Understanding Cost Structure

A business’s cost structures define how different expenses contribute to total operations. In the supply chain, they influence profitability, decision-making, and supply chain efficiency. Understanding cost categories like procurement cost, inventory cost, and logistics cost supports effective budgeting and long-term strategic cost management across the entire network.

What is Cost Structure in Supply Chain?

Cost structure in the supply chain is the summation of the costs that are needed to run the procurement, production, storage, and distribution. It plays a vital role in supply chain optimisation, identifying major supply chain cost drivers, and ensuring sustainable operations through cost reduction strategies and data-driven value chain analysis.

Fixed Costs

Fixed costs in the end-to-end supply chain remain stable regardless of output levels, including rent, equipment, and salaries. They form a foundation for working capital management, influencing financial planning and helping organisations control overhead costs and improve long-term supply chain efficiency and predictability.

Variable Costs

Variable costs vary as production and distribution activities vary. These are the cost of transportation, handling charges and freight expenses. Monitoring these elements through supply chain cost analysis ensures better cost structures, supports strategic cost management, and enhances supply chain optimisation by aligning expenditure with demand variations.

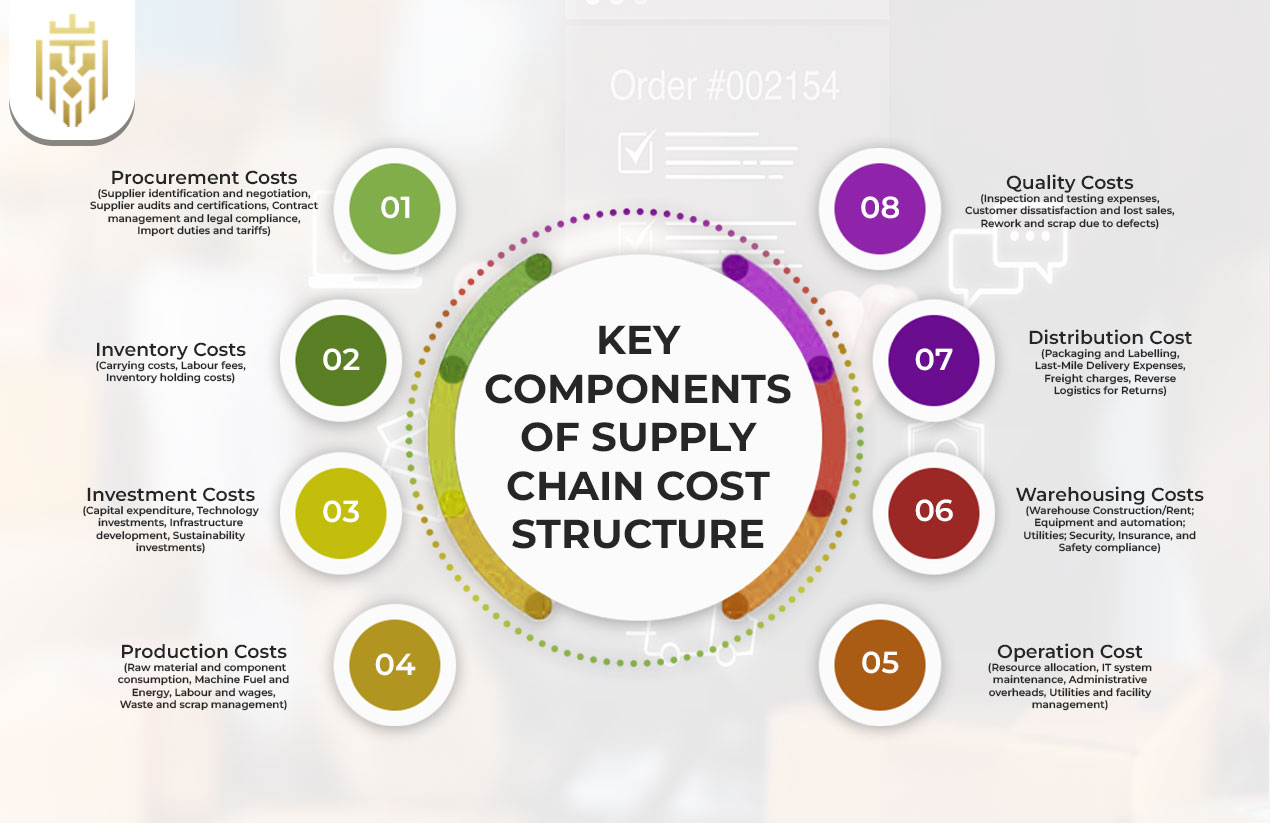

Key Components of Supply Chain Cost Structure

The main components of a supply chain cost structure include procurement costs, inventory costs, and production costs. Analysing each helps uncover supply chain cost drivers, optimise spending, and implement collaborative cost reduction methods for improved supply chain efficiency and cost visibility.

