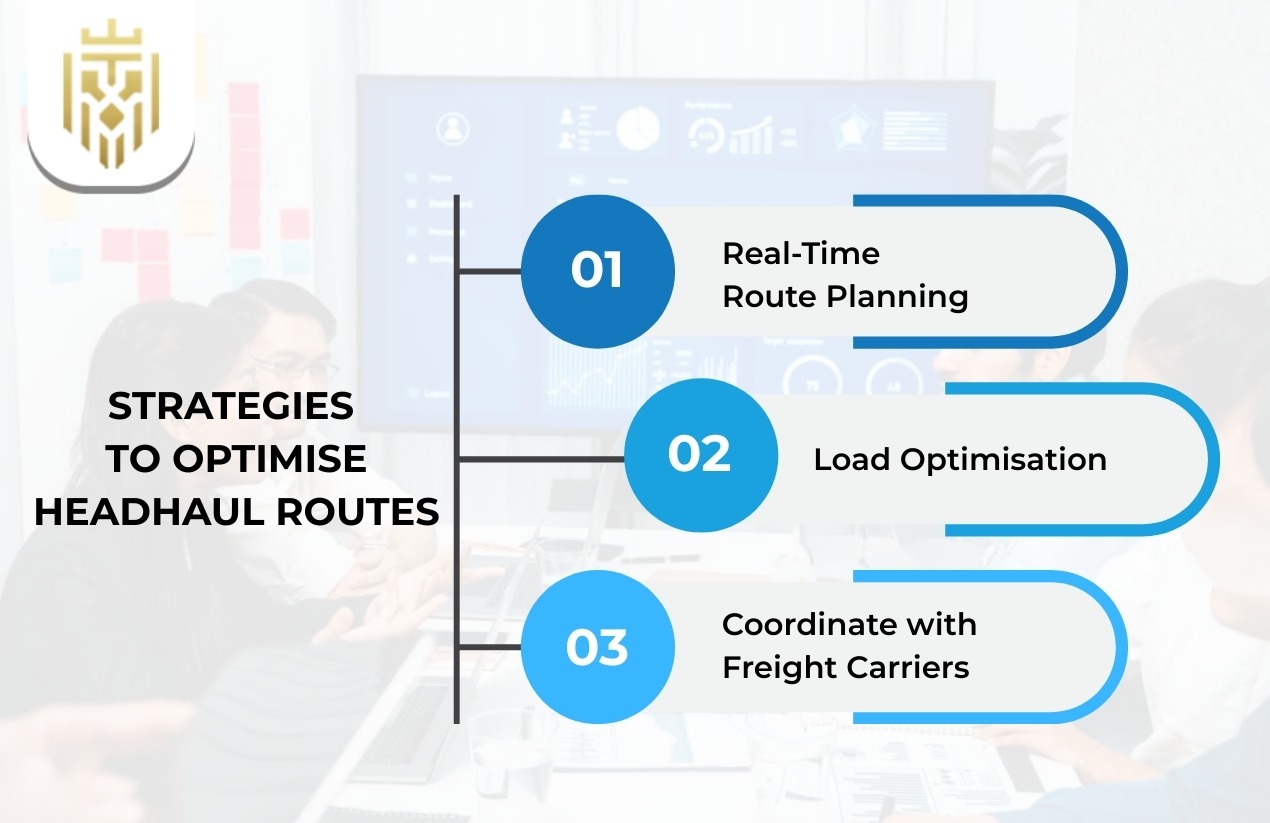

Strategies to Optimise Headhaul Routes

Headhaul route optimisation increases freight efficiency, minimises delays and maximises carrier profitability. Leverage tools of route planning and logistic software are also used by companies in order to optimise the transportation of headhaul freight and reduce costs of transportation and delivery in time.

Real-Time Route Planning

Real-time route planning systems are useful in optimising the headhaul routes to achieve efficiency and reliability. The incorporation of data-driven solutions increases the efficiency of transport and can keep up with the dynamic requirements of the supply chain.

Load Optimisation

Load optimisation is applied in the headhaul shipping process, and it makes sure that trucks are utilised fully. Effective truckload planning is cost-effective, improves the movement of freight, and is better in terms of supply chain management.

