What is Transloading?

Transloading refers to the movement of goods through various modes of transport, e.g., rail, truck, or shipping, and then delivering them to the place of destination. This transloading logistics model increases flexibility in the complex supply chain.

Transloading vs. Intermodal Transport vs. Cross-Docking:

Unlike transloading, intermodal does not remove the goods from the same container and has very minimal handling. Cross-docking conveys products across trucks without a warehouse. It is usually more manual and flexible in different modes of transportation. The transloading facilities have been created specifically to make such intermodal transfers with efficiency.

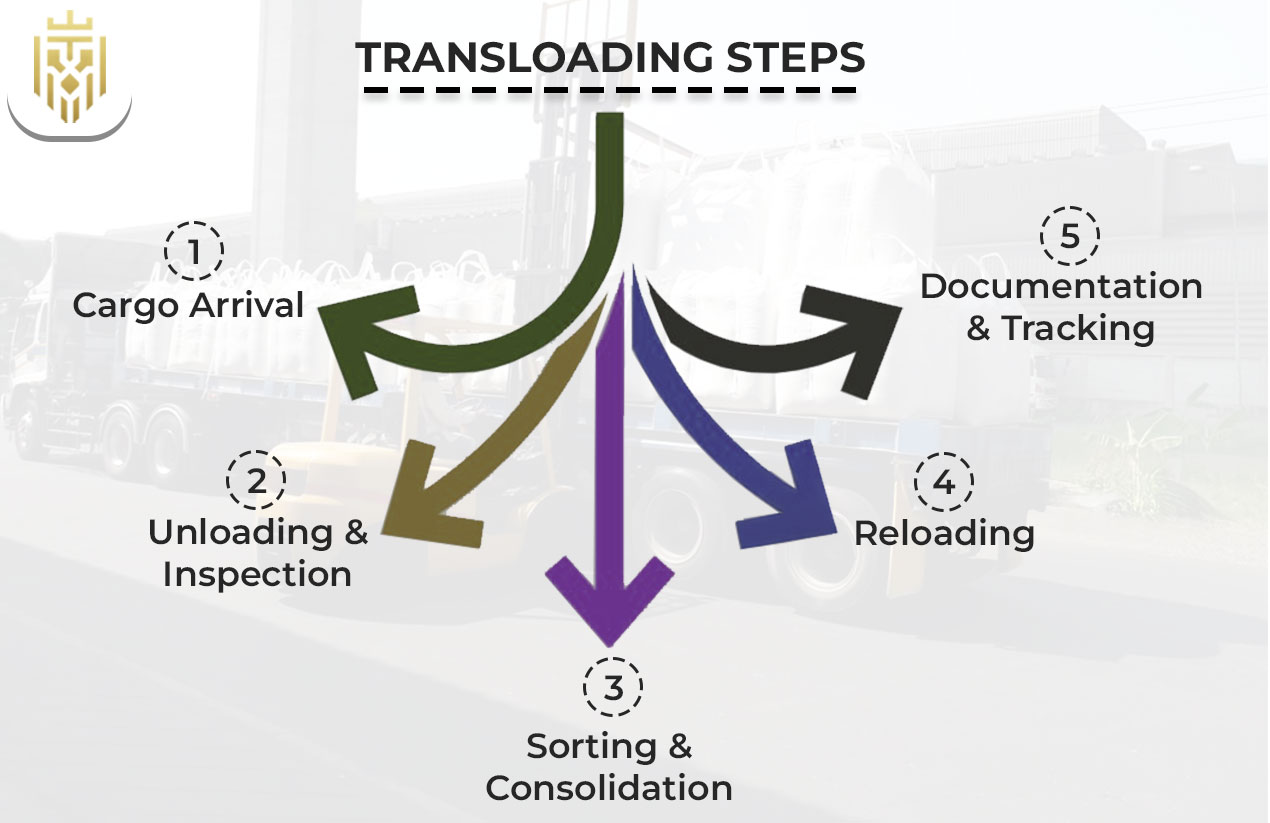

What are the steps involved in transloading?