Procurement Costs

Procurement costs cover expenses from supplier sourcing to delivery. Efficient procurement process optimisation and a clear procurement and sourcing strategy minimise operating expenses, improve vendor relationships, and promote value chain analysis, driving cost reduction strategies and stronger overall supply chain optimisation.

Supplier Identification and Negotiation

Identifying reliable suppliers and conducting fair negotiations helps reduce procurement cost and logistics cost. A robust procurement and sourcing strategy ensures competitive pricing, strengthens supply resilience, and supports strategic cost management across the end-to-end supply chain.

Supplier Audits and Certifications

Regular supplier audits enhance quality control, compliance, and supply chain efficiency. They eliminate expensive downtime, minimize the operating cost and promote the cost reduction among the suppliers through the maintenance of the industry standard and sustainability levels.

Contract Management and Legal Compliance

Management of the contract reduces overhead cost and ensures compliance with legal requirements. Streamlined documentation and clear terms strengthen supplier relationships and reduce procurement cost, supporting efficient working capital management within the supply chain.

Import Duties and Tariffs

Import duties and tariffs directly affect total procurement cost and distribution cost. The planning of strategies regarding the regulations assists companies to regulate the freight prices and enhance the cost analysis of supply chains, which eventually optimises the global sourcing decision.

Inventory Costs

Inventory costs cover expenses for storing, managing, and maintaining stock levels. Tracking these through warehouse operations and supply chain cost analysis helps minimize warehousing expense, control inventory holding cost, and strengthen overall supply chain efficiency and responsiveness.

Carrying Costs

The carrying costs consist of the storage, insurance and the costs of depreciation of unsold stock. Managing these costs improves working capital management, enhances inventory system control, and supports effective cost reduction strategies across the supply chain.

Labour Fees

Labour charges are associated with manpower expenses on inventory management and warehousing. Controlling them helps balance operating expense, improve supply chain optimisation, and ensure sustainable resource utilisation within overall cost structures.

Inventory Holding Cost

Inventory holding cost represents a major portion of total inventory cost, covering storage, obsolescence, and insurance. Regular monitoring supports strategic cost management, efficient stock management, and better supply chain cost analysis.

Investment Costs

On costs of investment, there are capital expenditures on technology, infrastructure, and sustainability. Proper analysis of these supply chain cost drivers ensures high supply chain efficiency and supports strategic cost management for long-term growth.

Capital Expenditure

The capital expenditure includes money on equipment, facilities, or technology enhancement. It influences working capital management, operation costs and long-term optimisation of the supply chain so that companies get to stay competitive as they deal with the future stability of production costs.

Technology Investments

Investing in automation tools and software supports supply chain optimisation and enhances cost reduction strategies. Smart systems reduce operating expenses and strengthen value chain analysis, improving decision-making efficiency.

Infrastructure Development

Construction of efficient warehouses and distribution centres influences warehousing costs and transportation costs. These investments improve supply chain efficiency by ensuring smooth material flow and better inventory cost control.

Sustainability Investments

Sustainability investments help reduce energy conzsumption and logistics cost, aligning business goals with eco-friendly supply chain cost drivers. These initiatives promote long-term strategic cost management and brand reputation.

Production Costs

The production costs include all expenditures on buying raw materials for the manufacturing. Monitoring production cost ensures efficient cost structures, minimises waste, and supports supply chain optimization by reducing operating expense and resource inefficiency.

Raw Material and Component Consumption

Tracking raw material usage improves procurement process optimization and helps manage procurement costs. This ensures efficient sourcing and reduces overhead cost throughout the end-to-end supply chain.

Machine Fuel and Energy

One of the important supply chain cost drivers is energy consumption. Managing fuel and energy costs through green initiatives helps minimise operating expense and supports sustainable cost reduction strategies across production facilities.

Labour and Wages

Production cost and working capital management is directly influenced by labour and wage costs. The efficiency of the workforce will guarantee the reduction of operating costs, which is helpful in ensuring slender manufacturing and improved cost analysis of the supply chain.

