What is Aggregate Planning in Supply Chain?

Aggregate planning in supply chain refers to creation, analysis and upkeep of a tentative, casual schedule of a preliminary, unrealistic schedule of the aggregate operations of an organization. It defines the best production rates, inventories and work force requirements on a medium term basis.

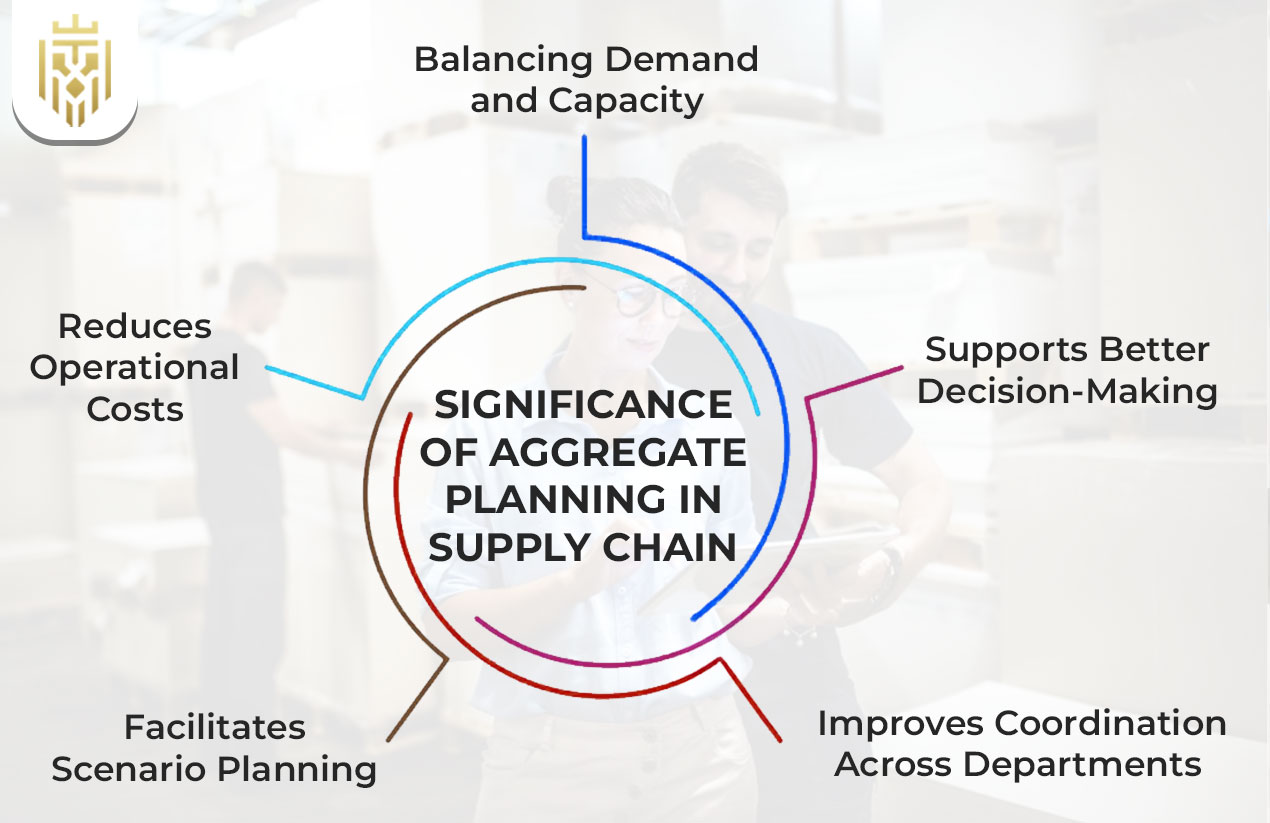

Significance of Aggregate Planning in Supply Chain

Importance of aggregate planning in supply chain can be attributed to the fact that aggregate planning is helpful in generating a good aggregate plan that guide resource utilization, production plans, and enhanced demand management that in effect increases the supply chain functions and hence customer satisfaction.

