What Is a Distribution Centre?

A distribution centre is a facility where products are received, stored, processed, and then shipped to customers or retail stores. It is essential in supply chain management, as it is the hub in the maintenance of an efficient flow of goods in different locations.

Why Does a Distribution Centre Matter?

Knowing what a distribution centre is helps understand that it is strategically important to implement timely deliveries and to control costs. It offers flexibility to cater to the needs of the consumers, lowers the waste of storage space, and can scale in the long-term operations of the chain management business.

Enables Fast Order Fulfilment

Distribution centres push faster order processing since they enable the stocking of goods near target markets. This greatly increases the speed at which it gets fulfilled and also allows companies to provide same-day or next-day delivery, particularly when combined with a sophisticated fulfilment centre system.

Supports Scalable Operations

Flexible storage, labour, and shipping space are provided by distribution centres as business demand increases. Firms can flexibly expand or reduce their output depending on their volume so that their supply chain can be fast, lean, and in a position to handle seasonal bursts or growth strategies.

Reduces Transportation Costs

Companies position their distribution centres strategically close to the customers, minimising the last-mile deliveries. This streamlines the transportation, reduces the transport fuel expenditure, and shortens the delivery period, and the distribution centre is a major cost-saving ingredient in effective supply chain management.

Strengthens Inventory Management

An optimally managed distribution centre provides the real-life picture of the inventory levels that reduce cases of stockouts and overstocking. It also assists businesses in having a good level of stock, as well as enhancing accuracy, which plays a pivotal role in ensuring consistency in the entire ecosystem of the chain management.

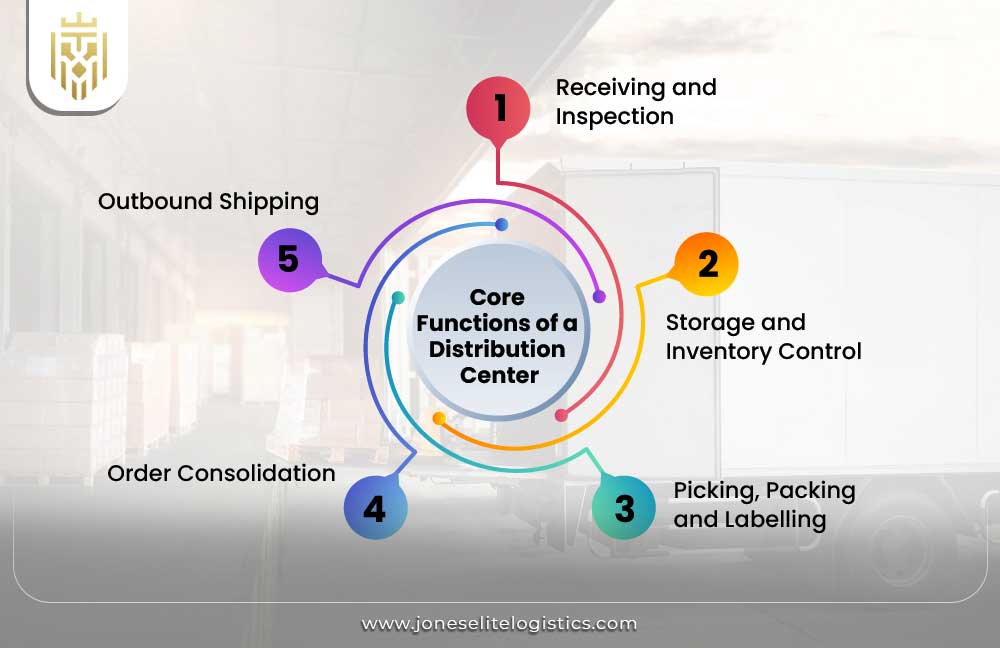

Core Functions of a Distribution Centre

The main activities of a distribution centre are receiving goods, examining goods, storing goods, picking, packing, and dispatching goods. They are fundamental in supporting customer expectations, and these activities are the basis of contemporary distribution centres, which are in the supply chain.