Waste and Scrap Management

Effective waste and scrap management reduces operating expense and enhances supply chain efficiency. Recycling initiatives and smart process design contribute to long-term cost reduction strategies and sustainable value chain analysis.

Operation Cost

Operation cost includes all daily expenses essential for smooth supply chain efficiency. It encompasses procurement cost, logistics cost, salaries, IT systems, and facilities. Effective control of these through strategic cost management improves productivity, supports supply chain optimization, and reduces waste in the end-to-end supply chain.

Resource Allocation

The allocation of resources will be done properly to balance the workload and keep the operating expense as low as possible. Optimised staffing, equipment use, and capacity planning enhance working capital management, aligning labour and material usage with demand, thus improving supply chain efficiency and supporting long-term cost reduction strategies.

IT System Maintenance

The costs of IT system maintenance gives way to the overall operation cost and overhead cost. Constant system upgrades enable proper data tracking and cost analysis that are related to supply chains and provide smooth integration of supply chains that will be used to optimise and provide visibility in the costs of procurement, inventory and distribution cost factors.

Administrative Overheads

The HR management, record-keeping, and compliance costs are administrative overheads. Controlling these helps reduce operating expense and improve cost structures, enhancing strategic cost management and efficiency across the end-to-end supply chain by streamlining non-core operations.

Utilities and Facility Management

Facilities management and utilities add to recurrent operation costs such as the energy, water and maintenance costs. Optimising these reduces warehousing expense, supports cost reduction strategies, and sustains supply chain efficiency by improving resource use and operational performance.

Warehousing Costs

Warehousing costs form a major part of the total inventory cost. They are rent, automation systems, security and utilities. Monitoring these through supply chain cost analysis ensures lower warehousing expense, improved cost structures, and enhanced supply chain optimization.

Warehouse Construction/Rent

Operating expense and overhead cost is influenced by warehouse rent or building construction. Strategic location planning and lease management improve distribution cost control, boost working capital management, and enhance supply chain efficiency through optimal storage capacity utilisation.

Equipment and Automation

The optimization of the supply chain can be facilitated through the investment in the equipment and automation to minimise the number of manual mistakes and labour expenses. Smart tools lower inventory cost and warehousing expense, aligning with cost reduction strategies and long-term strategic cost management.

Utilities

Electricity, cooling, and water used in warehouses are some of the utilities that accumulate logistics costs and operating expenses. Efficient usage improves supply chain efficiency, supports collaborative cost reduction, and reduces environmental impact while enhancing facility performance.

Security, Insurance, and Safety Compliance

Warehousing cost is added by security systems, insurance coverage and safety compliance. Proper implementation minimises risk, maintains compliance, and reduces potential inventory holding cost, strengthening overall value chain analysis and long-term operational sustainability.

Distribution Cost

Distribution cost includes expenses associated with product movement through the end-to-end supply chain. It comprises the cost of transportation, freight expenses, packing and delivery expenses. Optimising these reduces logistics cost, enhances supply chain efficiency, and supports effective cost reduction strategies.

Packaging and Labelling

Distribution cost and operating expense are directly affected by packaging and labelling. Efficient design reduces material waste and handling time, supporting strategic cost management and enhancing overall supply chain efficiency.

Last-Mile Delivery Expenses

Logistics cost is increased by the last-mile delivery. Efficiency in routes and delivery time can enhance the optimization of supply chain, minimization of transportation expenses, and management of working capital.

Freight Charges

Freight cost affects overall distribution cost and operating cost. The rates negotiation and using an efficient carrier would minimise logistics cost that facilitates joint cost reduction and more precise supply chain cost analysis.

Reverse Logistics for Returns

Reverse logistics is a huge contributor to the distribution cost, handling fees, and overhead cost. Streamlining product returns through technology integration minimises waste, improves value chain analysis, and supports cost reduction strategies. Efficient return management recovers value from returned goods, reduces operational inefficiencies, and enhances overall supply chain efficiency across the end-to-end supply chain.

Quality Costs

The cost of quality incorporates inspection, prevention of defects, and costs of failures required in order to be at the standard. Effective management reduces production costs, prevents rework, and boosts supply chain efficiency. Integrating quality monitoring into strategic cost management ensures continuous improvement, minimises waste, and strengthens cost structures across the end-to-end supply chain through optimised resource allocation.