Balancing Demand and Capacity

Aggregate planning in supply chain management focuses on a balancing (or optimization) of demand and capacity. It makes sure that the production capabilities respond to the market demands, avoiding either excessive use of resources or their under use, which would affect the profitability.

Supports Better Decision-Making

Aggregate planning can be used to plan the operations of the supply chain, which provides managers with the needed critical information making superior decisions about the schedules of production plans, monetary activities, and labour coordination making them more responsive to change in the market.

Improves Coordination Across Departments

An effective aggregate production planning increases the cross-departmental collaboration across other departments e.g. operations, finance, and sales departments. This promotes enhanced communication, good use of resources and chain management procedures.

Facilitates Scenario Planning

The aggregate planning helps the organizations to simulate various situations of production. It helps to reveal the possible risks and opportunities so that to make the good decisions in the activity of supply chain management.

Reduces Operational Costs

Aggregate planning as part of supply chain can be used to cut down costs of operation through alignment of resources and production schedules as well as inventory. This will avoid excess production and unwarranted stocks as well as wastage of labour costs.

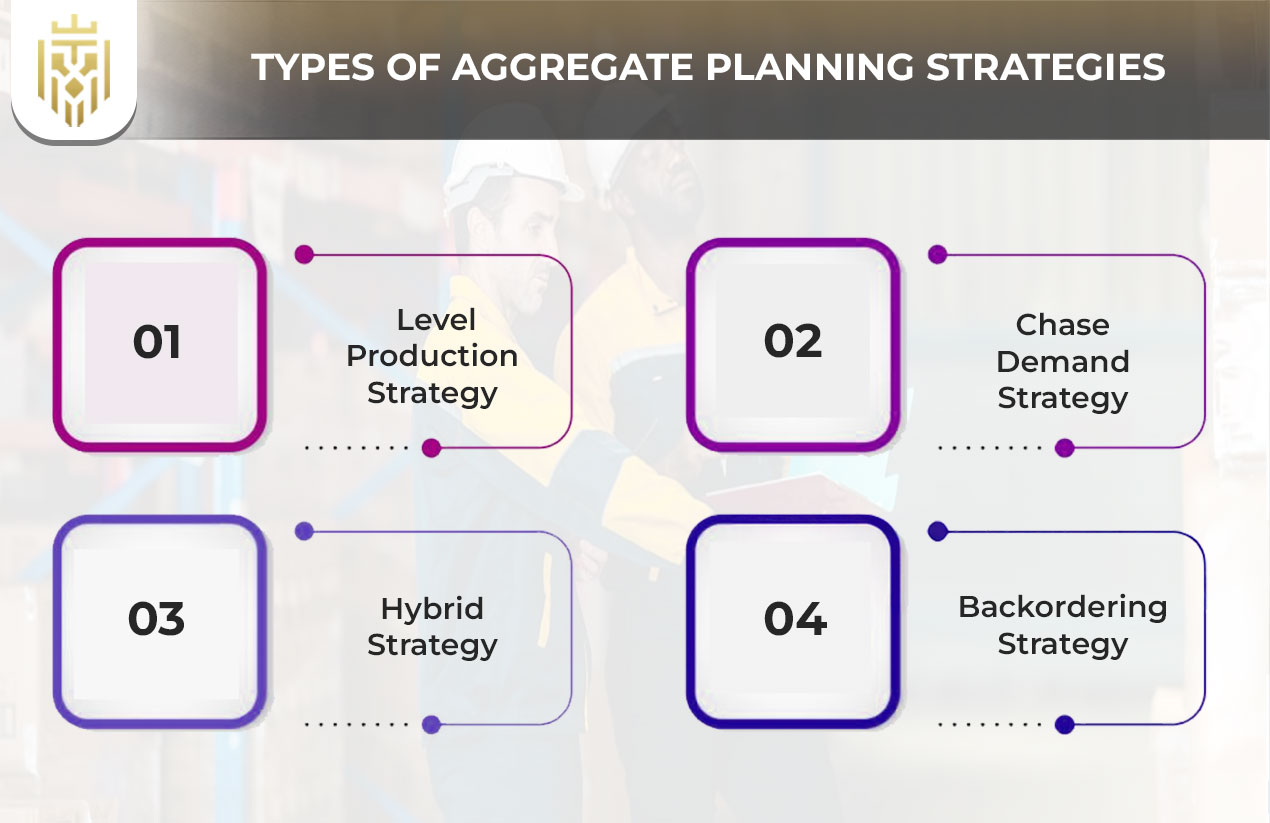

Types of Aggregate Planning Strategies

Major strategies of aggregate planning in supply chain management are Level Production Strategy, Chase Demand Strategy, Hybrid Strategy and Backordering Strategy which have got different approaches to settling the production output with the demand in the market.

Level Production Strategy

The strategy of level production ensures that the rate of production remains unchanged despite the fluctuations in the level of demand. This contributes towards stabilising the workforce requirement as well as easing the supply chain planning.

Chase Demand Strategy

The chase demand strategy increases or decreases production depending on the demand level. This works to reduce inventory levels, holding costs and means that supply is kept at very close levels to that required by the customer.

Hybrid Strategy

A hybrid strategy is an approach that integrates a level production and chase demand strategy. It aids in giving flexibility in production and an allocation of workforce in promoting a balance between efficiency and responsiveness in the supply chain management.

Backordering Strategy

Backordering strategy is used when the demand is higher than the production capacity of the firm, orders are entered with assurance that it will be delivered in the future. Although it can eliminate the short-term production pressure, it needs a meticulous aggregate planning to prevent customer dissatisfaction.

Factors Affecting Aggregate Planning in Supply Chain