Coordinate with Freight Carriers

By having good coordination with the freight carriers, it is possible to schedule and optimise the routes easily. This enhances the movement of freight in the headhaul and makes the performance of the supply chain consistent.

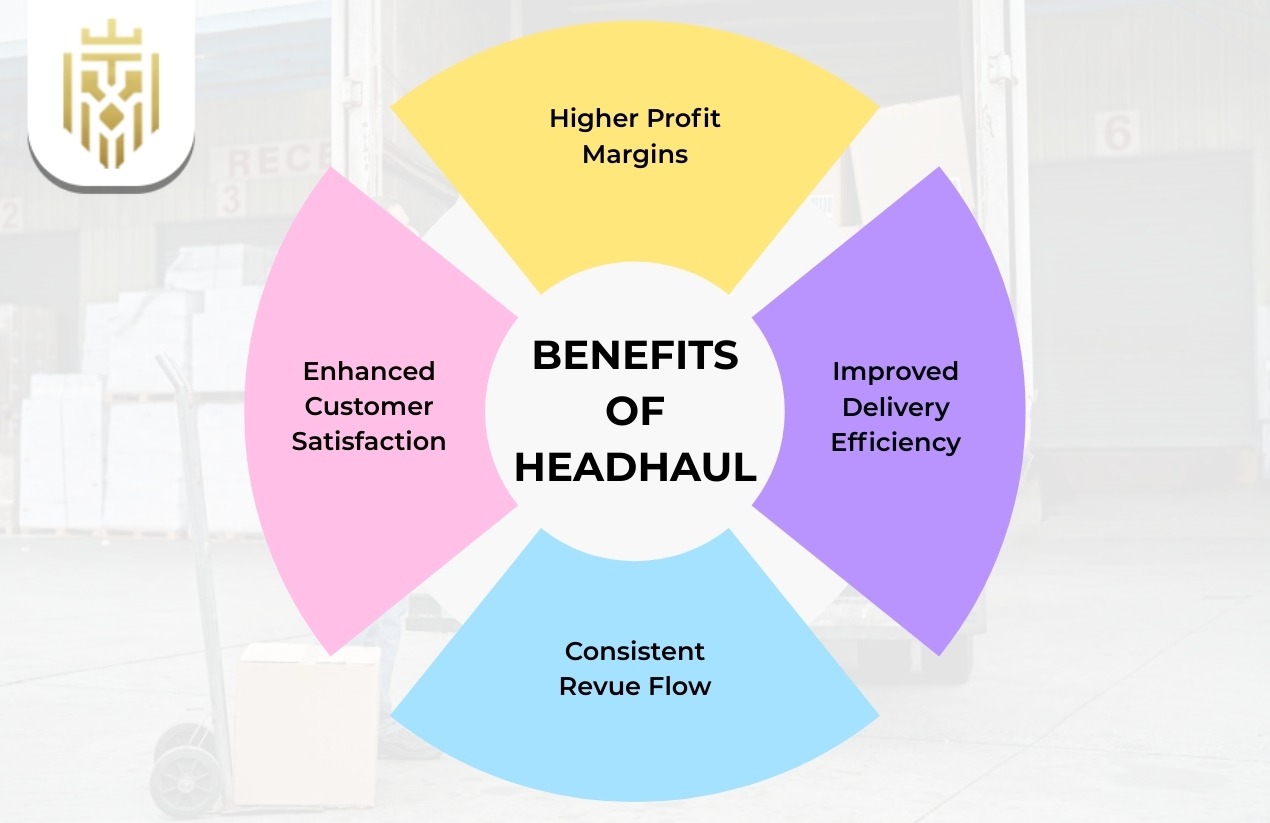

Benefits of Headhaul

The headhaul segment provides maximum truck utilisation as full loads are transported to high-demand destinations. It promotes profitability and lessens empty miles in the supply chain. Good headhaul and backhaul shipping coordination enhances the balance in logistics, providing easy freight movement and on-time delivery, which leads to the overall efficiency in the transport and improved carrier relations.