Inspection and Testing Expenses

Testing and inspection ensure product reliability while controlling production cost and inventory cost. Regular audits find fault in the initial stage, which minimises waste and enhances optimization of supply chains. Using automated quality tools improves accuracy, minimises operating expense, and supports strategic cost management through better compliance, consistency, and value chain analysis across production lines.

Customer Dissatisfaction and Lost Sales

The result of bad quality is lost sales, returns and high operating costs. Addressing issues proactively through value chain analysis enhances reputation and customer retention. Continuous improvement and collaborative cost reduction minimise supply chain cost drivers, improve profitability, and maintain consistent supply chain efficiency across all operational functions and distribution networks.

Rework and Scrap Due to Defects

Scrap and rework due to defect products increases the cost of production and overhead cost. Applying preventive quality control and cost reduction strategies lowers waste and boosts efficiency. Monitoring processes through supply chain cost analysis ensures consistent supply chain efficiency and strengthens sustainability across the end-to-end supply chain operations effectively.

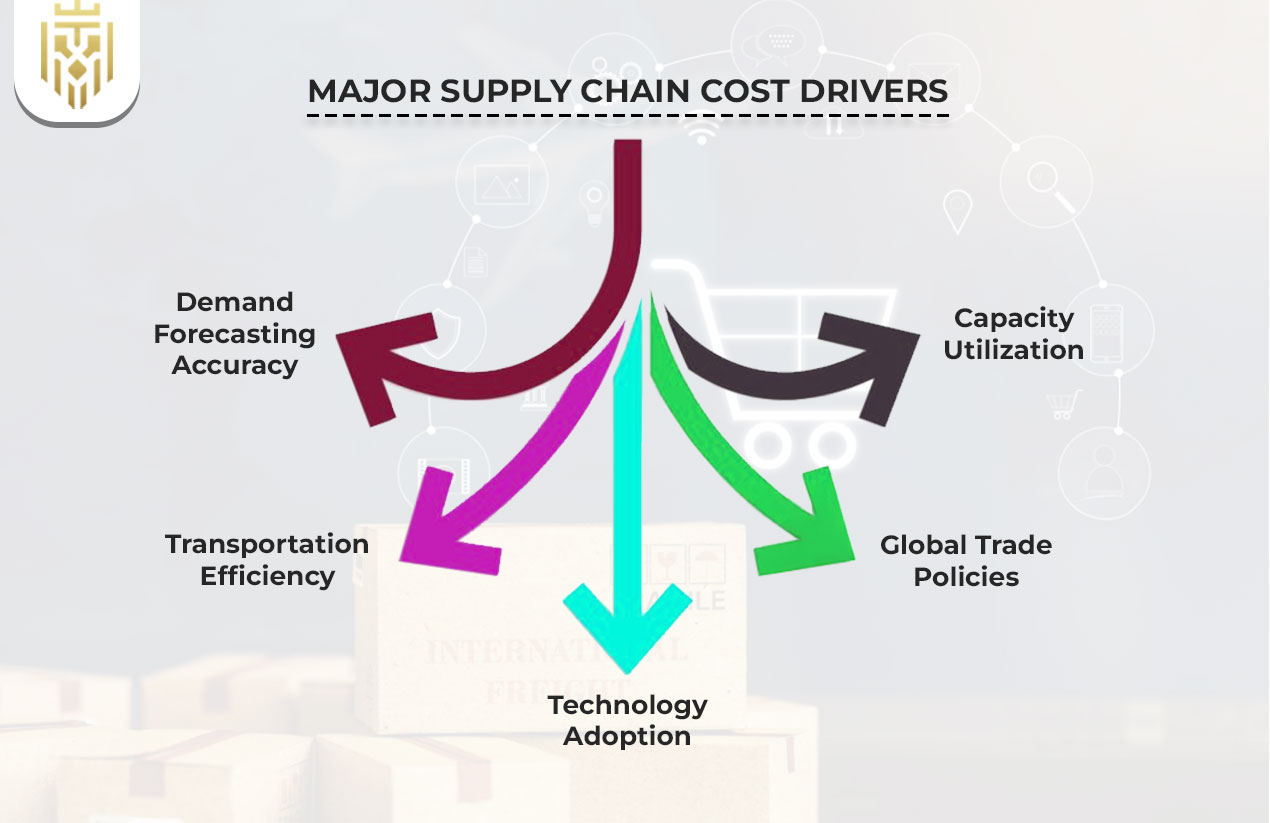

Major Supply Chain Cost Drivers

The major supply chain cost drivers define how expenses evolve throughout the end-to-end supply chain. These include procurement, logistics, production, and inventory cost components. Effective management of these areas enhances supply chain efficiency, supports strategic cost management, and ensures long-term competitiveness through targeted cost reduction strategies and improved operational visibility.