Receiving and Inspection

Goods inbound are accepted and thoroughly checked for quality and accuracy. This step eliminates the chances of errors and ensures the correct inventory that can be sold in the system. Fully functional receiving operations reduce delays, and they are crucial to the successful functioning of distribution centres in a variety of product categories.

Storage and Inventory Control

In the distribution centre, the products are categorised and stored systematically in order to be able to retrieve them quickly. Inventory movement and locations are tracked with inventory control systems that minimise errors. Such systems also improve the accuracy and reliability of the supply chain management in its various channels.

Picking, Packing, and Labelling

After receiving an order, the picking, packing, and labelling of items are done to load them for shipment. Automation in the distribution centres increases accuracy and shortens the fulfilment time. This guarantees the provision of correct and undamaged products to the customers, hence increasing satisfaction and efficiencies in its operations.

Order Consolidation

Order consolidation applies in distribution centre activities where the different items in varied zones get consolidated before final shipment. It reduces split shipments, reduces shipping costs, and enhances customer experience, particularly when operating complex fulfilment centre networks that generate many e-commerce orders.

Outbound Shipping

Optimised routes of transport are used to deliver goods to retailers and end customers. This step connects the last-mile delivery to the distribution centre to guarantee the delivery on time. Proper documentation and route planning are important in this case to facilitate smooth performance in the chain management.

Types of Distribution Centres

Different distribution facilities exist, such as centralised distribution centres, regional centres, and 3PL-controlled distribution centres. By being aware of the distinction between a warehouse and a distribution centre, companies opt to use the correct model depending on the needed supply chain attributes, including speed, flexibility, or volume.

Centralised Distribution Centres

A central distribution centre covers a large geographical space based on one point. It makes the inventory management much easier and operationally less complex, particularly for businesses with few SKUs or high regional demand. Nevertheless, it can imply increased transportation expenditures regarding distant travel.

Regional Distribution Centres

Regional distribution centres cover a particular area, which makes it easier to fulfil an order. Such centres help in cutting delivery time and are best suited in places where demand is high. The arrangement also equalises stock between regions and enhances adaptiveness in dynamic supply chain management setups.

Cross-Docking Facilities

Cross-docking eliminates the long-term storage phase as goods are transferred (directly) between incoming and outgoing vehicles. These distribution outlets reduce handling and enhance efficiency, especially in handling perishables. In chain management systems, this model greatly reduces the lead times and the costs of storing packets.

Third-Party Logistics (3PL) Distribution Centres

The 3PL distribution centres are operated by third-party providers who provide warehousing, order processing, and transportation. The centres are an advantage to companies that do not have infrastructure or scale. By contracting a 3PL, a business can concentrate on its core business, as well as improve its supply chain.

