What is A Backorder?

Backorder is the term used for an out-of-stock product that a business continues to sell and promise delivery as soon as inventory is replenished. This leaves the businesses to maintain order processing and keep customers until they are ready for the delivery. Knowing the backorder process and having the ability to take full advantage of it, enables companies to gain better supply chain visibility and achieve seamless order fulfilment and better stock management.

Why is Backordering Important?

Backordering keeps customers by letting them buy out of stock items and increases sales by capturing the demand during the stock-out. It helps in stock-control by preventing overstocking and helps in production planning. Not only does it alleviate supply chain visibility issues, it also improves customer loyalty and lowers competition by safeguarding orders even in inventory shortfall.

Reduces Competition

A backorder strategy can allow businesses to prioritise loyal customers in the event of stock shortage. Knowledge of backorder meaning enables business organisations to control products. By adopting the appropriate procedure of backorder as detailed, an effective implementation of backorders will be achieved, thereby reducing delays and keeping clients at ease.

Increased Sales

Backorders can be accepted to achieve increased sales by seizing the demand for products that are not available. Even with low stock levels, companies which know how to apply backorder in inventory management will be able to satisfy their customers and get higher revenue. This also enables the businesses to be aware of the new trends and respond by changing production.

Supply Chain Visibility

Monitoring backorders enhances visibility of backorders in supply chain management to monitor stock, supplier operations, and orders. Implementing the gathered knowledge of backorder definition will help to contain the delays. Firms that manage inventory backorders effectively are able to maximise on resources and minimise the occurrence of backorders in future.

Customer Retention

Managing backorders in a proper manner enhances customer retention as buyers will not be left without knowing about unavailable products. Companies that manage effectively their backorder procedure build loyalty and trust that leads to repeat buyers and good customer relationships in stock outages. Open communication fosters trust and enhances brand loyalty.

Production Planning

Backorders give information about the production planning and the alignment with the demand forecasting. Those firms that know how does backorder work are able to plan their manufactures well, prevent delays and put more resources into satisfying customer needs. This forward looking planning also eliminates bottlenecks and eases supply chain operations.

How Long Does A Backorder Take?

The time that a backorder takes can vary from 14 to 21 days depending on things like suppliers, manufacturers and shipping efficiency. For more unique and niche products the backorder fulfilment days could take up-to months, or in case large complex systems like aircrafts, the backorder fulfilment time stretches into years.

To maintain customer trust, order processing transparency and timelines have to be ensured. Businesses with good supply chain visibility can reduce delays and order fulfilment for better experiences for customers.