Demand Forecasting Accuracy

Accurate demand forecasting reduces inventory cost, prevents stockouts, and minimises excess warehousing expense. It improves supply chain efficiency and enhances planning accuracy. Incorporating predictive analytics enables better decision-making, optimised procurement cost, and stronger working capital management, ensuring smoother supply chain optimization and efficient alignment between market demand and production capabilities.

Transportation Efficiency

The efficiency of transportation has a direct impact on the cost of logistics, costs of distribution and freight charges. Routine optimization tools, real time tracking and consolidation of shipments reduce operating cost. Enhancing transport coordination supports cost reduction strategies, improves supply chain optimization, and strengthens strategic cost management across the end-to-end supply chain for timely product delivery.

Technology Adoption

Adopting advanced technology improves supply chain efficiency, transparency, and cost visibility. Automation tools minimise cost of operation, reduce overheads cost, and optimise procurement processes. Integrating data systems enhances value chain analysis and fosters supply chain optimization through predictive analytics, ensuring consistent performance and adaptability across evolving market environments.

Global Trade Policies

Global trade policies influence import duties, procurement costs, and transportation costs within the end-to-end supply chain. Compliance, reducing delays and aiding cost analysis of the supply chain are all aspects that are achieved through monitoring regulations. Strategic sourcing decisions and cost reduction strategies align business operations with policy changes to maintain supply chain efficiency and financial stability.

Capacity Utilization

Maximised capacity utilisation increases productivity, and decreases production cost. Scheduling supply and demand avoids wastage of resources and restricts the cost of operation. Through strategic cost management and value chain analysis, businesses achieve maximum efficiency, strengthen cost structures, and improve responsiveness across the end-to-end supply chain network.