The main factors which affect aggregate planning in supply chain include Demand Variability, Production Flexibility, Inventory Levels, Supply Chain Disruptions, and Cost Factors, which influence production decisions as well as management of resources and the overall performance of the supply chain.

Demand Variability

The change in customer demand has severe consequences on the aggregate plan. Proper forecasting is necessary to match between production and inventory with the demands of the market and the effectiveness of the supply chain.

Production Flexibility

Such a high level of flexibility in production allows business to adapt to changes in production in a short term, thereby improving planning supply chain activities. It assists in coping with the sudden fluctuations in demand and is less reliant on huge stores which are used as buffers.

Inventory Levels

Effective aggregate planning in supply chain involves essential ability to maintain optimal inventory levels. Effective inventory management eliminates out-of-stock and overstock situations, which facilitate an efficient production and order process.

Supply Chain Disruptions

Even the perfect aggregate planning cannot help in the supply chain management due to disruptions such as transport problems or non-performance of suppliers. It is necessary to reduce these effects through proactive risk management and a contingency plan.

Cost Factors

The decisions of aggregate planning are immensely affected by cost elements such as labour, materials and transportation. An effective strategy will enable a company to streamline costs without compromising quality of services within the supply chain.

FAQs

1) What is aggregate planning in the supply chain?

Aggregate planning in supply chain refers to creation, analysis and upkeep of a tentative, casual schedule of a preliminary, unrealistic schedule of the aggregate operations of an organization. It defines the best production rates, inventories and work force requirements on a medium term basis.

2) What are the Factors Affecting Aggregate Planning in Supply chain?

The main factors which affect aggregate planning in supply chain include Demand Variability, Production Flexibility, Inventory Levels, Supply Chain Disruptions, and Cost Factors, which influence production decisions as well as management of resources and the overall performance of the supply chain.

3) What are the Types of Aggregate Planning Strategies?

Major strategies of aggregate planning in supply chain management are Level Production Strategy, Chase Demand Strategy, Hybrid Strategy and Backordering Strategy which have got different approaches to settling the production output with the demand in the market.

4) What is the significance of aggregate planning in the supply chain?

Importance of aggregate planning in supply chain can be attributed to the fact that aggregate planning is helpful in generating a good aggregate plan that guide resource utilization, production plans, and enhanced demand management that in effect increases the supply chain functions and hence customer satisfaction.