Higher Profit Margins

The better optimised headhaul freight movement provides greater returns through better utilisation of truckloads and minimising trips without loads. Better delivery coordination and strategic route planning enhance efficiency in transport and permit carriers to earn more revenue per trip and still practise cost-effective logistics management activities over the freight transport network.

Improved Delivery Efficiency

Headhaul shipping operations are focused on timely shipments and organisation of shipping routes and capacity management. By using real-time tracking and efficient route optimisation of headhaul, carriers minimise the delays, improve customer trust, and improve their supply chain performance by smoother freight transport and high rates of on-time deliveries.

Consistent Revue Flow

Optimisation of headhaul schedules also provides stable income streams through stable cargo demand. Carrier network collaboration and proactive route planning can enable logistics providers to stabilise the revenue cycles, reduce downtimes, and enhance financial predictability in dynamic freight transport systems and contemporary logistics management models.

Enhanced Customer Satisfaction

Efficacious headhaul planning results in a quicker and more reliable delivery. Combining logistics management tools and the optimisation of the headhaul routes, shippers achieve more reliability, less lead time, and client satisfaction, guaranteeing the high level of service provision throughout the supply chain processes and being able to control the costs and delivery accuracy at the same time.

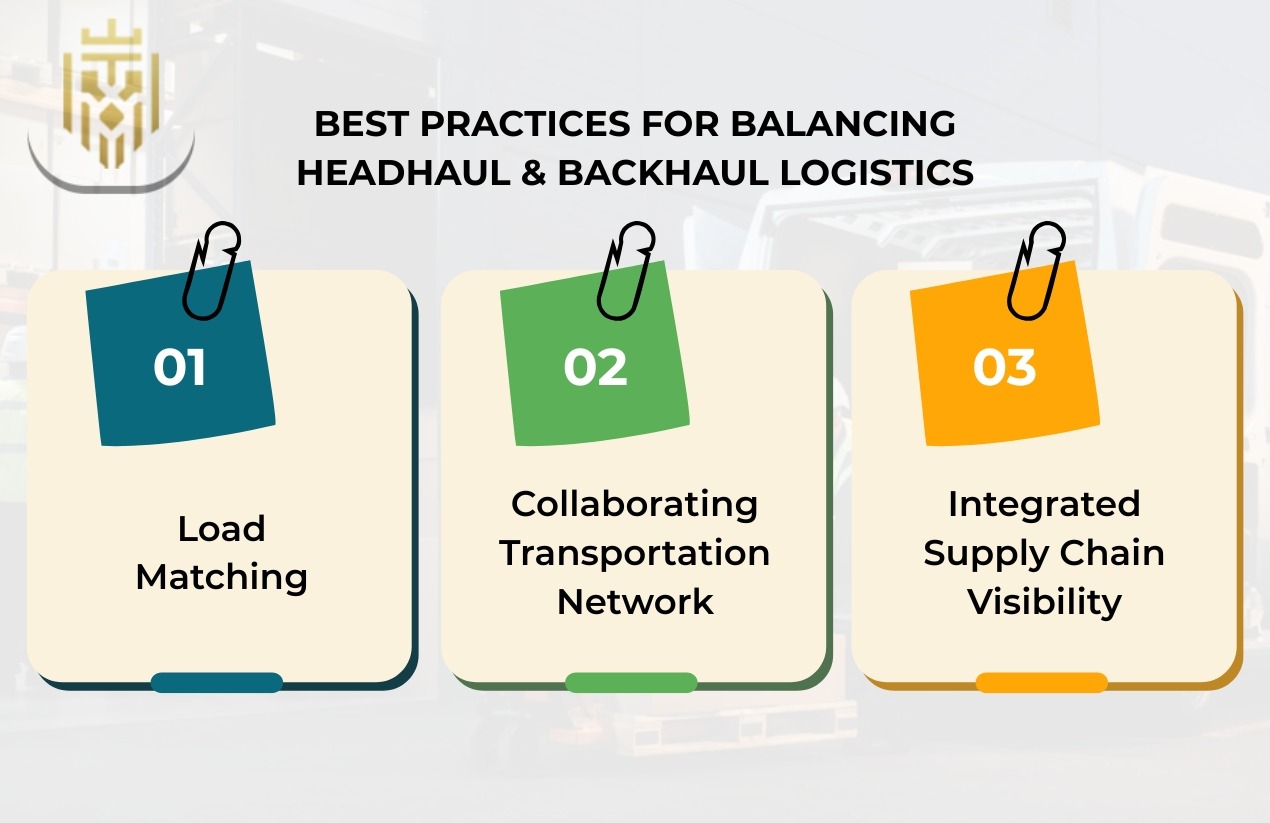

Best Practices for Balancing Headhaul & Backhaul Logistics

Proper balancing between headhaul and backhaul shipping reduces the number of miles that are empty and enhances transport efficiency. By combining smart scheduling, route synchronisation, and supply chain visibility systems, companies can coordinate the trips, which will lower costs and ensure the continuity of freight transport between destinations and return paths.

Load Matching

Proper load matching also means that vehicles do not transport empty cargo during both headhaul and backhaul transport activities. Through logistics management software, companies can maximise vehicle use, minimise fuel wastage and maximise supply chain efficiency by ensuring a coordinated shipment that reduces operation costs and increases delivery reliability.

Collaborating Transportation Network

An integrated carrier system encourages shipper cooperation, which facilitates the transportation of freight and facilitates headhaul and backhaul delivery. The integration of logistics management platforms leads to the creation of coordination where partners can share capacity, reduce idle assets and attain higher transport efficiency along regional and national routes.

Integrated Supply Chain Visibility

Incorporating supply chain visibility applications assists in real-time monitoring of headhaul and backhaul transportation processes. Greater transparency improves coordination and minimises delivery discrepancies, which leads to data-driven logistics management to add to the optimal route, better customer satisfaction, and quantifiable improvements in operational performance.