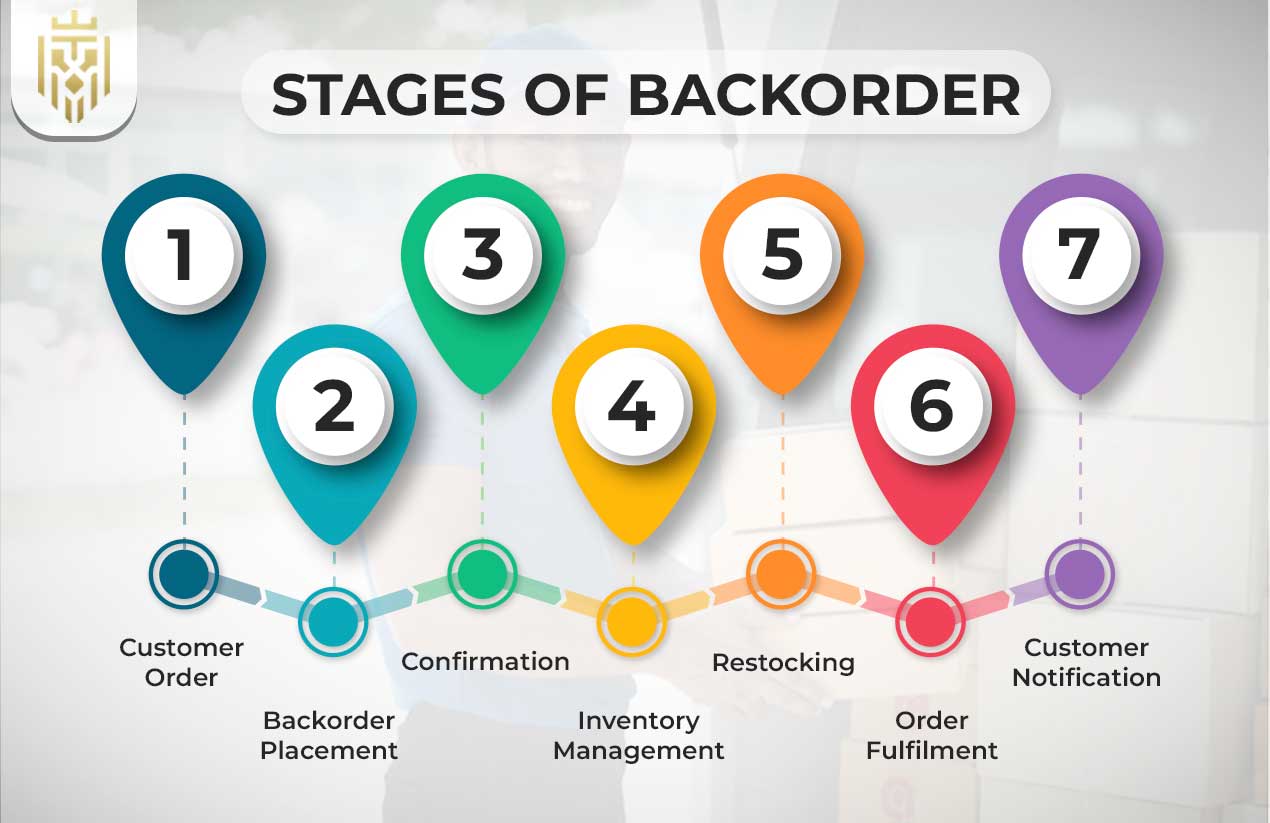

How does Backorder Work?

When customers order unavailable items, backorders start. These businesses confirm orders, manage inventory, replenish stock and fulfil orders. Timely order fulfilment and transparency, with efficient order processing and supply chain visibility, to maintain trust during delays.

Customer Order:

The backorder process is initiated by customers who place orders for items that are unavailable, and businesses capture demand. It guarantees order processing process without interruptions and equates stock control with customer’s requirements. Backorder meaning in inventory systems is important as it manages such orders effectively.

Backorder Placement:

Orders are accepted for out of stock products, and order fulfilment will occur once the inventory is replenished. It keeps customers engaged and solves the supply challenge. Placing correctly also ensures supply chain visibility and stops lost sales opportunities.

Confirmation:

Companies notify customers when they confirm backorders and give them timeframes of when they expect the product to arrive. Order processing is aided by clear communication and builds trust. Supply chain visibility is an essential part of transparent confirmations, which contributes to customer satisfaction.

Inventory Management:

Stock shortages are revealed through backorders that incite businesses to improve inventory tracking and forecasting. And an efficient stock control will enable smooth replenishment without any future shortages. Strong supply chain visibility helps minimize disruptions and ensures smooth operations during high demand periods.

Restocking:

To deal with backorders effectively, businesses reorder manufacturing or sourcing. Order processing is done properly to allow items to be met as quickly as possible. Restocking brings inventory levels in sync with supply chain visibility, shortening delivery time lines.

Order Fulfilment:

After restocking, businesses ship quality checked products, which completes the order fulfilment process. This step maintains customer’s trust and makes backorder resolution efficient. Supply chain visibility and operational efficiency are enhanced via proper coordination.

Customer Notification:

The backorder status is communicated to customers about the estimated date, whether they should wait or cancel. This means that there are continuous updates for order processing and transparency. Proactive communication improves supply chain visibility and customer satisfaction.