The processes of a transloading facility include a number of various stages with the view of making the goods efficiently change modes of transportation. Every single step must be coordinated to ensure the integrity of the cargo, along with the correct records relative to the chain of supply.

Cargo Arrival

Goods enter a transloading facility by a single mode of transport: either a truck, rail, or sea. This entrance point is the first step of the process of transloading logistics, where they prepare shipments and prepare to hand them over to the next mode of transportation.

Unloading & Inspection

In this phase, transloading of goods is done in a way that they may not be damaged. Inspections check the trucks to see whether the cargo is fine and whether everything is counted correctly, and this is vital to ensuring an easy transition in the downstream mode of transportation and customer satisfaction.

Sorting & Consolidation

Consolidation of travelling cargo can be done according to destination or type of transportation mode to be used. The action in the transloading logistical chain ensures that the shipment is made according to the most effective and economical path of transport.

Reloading

The process of sorting is followed by the transfer of goods to their next mode of transport. This is the realm of practicality of transloading, meaning transporting the product between different carriers in order to maximise those routes taken and to reduce the total transportation time.

Documentation & Tracking

The documentation used in shipping is revised after transloading and includes up-to-date carrier information. Real-time tracking software is useful in ensuring transparency in the transportation process, which makes it accountable and timely.

Key Benefits of Transloading

The advantages of transloading logistics are quite numerous, as they are associated with such results as decreased costs, flexibility, and improved inventory control. The option of multiple modes of transportation enables companies to streamline the performance of their supply chain and improve service reliability.

Cost Efficiency

Cost is saved because the most cost-efficient mode of transportation is used at any step. Transloading logistics can be used to even out operational costs by using the less expensive long-lateral options, such as rail, and shorter final-mile delivery via truck.

Flexibility & Agility

Transloading has flexibility in case of the delay of one mode. Switching mode of transport to alternate modes is a guarantee of recovery, less idle time, and quicker response to altering demand or emergent interruptions in the supply chains.

Speed & Reliability

Speed is maintained by optimisation of the mode of transportation by transloading the transport alternatives in the quickest routes available. This flexibility allows sustaining the supply chain schedules and makes steady service commitments.

Inventory Control

The transloading facilities can be used to consolidate inventory near end points. This makes judicious utilisation of modern transportation, lessens unnecessary storage time, and endorses lean supply chain schemes with lessened overhead expenses.

Environmental Impact

Businesses are able to switch their shipments to the mode of transportation that is environmentally friendly, such as rail, through transloading. This will curb the use of carbon travel without compromising delivery efficiency, supporting the logistics strategies with environmental sustainability ambitions.