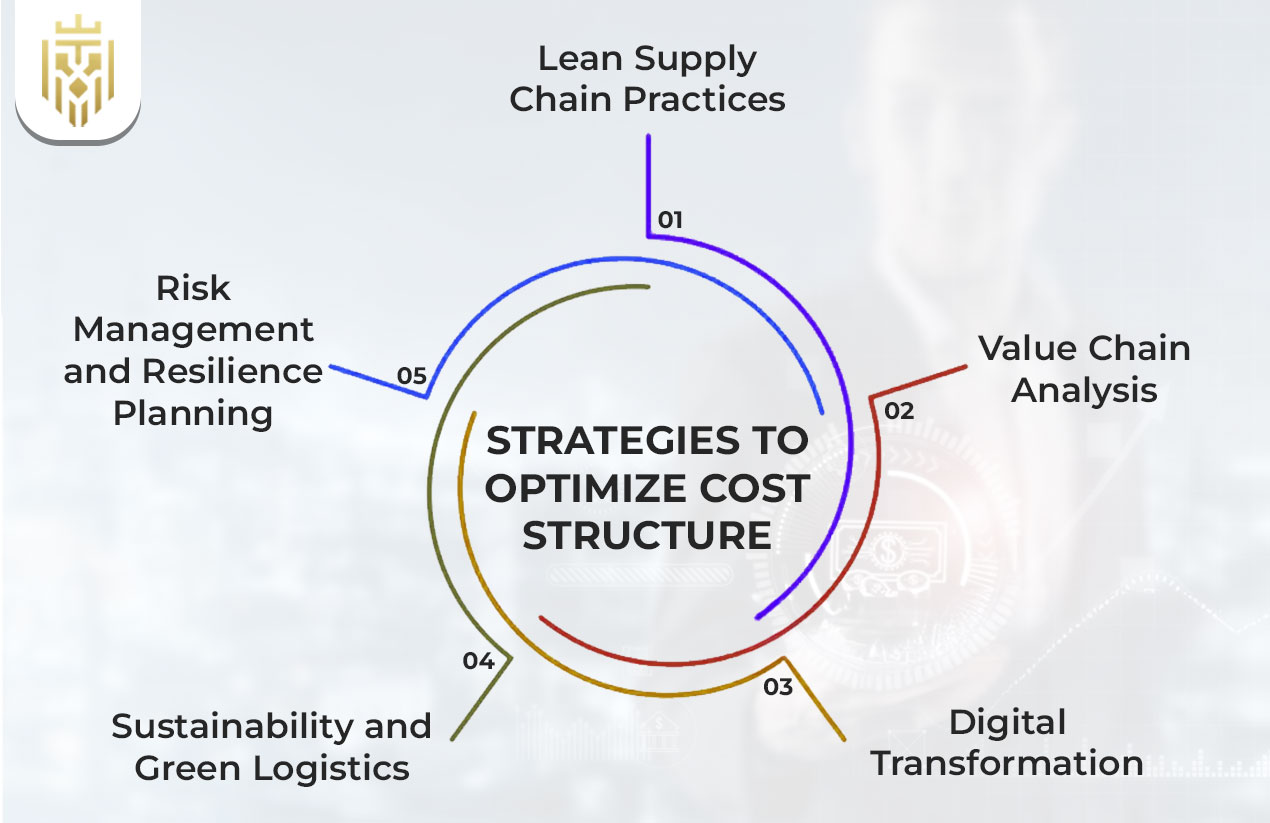

Strategies to Optimize Cost Structure

Developing effective cost reduction strategies ensures profitability and resilience across the end-to-end supply chain. Implementing strategic cost management, technology-driven supply chain optimization, and value chain analysis enhances performance, reduces inefficiencies, and maintains supply chain efficiency while controlling procurement cost, logistics cost, and overall operational expenditure sustainably.

Lean Supply Chain Practices

Lean supply chain practises eliminate waste, reduce inventory costs, and optimise production costs. Streamlined workflows improve supply chain efficiency and responsiveness. Implementing these practises supports strategic cost management, improves cost structures, and enhances overall performance by minimising unnecessary resource consumption within the end-to-end supply chain.

Value Chain Analysis

Value chain analysis identifies high-cost areas and enhances supply chain optimization. It ensures effective cost reduction strategies, improves procurement process optimization, and supports working capital management. By examining each operational stage, businesses enhance supply chain efficiency, achieving stronger strategic cost management across production, logistics, and procurement activities.

Digital Transformation

Digital transformation enhances the efficiency of the supply chain by automating, analysing data, and predicting. It saves cost of operation, improves visibility and promotes collective cost-cutting. The use of smart systems enhances supply chain cost analysis and allows to undertake strategic cost management proactively to provide constant supply chain optimization and improved financial control.

Sustainability and Green Logistics

Green logistics and sustainable practises reduce the cost of transportation, waste, and efficiency of the supply chain. The integration of green efforts fits the cost management strategy and value chain review and can increase long-term competitiveness and supply chain cost drivers, by reducing environmental costs considerations and cost focus on innovation in the supply chain.

Risk Management and Resilience Planning

Proper management of risks enhances business continuity and minimises operating costs due to the disruptions. It assists in strategic cost management, suppressed supply chain cost drivers, and responsiveness. Combining contingency plans, supplier diversity, and predictive analytics make supply chain more efficient and guarantee the optimization of supply chain in the long term across the end-to-end supply chain.

FAQs

1. How do investment costs affect long-term supply chain performance?

The cost of investment has impacts on optimization of supply chain by ensuring enhanced infrastructure, lowering cost of holding inventory and efficiency. Strategic investments help in cost cutting measures and improved efficiency of the supply chain in the long run.

2. What role do quality costs play in overall supply chain expenses?

Costs of quality affect the cost of production and cost of inventory and cost of operation. Quality management minimises waste, increases value and aids in strategic cost management and this improves the overall end-to-end supply chain performance.

3. What is the impact of outsourcing distribution on cost structures?

Outsourcing distribution transforms cost structure, transportation cost is optimised, warehousing costs decreased and flexibility is increased. It assists with the procurement and sourcing strategy and allows cost-cutting and quick-reaction in the market.

4. How does logistics network design reduce warehousing and distribution costs?

The design of a good logistics network lowers warehousing costs, distribution costs and handling costs. It improves supply chain efficiency, aids cost reduction strategy, and reduces overhead cost by optimal choice of facility location as well as route.

5. How does sustainability reshape supply chain costs?

Sustainability transforms the costs through reduction of logistics cost, transportation cost and operating expense. Green initiatives increase cost analysis in supply chain, increases efficiency and contributes to strategic cost control by minimising environmental impact.