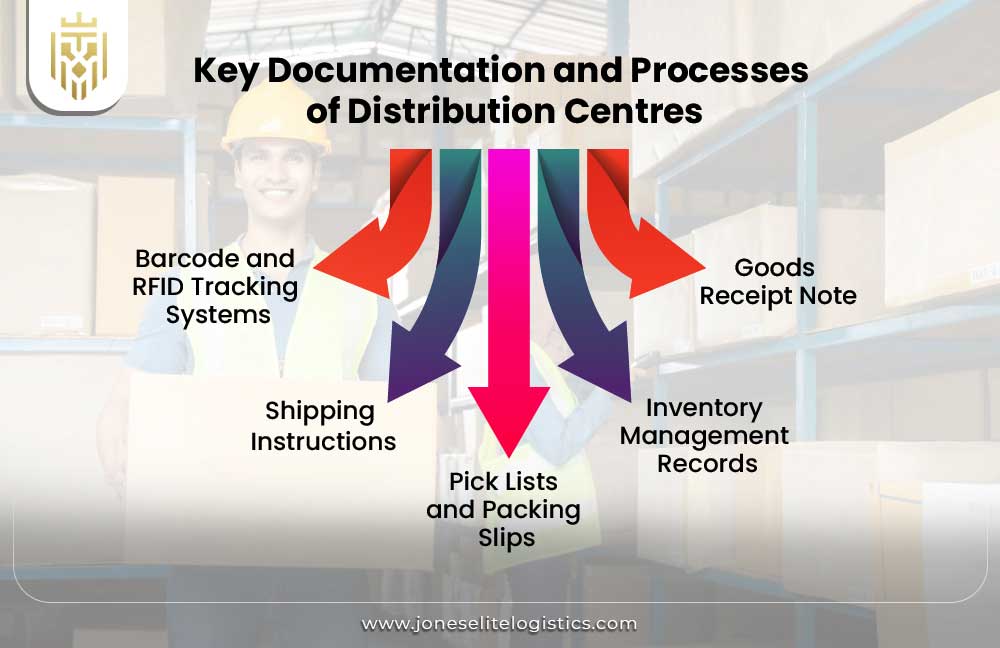

Key Documentation and Processes

There is no transparency and accuracy in a distribution centre without proper documentation. Compliance and minimisation of disputes and efficiency in the supply chain across all fulfilment levels are supported by essential paperwork and systems, such as shipping notes, inventory records, and tracking.

Goods Receipt Note

The Goods Receipt Note is an acknowledgement of the incoming stock delivery and inspection. It acts as legal documentation of received inventory in the distribution centre. This document is fundamental in resolving vendor disputes and verifying product quantities to get an accounting and audit of the same.

Inventory Management Records

These documents allow for monitoring the quantity, location, and movement of the products inside the distribution centre. They play a vital role in real-time viewing, restocking, and the prevention of stock mismatch. Supply chain management is also improved through effective tracking of inventory and reduced interference with distribution processes.

Pick Lists and Packing Slips

Staff are directed on what to pick up using the pick lists, and the accuracy of the order is checked using the packing slips. They enhance speed and precision in the fulfilment activities in conjunction, and thus, such documents are essential in both the fulfilment centre and the traditional distribution centre.

Shipping Instructions

Shipping directions include how the item should be delivered, what company to use, and any handling needed. In the outbound phase of a distribution centre, they are essential in coordinating the chain of all partners involved in logistics to facilitate an easy flow of goods in the entire supply chain network.

Barcode and RFID Tracking Systems

Barcode and RFID tracking systems automate product identification and transportation. In a distribution centre, they allow real-time inventory changes, minimise human error, and improve throughput. They are also becoming crucial in the contemporary fulfilment centre and chain management systems.

Common Challenges & Smart Solutions

Although distribution centres are desirable, they are associated with such drawbacks as inventory mistakes, workforce crunch, and downtime. Intelligent solutions such as automation, improved training, and real-time analytics guarantee efficient operation and solid performance in the present competitive supply chain environment.

Inventory Inaccuracy

Stock-taking errors may interfere with the fulfilment of orders and the satisfaction of customers. A distribution centre has to utilise frequent audits, WMS tools, and RFID to ensure proper inventory. The practices prevent wastage and returns in the supply chain.

Delayed Order Processing

Poor order management hurts promises of delivery. The process of picking and packing at the distribution centre is automated, and this saves a lot of time. ERP integration prevents bottlenecks in workflow processes, and it increases responsiveness to high-demand fulfilment centre settings.

Space Utilisation Constraints

Lack of space does not facilitate productivity. Dynamic slotting, vertical storage, and rack layout optimisation are some of the ways that will enable a distribution centre to maximise space usage. The effective usage helps to avoid overloading and accelerate the work process in the wider context of supply chain management.

Labour Shortages

The lack of skilled labour may postpone things. Automation, work training, and elastic staffing plans can address this problem in distribution centres. Using robotics is also reliable and curbs any form of error due to human beings in handling critical tasks in fulfilment centres.

Equipment Downtime

The failure of material handling equipment leads to a delay. Routine checkups and expenditure on advanced equipment minimise such upheavals. The importance of being able to keep the uptime in a distribution centre is significant to keep the flow in the connected supply chain network running smoothly.