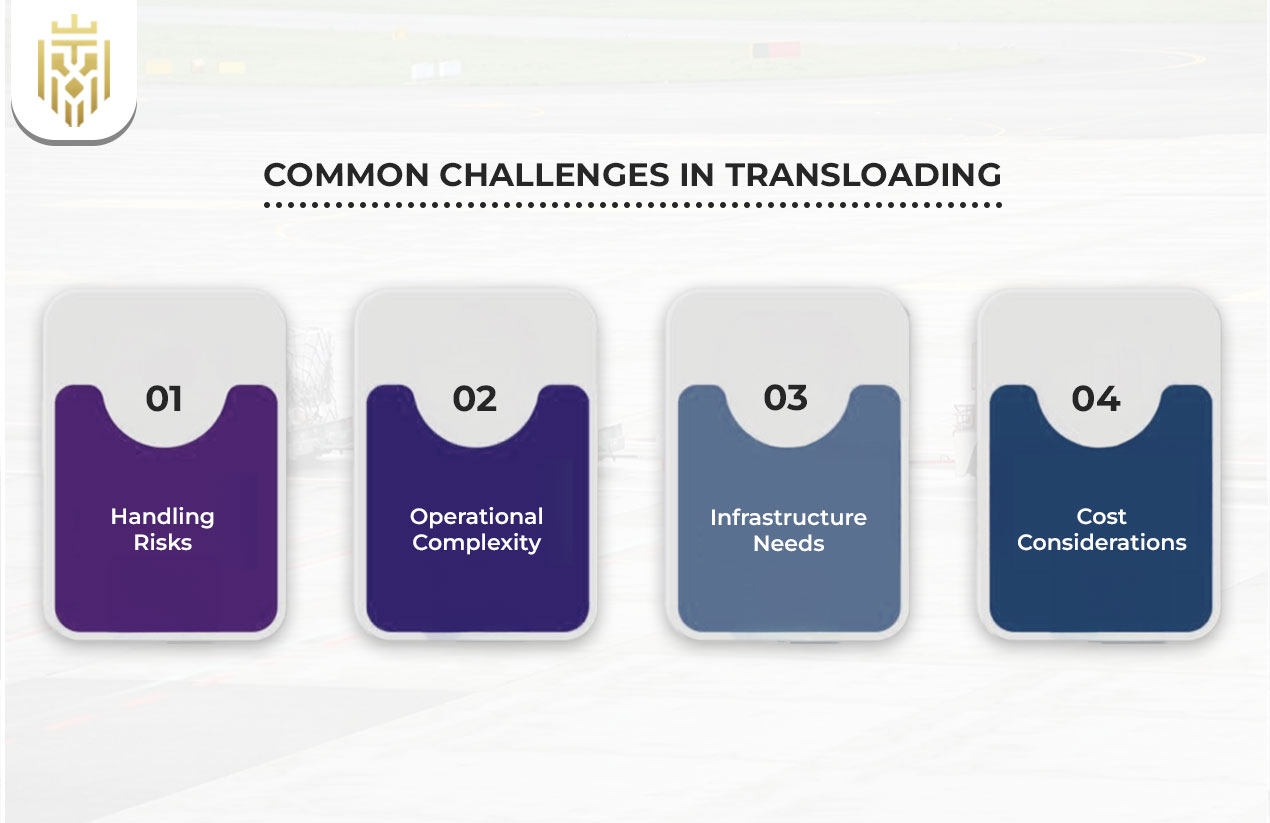

Common Challenges in Transloading

Transloading logistics does not come without its problems that involve risk management, infrastructure requirements, and complexity. This requires competent handling of such risks with an opportunity to leverage the advantages of the diversified modes of transport.

Handling Risks

During each transfer of goods, additional hazards to handling goods occur as they undergo transloading. The careful inspection and professional procedures address the risk of losses or destruction in the process of switching between different means of transport.

Operational Complexity

Switching between carriers and transloading locations is a process that has to be planned. This requires the skills of a proper plan to transport one mode to another without disrupting the process, causing loss of time and resources.

Infrastructure Needs

A transloading facility should possess machines that facilitate quick and safe transfers of cargo. These investments help to allow logistics support of transloading as it lowers risk, increases transfer speed, and improves efficiency of operations by handling them correctly.

Cost Considerations

Handling charges are reflected in the total costs, though these are mitigated by the savings accrued due to more prudent transport mode selection. Transloading usually diminishes long-distance trucking, which is costly, and diversifies it to cheaper and efficient alternatives.