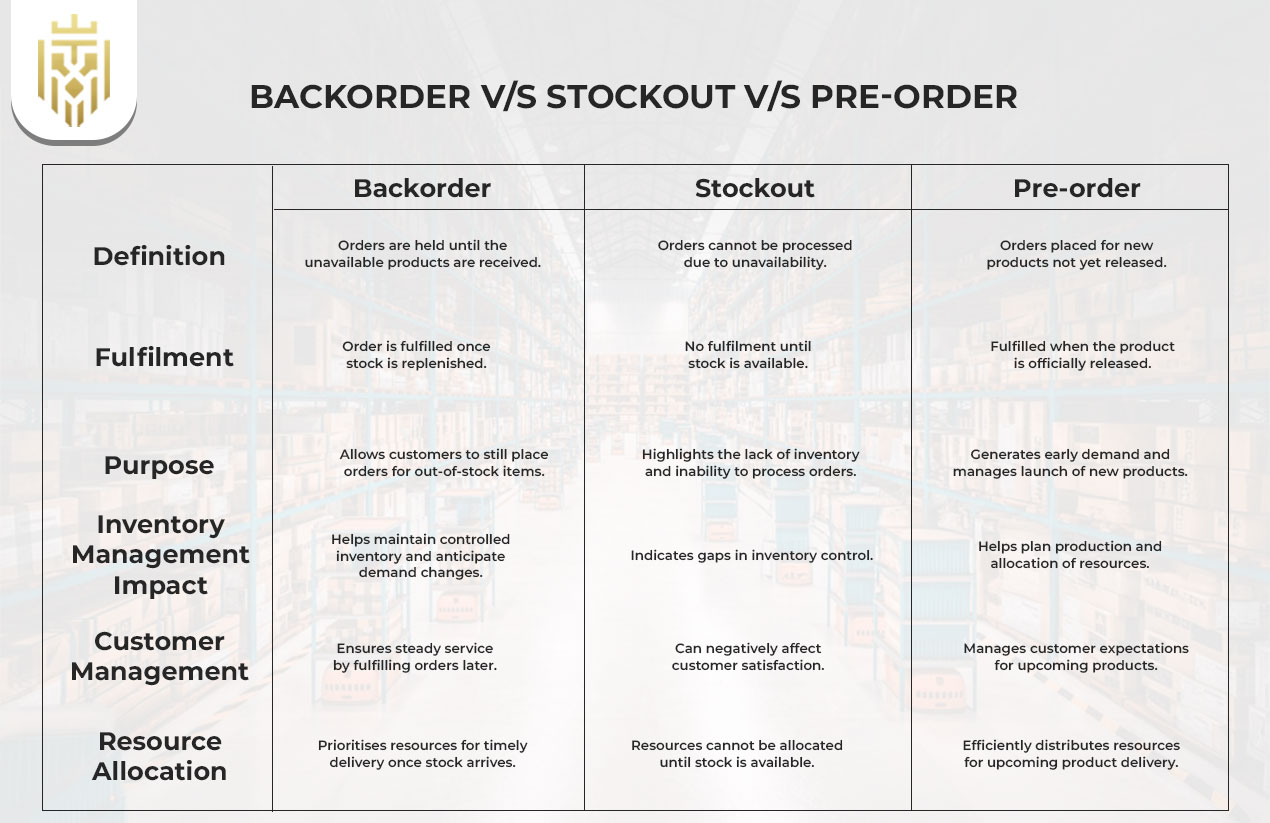

Difference Between Backorder & Stock out

The primary backorder vs stockout difference is in fulfilment. Backorders hold the orders until the unavailable products are received and stockouts do not allow processing. Knowing what each of these definitions implies enables businesses to keep the inventory controlled and to think ahead in terms of demand changes. The understanding of this can be used to introduce a company to improved inventory backorder management practises and a steady level of service.

Back Order vs Pre-order

A backorder vs pre order comparison indicates that backorders are used on products that are currently out of stock, whereas pre-orders are on new products. The knowledge of the backorder process explained and its proper application makes the customer management good. The companies are also able to distribute resources efficiently and prioritise the orders to ensure timely delivery of the backorders and pre-orders.