Best Practices for Efficient Distribution Centre Operations

Embracing the best practices enhances accuracy and velocity in the distribution centres. The methods, such as real-time monitoring, throughput arrangements, and employee training, make operations efficient. These are practices that are significant, in particular when considering the distinction between the warehouse and distribution centre functions.

Implement Warehouse Management Systems (WMS)

A WMS increases visibility of the inventory, orders, and operations in real time. It enhances efficiency and decreases human labour within a distribution facility. Such integration of WMS is needed to enhance the service levels and achieve a performance integration with the performance targets of an entire supply chain.

Optimise Storage Layouts

Picking is accelerated by good storage design and cuts down travel time. The use of zoning, labelling, and vertical racking enhances the flow of orders in the distribution centre. The layout plans minimise congestion and maximise throughput in the small and large fulfilment centres as well.

Train and Upskill Staff

Quality training of the staff guarantees workflow, safety, and minimised mistakes. On-the-job training within a distribution centre is used to ensure that workers can keep up with technology and shifts to guarantee efficiency regarding the changing needs, which will improve overall supply chain management.

Regularly Audit Inventory

Planned audits limit the difference and enhance the level of accuracy of stocks. A distribution centre that employs either a cycle counting or a complete inventory check can identify troubles promptly. Such a practice is essential to ensure consistency and transparency across the larger ecosystem of chain management.

Integrate Real-Time Data Monitoring

Monitoring systems are utilised to trace the status of orders, the condition of equipment, and the productivity of labour in real time. With this information, there is the capacity to make proactive decisions that minimise the amount of downtime. In-time control is critical to any distribution centre whose goal is to improve performance within its supply chain activities.

Role of Distribution Centres in Supply Chain Success

The centre of modern logistics is the distribution centres. They forge a link between suppliers and consumers, making them more efficient and agile. The delivery speed, accuracy, and cost are all key foundation stones of effective supply chain management, and their performance is directly influenced by these factors.

Bridge Between Production and Customers

A distribution centre provides a connection between manufacturers and end-users. It will make goods available where and when they are required, and this will enhance customer satisfaction. This is a crucially important connection in the supply chain that enhances efficiency and responsiveness within various distribution patterns.

Enable Omnichannel Fulfilment

Due to the emergence of the e-commerce market, distribution centres are supposed to sustain both online and offline mediums. The ability to provide omnichannel fulfilment creates a uniform customer experience regardless of how they made the purchases, and fulfilment centres are invaluable parts of retail and hybrid supply chain architectures.

Improve Lead Times and Customer Satisfaction

Lead times are shortened to a great extent through quicker processing and delivery at the distribution centres. This responsiveness increases customer satisfaction and repeat purchases. Companies that are innovative in this regard tend to obtain a start-up advantage in the strained chain administration setting.

Lower Total Logistics Costs

Costs of handling, storage, and shipping are reduced by centralising the operations in a distribution centre. Lower logistics costs are also achieved through efficient routing, minimisation of errors, and streamlining labour, which would make the profitability of the whole supply chain management process great.