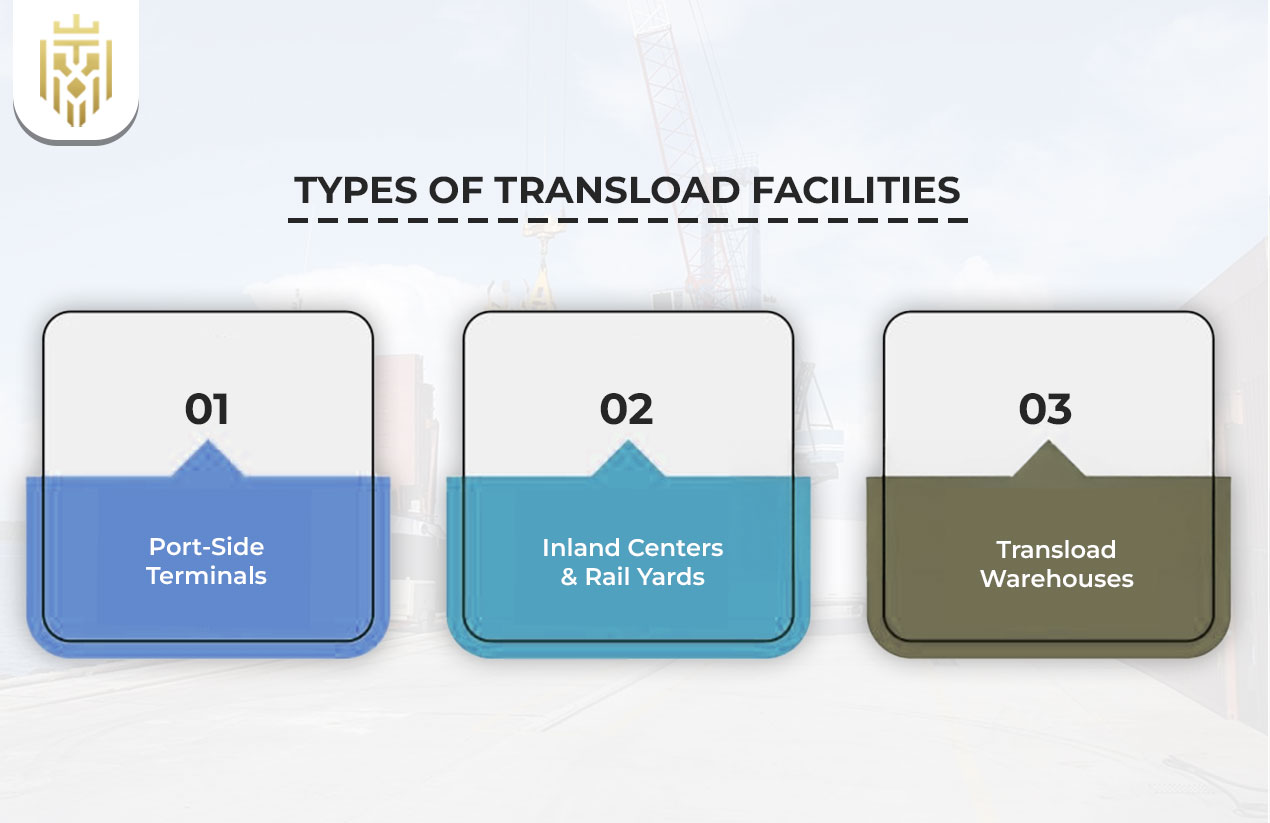

Types of Transload Facilities

There are numerous types of transloading facilities that are suitable for different needs, such as port-side terminals, inland centres & rail yards, and transload warehouses. These hubs connect several means of transportation and allow the companies to develop personalised and cost-effective approaches to the supply chain.

Port-Side Terminals

Port-side terminals deal with cargo that is being transferred out of ships to another form, such as rail transport or road transport. Transportation between sea freight and inland distribution networks is made smoother with the help of such transloading facilities.

Inland Centres & Rail Yards

Inland centres and rail yards facilitate truck-to-rail transloading. They decongest the ports and expand mode transportation outside regional routes deeper into the mode transportation network, and allow long-haul freight transportation to be executed efficiently.

Transload Warehouses

A transloading site can consist of a warehousing facility to facilitate sorting, storage of goods on a short-term basis, and consolidation. This eases operation and allows for a more manageable transition among different means of transportation in different modes.