Challenges in Managing Headhaul and Backhaul Logistics

The headhaul and backhaul shipping may be a complex task because of the changes in the freight transport demand, imbalances in the routes, and variations in costs. To overcome these issues and maintain the optimal transport efficiency in the competitive logistics network, efficient logistics management and digital systems of route planning are necessary.

Rate Disparities

Inconsistency in prices between headhaul and backhaul transport produces an unbalanced profitability. With logistics management analytics, companies can make price modifications, enhance the synchronisation of the supply chain, and create plans that reach a cost equilibrium and deliver sustainable profitability in freight transport across different lanes.

Coordination Complexity

Headhaul and backhaul shipping management needs sophisticated coordination to eliminate empty miles and inefficiency. Integrated logistics management software and smart route planning tools facilitate the operations and align schedules, reduce disruptions across the supply chain, and encourage balanced and efficient transport management.

Uneven Freight Demands

The changing volumes of freight transport of goods between regions threaten the headhaul and backhaul logistics strategy. With demand forecasting and real-time route optimisation, carriers achieve balance, optimise utilisation, and ensure continuity in operations in a dynamic supply chain environment.

Regulatory Constraints

Backhaul in logistics may be limited on a regional basis depending on compliance, which influences delivery schedules and capacity scheduling. Effective freight carrier coordination, legal awareness and proper logistics management can minimise disruptions and compliance and keep supply chain operations and transport efficiency effective.

FAQs

1) What is the main goal of backhaul transport?

Backhaul transport is primarily aimed at minimising empty miles and maximising the truck utilisation and reducing the cost of transport through the transportation of return loads that have been carried following the primary headhaul delivery.

2) What industries use headhaul and backhaul logistics most often?

Retail, manufacturing, automotive, and e-commerce industries are some of the industries that require the use of headhaul and backhaul logistics to streamline freight movement, enhance route optimisation, and guarantee an uninterrupted flow of goods in the supply chain.

3) Is backhaul only related to trucking?

No, backhaul in logistics is applicable in the transport of freight by trucking, rail, air and sea. It concerns returning loaded vehicles or containers and reduces empty returns and enhances the overall transport efficiency.

4) How does technology help balance headhaul and backhaul operations?

Technology is used to optimise the path, track in real-time, and analyse logistics. These tools align headhaul and backhaul shipping, enhance visibility, and improve supply chain efficiency by reducing idle travel as well as minimising fuel usage.