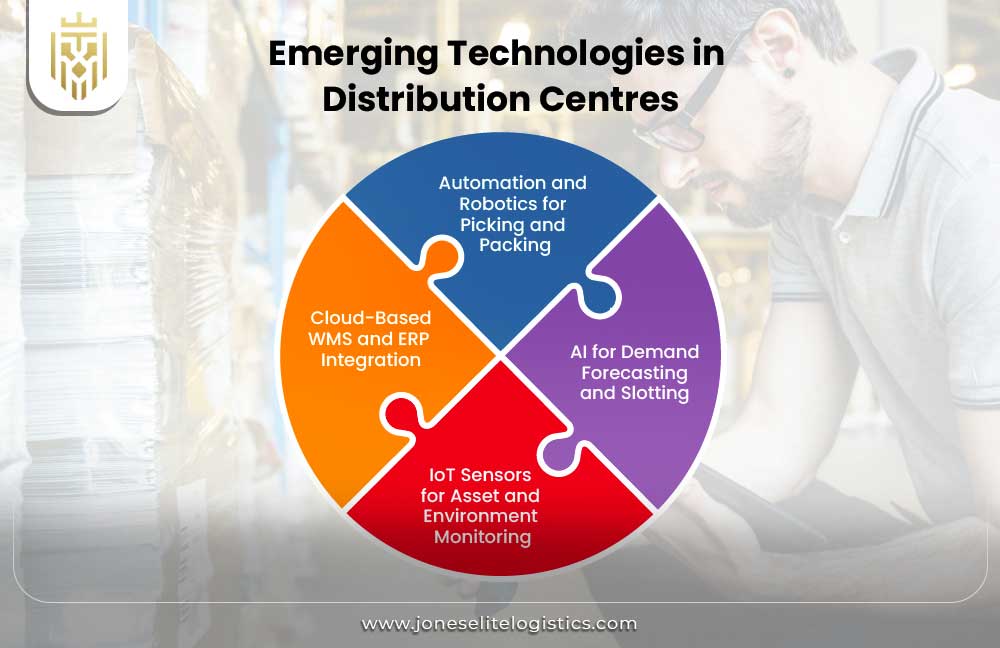

Emerging Technologies in Distribution Centres

New distribution systems are revolutionising distribution centres. Speed, accuracy, and decision-making are enhanced through automation, AI, IoT, and cloud systems. Such innovations play a critical role in redefining the efficiency standards in traditional and fulfilment centre logistical environments.

Automation and Robotics for Picking and Packing

Robotics helps in the automation of repetitive work, such as picking, packing, and sorting. They are also faster and lower the instances of errors when used in distribution centres. Such systems are critical to operations that handle high volumes of activities, ensuring any scaling by businesses does not diminish customer expectations.

AI for Demand Forecasting and Slotting

The use of artificial intelligence implements optimisation of product placement, as well as product placement forecasts. AI enhances slotting in a distribution centre, which minimises travel time and the availability of stock. Such advantages correspond to improved decision-making in the sophisticated chain management environment.

IoT Sensors for Asset and Environment Monitoring

The IoT sensors monitor the temperature conditions, humidity, and equipment status in real time. They warn managers about the possible problems at a distribution centre and help make immediate fixes and minimise spoilage or destruction, which is particularly relevant in the supply chain areas of food and pharma.

Cloud-Based WMS and ERP Integration

The cloud system enables the ability to access data easily between departments and locations. When combined with WMS and ERP, they enhance distribution centres in terms of coordination and decision-making, which enables consistent performance in the current operations of supply chain management.

FAQs

1) What is the difference between a warehouse and a distribution centre?

A warehouse is designed to hold goods over a long period of time, whereas a distribution centre has a high priority in placing orders, shipping, and rotating inventories in real-time demand and providing quicker delivery in the supply chain.

2) How do distribution centres affect delivery time?

Distribution centres help in shortening the delivery time, as the merchandise is stocked closer to the consumers, so that processing and shipping of orders can be done without delays. Such closeness reduces lead times and also boosts supply chain responsiveness at the regional level.

3) What technologies are used in modern distribution centres?

To enhance efficiency, error-free operation, and scalability during complicated operations of supply chains, modern distribution centres are adopting automation, robotics, IoT sensors, artificial intelligence to forecast, and cloud-based systems for their warehouse management system and enterprise resource planning software.

4) What industries use distribution centres most frequently?

Distribution centres are particularly important in the retail, e-commerce, pharmaceutical, consumer goods, and electronics industries, where they can process a large order volume within the supply chain to keep track of inventory and distribute timely supplies.

5) Can a distribution centre be managed in-house, or should it be outsourced?

Depending on the size and resources of a business, as well as their priorities in chain management, a distribution centre can be professionally handled in-house to control it or outsourced in order to scale these areas of expertise to 3PL providers.