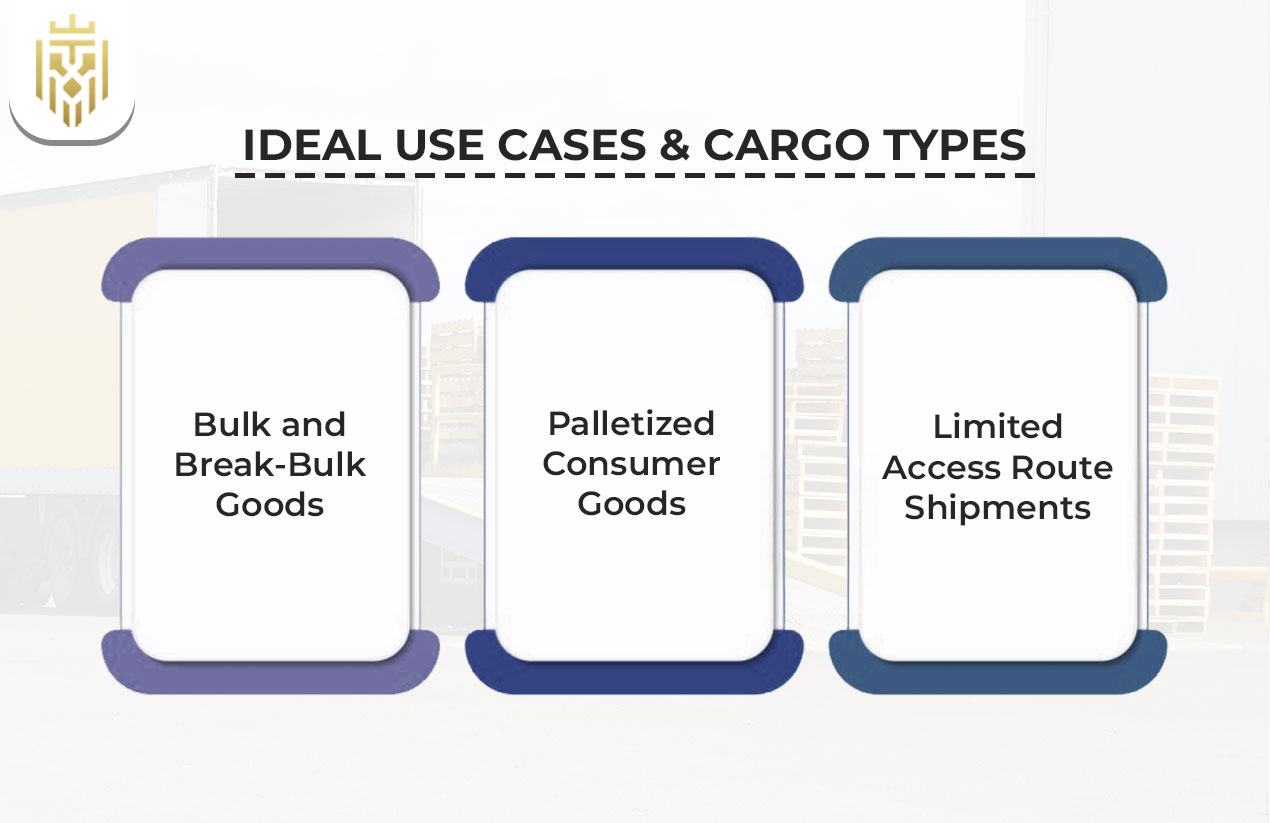

Ideal Use Cases & Cargo Types

Transload logistics are beneficial to any industry that requires flexibility, whether for bulk materials or consumers. It is useful in the management of complex delivery routes and the promotion of efficiency in the different segments of the mode of transportation.

Bulk and Break-Bulk Goods

Transloading facilities are common in industries that ship goods made of heavy materials because this type of facility is used to move goods between different modes of transportation. This makes it cost-effective and accessible in transporting bulky, cumbersome freight to the inland or across the regions.

Palletized Consumer Goods:H3 – Bulk and Break-Bulk Goods

Transloading facilities are common in industries that ship goods made of heavy materials because this type of facility is used to move goods between different modes of transportation.This makes it cost-effective and accessible for transporting bulky, cumbersome freight to the inland or across the regions.