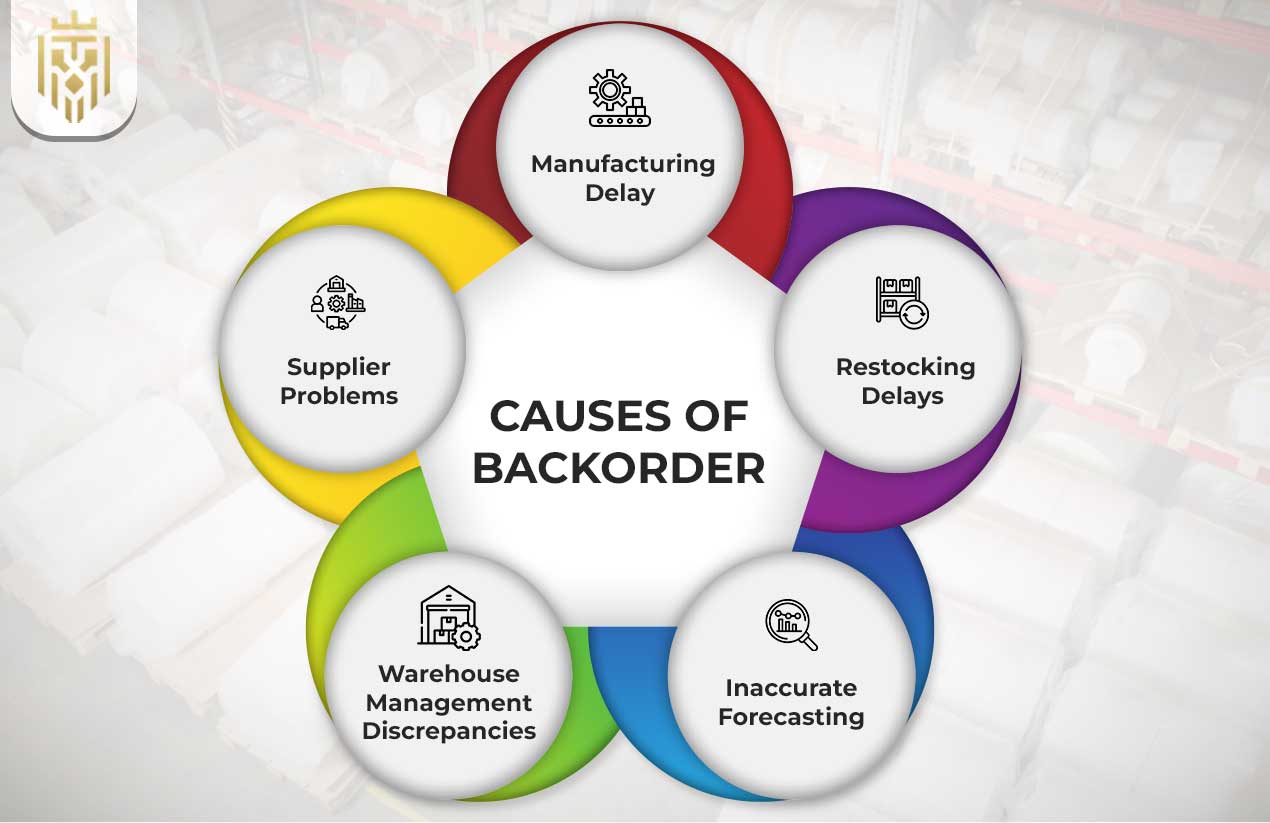

Causes of Backorder:

Manufacturing delays, inaccurate forecasting, supplier issues, and warehouse management errors are the causes of backorders. With improved stock control, visibility of the supply chain and proactive communication, these can be addressed and therefore order processing is smoother and there are fewer disruptions.

Manufacturing Delay:

This delay in production results in backorders caused by inventory shortages due to delays in order fulfilment. Supply chain visibility and communication can be improved, and there will be a mitigation of disruptions. Such delays negatively affect customer service and lower customer’s trust in order processing systems.

Restocking Delays:

Backorders are a result of both supplier inefficiencies and poor forecasting resulting in delayed restocking. Timely order fulfilment requires better supply chain visibility and better demand predictions. Then, these delays are addressed for the smoother stock control and satisfied customers.

Inaccurate Forecasting:

If insufficient inventory is maintained, then customer demand is underestimated and there are backorders. With accurate forecasting, stock control is improved and order delays prevented. Businesses that attain high supply chain visibility can predict demand better, and reduces backorder occurrences.