Palletised Consumer Goods

Transloading logistics are advantageous to consumer products because they will be changed in mode of transportation close to regional hubs. This reduces logistic times, keeps up with supply chain demands, and uses modes of transportation in a better way.

Limited-Access Route Shipments

The best potential application of transloading is when shipments are received in limited access ports/routes that may necessitate the breaking of shipped containers. This allows making adjustments in terms of mode of transportation in order to make the last leg of delivery.

Transloading Compared to Other Models

Unlike intermodal or cross-docking logistics, transloading logistics does imply physical relocation of the goods between the modes of transportation. This aspect of practical activity makes the supply chain more flexible when a single mode is not effective in serving the complete route.

Intermodal

Intermodal makes containers enclosed; handling is minimal. By contrast, transloading can disaggregate bulk shipments to redistribute along different means of transportation routes, providing greater routing control.

Cross-Docking

In cross-docking, there are rapid exchanges between trucks and no storage. Transloading locations, though, tend to move products across different types of modes of transportation and assist with longer supply chains that have more hand-offs necessary.

Transhipment

Although transhipment is generally used to describe the pirating of cargoes, transloading logistics is dedicated to transportation switches in the strategic mode. The aim is to optimise routes, but not just transportation of cargo in the same shipping ecosystem.

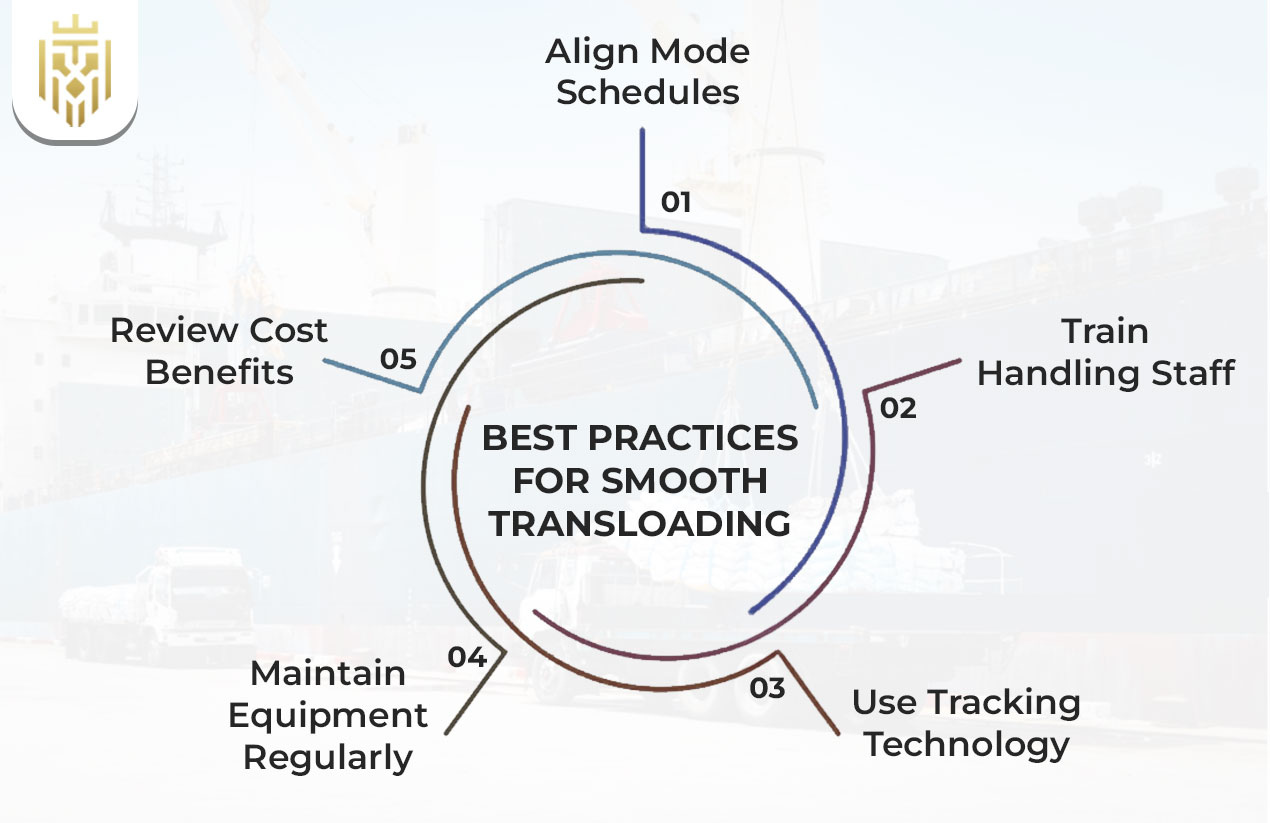

Best Practices for Smooth Transloading

Although transhipment is generally used to describe the pirating of cargoes, transloading logistics is dedicated to transportation switches in the strategic mode. The aim is to optimise routes, but not just transportation of cargo in the same shipping ecosystem.

Align Mode Schedules

The synchronisation of transport modes provides the reduction of transfers and the shortest wait time in the transportation mode. Such alignment facilitates less disorderly transloading, low storage demands, and an efficient flow of supply chains without congestion.

Train Handling Staff

Training guarantees safe transloading and no damage to goods. The effective mode-changing methodology decreases the risk during the change of transportation modes, making transloading logistics more reliable and ensuring cargo integrity throughout the journeys.

Use Tracking Technology

Such technology as RFID promotes improved visibility in transloading facilities. These are devices that follow the movements of cargoes, monitor timelines, and aid in an efficient shift across mode networks of transportation franchises across the different aspects of the supply chain.

Maintain Equipment Regularly

Transloading facilities that are well-maintained enhance reliability in operations. Downtime is minimised by using functional equipment that provides a smooth transfer between one mode and another and boosts the overall effectiveness of the logistics performance.

Review Cost Benefits

Companies have to compare the cost against the benefits in the process of choosing the mode of transportation strategies. Frequent reviews will also help to keep the transloading logistics relevant to the cost efficacy and adapt to the changing supply chain objectives.