Warehouse Management Discrepancies:

Mismatches occur due to errors, theft, or poor inventory tracking and cause unexpected backorders. By improving warehouse practices, stock control and discrepancies will improve. Better supply chain visibility and faster order processing are ensured by efficient tracking.

Supplier Problems:

Backorders are created when production delays, material shortages, or shutdowns prevent order fulfilment. Supplier relationships and contingency plans need to be improved by business. Supply chain visibility should be strong enough so that stock is available and order processing is smooth even when disruptions occur.

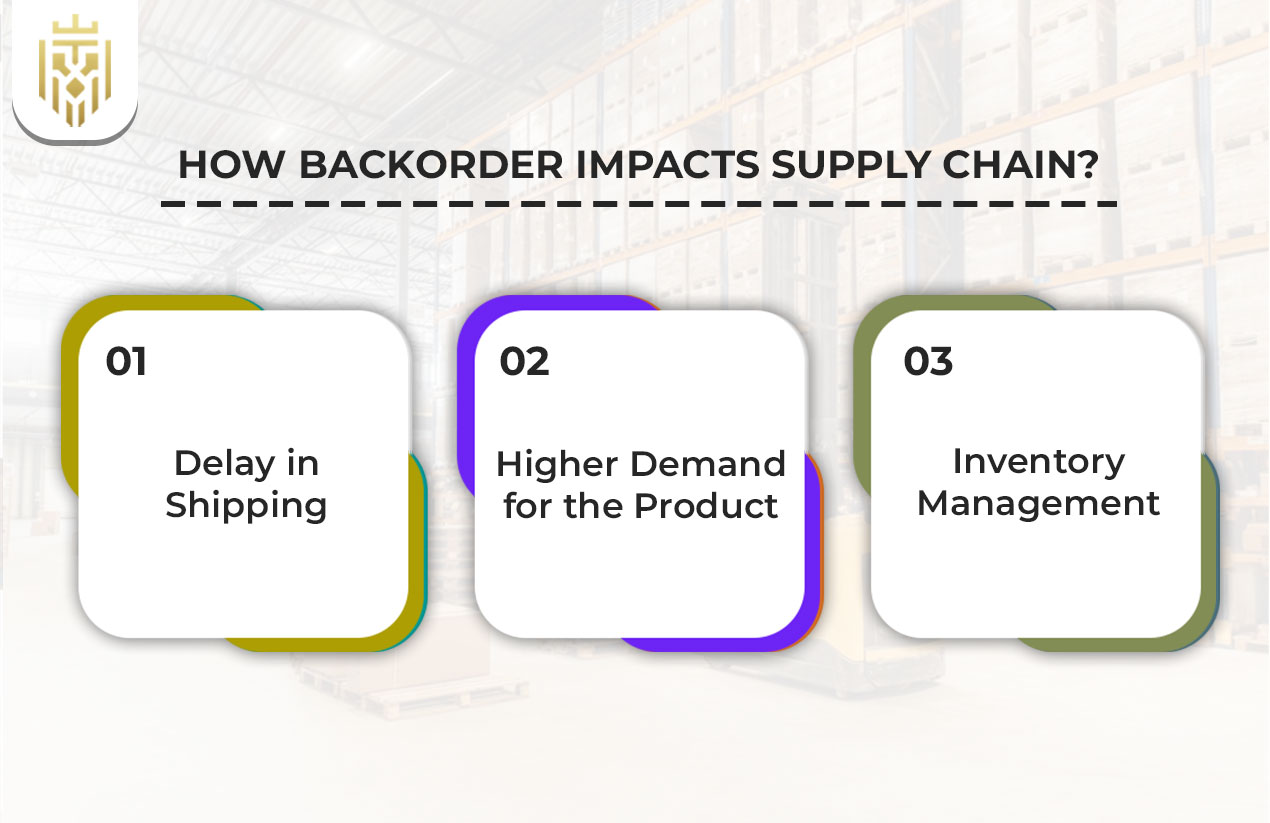

How Backorder Impacts Supply Chain?

Backorder in inventory management and other supply chain areas in the supply chain create bottlenecks and lost deliveries. To ensure the smooth operation of businesses, businesses need to reduce backorders with forecasting. Knowing the effect on suppliers, production schedules, and logistics enables organisations to utilise strategies that ensure the responsiveness and reliability of the supply chains.