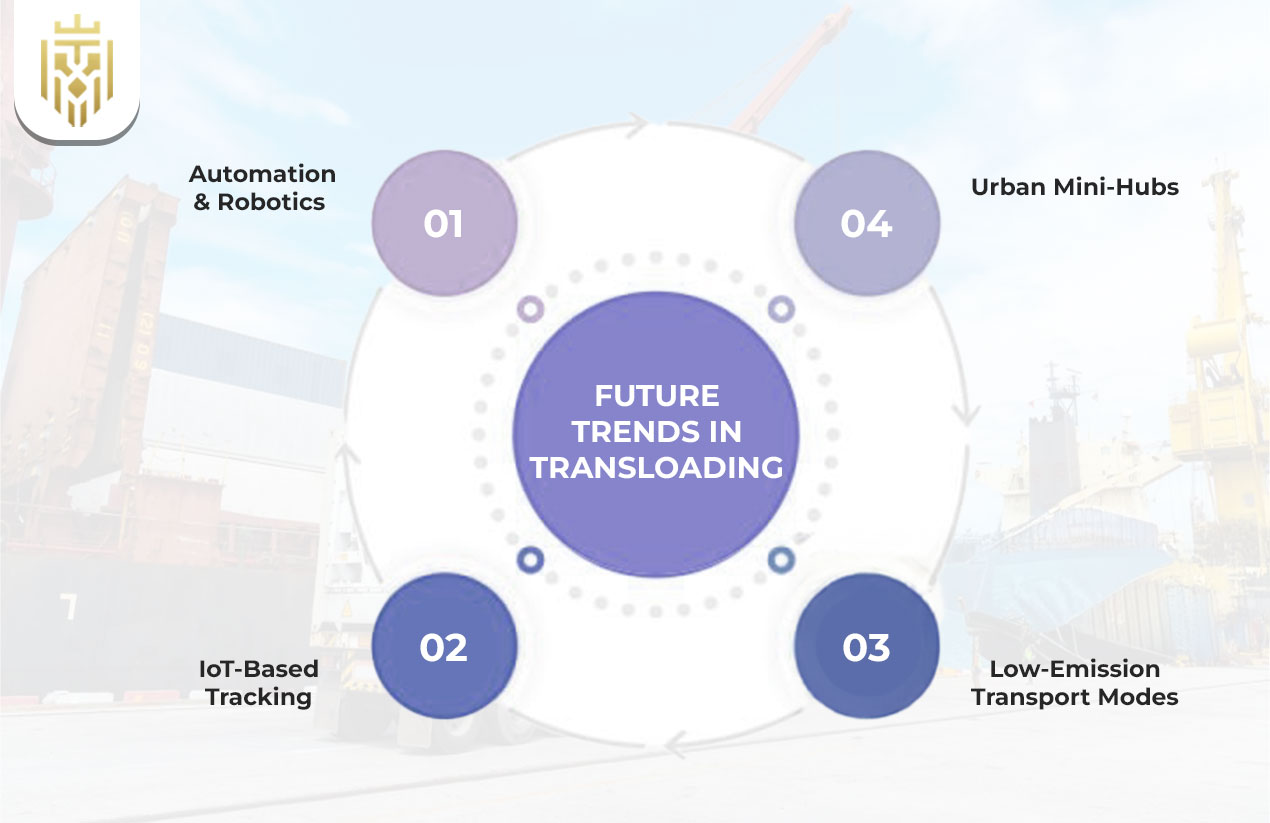

Future Trends in Transloading

Logistics of transloading develops further in accordance with advances in technologies and sustainability objectives. The vision of the future is to increase the effectiveness of mode transportation networks that are based on automation and green technologies.

Automation & Robotics

Transloading involves automation, which minimises manual work and enhances efficiency. The use of robotics also facilitates the transfer between different modes, and the turnaround time is made quicker, and the operational cost is reduced.

IoT-Based Tracking

The IoT sensors will provide a real-time inspection of transloading logistics operations. Such tools help monitor mode transportation, where the cargo can be traced through its transformation, and the quality control requirements are met.

Low-Emission Transport Modes

Transportation by low-emission mode is becoming popular in transloading logistics. Companies can change freight to less environmentally harmful forms, such as rail, and divert part of the freight to rail.This will decrease environmental effects, and it will not jeopardise the efficiency of the supply chain operations.

Urban Mini-Hubs

There is also the rise of mini transloading factories that are used to cater to urban logistics. These terminals reduce modal switching efforts between modes of transport and increase the agility of last-mile distribution in high-density or inaccessible areas.

FAQs

1) How is transloading different from intermodal shipping?

Transloading is the transfer of goods between modes, whereas in intermodal, the cargo is kept in the same container as it traverses modes. Knowing what transloading is leads to the understanding that it is flexible, whereas intermodal has container integrity and reduced handling as its priorities.

2) Does it increase damage risk?

Yes, transloading may create an increased risk of damage because of handling during mode transfer. Good transloading logistics, facilities, and well-trained employees assist in reducing the possible damage or loss.

3) What types of goods are best for transloading?

Bulk materials, heavy equipment, palletised consumer goods, and shipments requiring a multi-modal or consolidation opportunity are perfect candidates for transloading, given the flexibility of handling and routing.

4) Can it reduce shipping costs?

Indeed, transloading minimises shipping expenses because it enables businesses to utilise the low-cost method of transport as well as optimise the trip, particularly when shipping by rail, ocean, and road carriers in concert.

5) What tech helps improve transloading?

RFID, IoT sensors, automated equipment, and superior tracking systems can optimise the transloading logistics process and make it much more visible, accurate, and efficient because they provide insight into the transfer and transportation process.