Delay in Shipping

Backorders count as one of the main causes for delays in shipping is frequently caused by backorders. Inventory backorder management assists businesses to give importance on order and stock management. Reduction of shipping time also enhances customer satisfaction and operational efficiency along the supply chain.

Higher Demand for the Product

Demand items can be on back order, which is an indication of supply constraints. Monitoring and controlling stock can enable companies to work on improving backorder fulfilment, as it allows tracking of trends. Proper demand forecasting will ensure that quality products are in stock and loss of sales is minimised.

Inventory Management

There is efficient inventory management which will improve backorder fulfilment through balancing stock and customer demands. Companies deploying the demand forecasting process can streamline their products and have control over orders. There is effective inventory back-orders management that helps avoid stock out and facilitates the operations of the supply chain.

Challenges in Accepting Backorder

The drawbacks of accepting the backorders are delays and customer dissatisfaction. Learning about the causes of backorder enables the companies to deal with inventory. These obstacles can be properly resolved to avert a more organised order fulfilment and customer confidence.

Increases Service Demands

Backorders drive up service demands, with customer care responding to queries. Those companies which learn to cope with the backorder processes successfully can streamline the operations. The automated systems and trained employees minimise work load and at the same time ensure that customers are attended to in time.

High Risk of Order Cancellation

Prolonged backorders increase the risk of order cancellation. Understanding how long does backorder take would enable businesses to create attainable schedules. Avoided cancellations and loss of customer loyalty can be reduced by offering alternatives or incentives in case of delay.

Managing Backorders Effectively

Understanding effective backorder process explained well guarantees the businesses to have the capability to deal successfully with product shortages and serve their customer orders. Effective backorder management practises enhance the efficiency of operations and reinforce the performance of the supply chain.

Adopting Inventory Management Systems

Installation of inventory management systems enhances the visibility of the backorders and stock levels. The companies that support process explained are efficient in processing orders. This minimises the mistakes and delays in the supply of products.

Accurate Demand Forecasting

Proper demand forecast predicts future demand of products and minimises backorders. Forecasting enables companies to optimise stocks and set up production by reducing backorders. Forecasting can also be used to maintain the level of services and enhance customer satisfaction.

Lead Time Optimisation

Optimisation of lead times reduces lead time delays with regards to backorders. Knowledge of backorder in supply chain assists in synchronisation of production, shipping, and stock replenishment. The effective lead time management makes delivery on time and minimises operational interruptions.

Customer Communication

The backorders increase trust through proper customer communication. Loyalty can be sustained by companies who enhance their backorder fulfilment by sharing timelines with the correct accuracy. Along with regular updates, they help to cope with expectations and avoid cancellations.

Buffer Stock

A buffer stock eliminates the backorder risks in times of high demand. The use of backorder in inventory management will make products available when they are needed. Buffer stock is used to assist businesses in dealing with spikes in demand and avoid supply hiccups.

Supplier Relationships

Good rapport with suppliers means that there is a timely supply to reduce backorders. Businesses, which know how to liaise with suppliers, do not run out of stock. The partnership with trusted suppliers enhances the performance of the supply chain and contributes to the steady product supply.

FAQs

-

What is a backorder?

A backorder is an out-of-stock product the business promises to deliver once the inventory is replenished. It enables order processing, order fulfilment and supply chain visibility, the customer engagement.

-

Why is back-ordering important?

Backordering will eliminate loss sales, improve stock control, and will keep customers by allowing purchases even when there are stockouts. It enhances supply chain visibility, mitigates disruptions, improves order processing, strengthens customer loyalty and helps you minimize competitive risks.

-

How does Back Order Work?

When customers order unavailable items, backorders start. These businesses confirm orders, manage inventory, replenish stock and fulfil orders. Timely order fulfilment and transparency, with efficient order processing and supply chain visibility, to maintain trust during delays.

-

How long does backorder take?

It will arrive 14–21 days after the backorder depending on suppliers and manufacturers. The businesses that have excellent supply chain visibility and good order processing capabilities can reduce the delivery delays and deliver the order timely and the customer satisfaction is much higher.