Understanding the Role of ERP in Supply Chain Management?

ERP systems are designed to bring together various business operations under a single platform, and supply chain management is one of the most important areas where this integration proves valuable. Such management in ERP involved the comprehensive governance over all the flows, goods, data, and money specifically involved by a particular product or service from the start to the finish within the supply chain, all in one accord. With this, visibility is increased, communication is quicker, and efficiency is improved.

Integrating Supply Chain Management and ERP

Integration of supply chain management activities with ERP software creates a fast, streamlined process in which duplicated processes are eliminated and work productivity is maximised. All activities related to the supply chain are linked through ERP and help any company manage suppliers, inventories, orders, and delivery schedules more efficiently. In such combinations, all departments use current information and as such, minimise timings of delay or miscommunication.

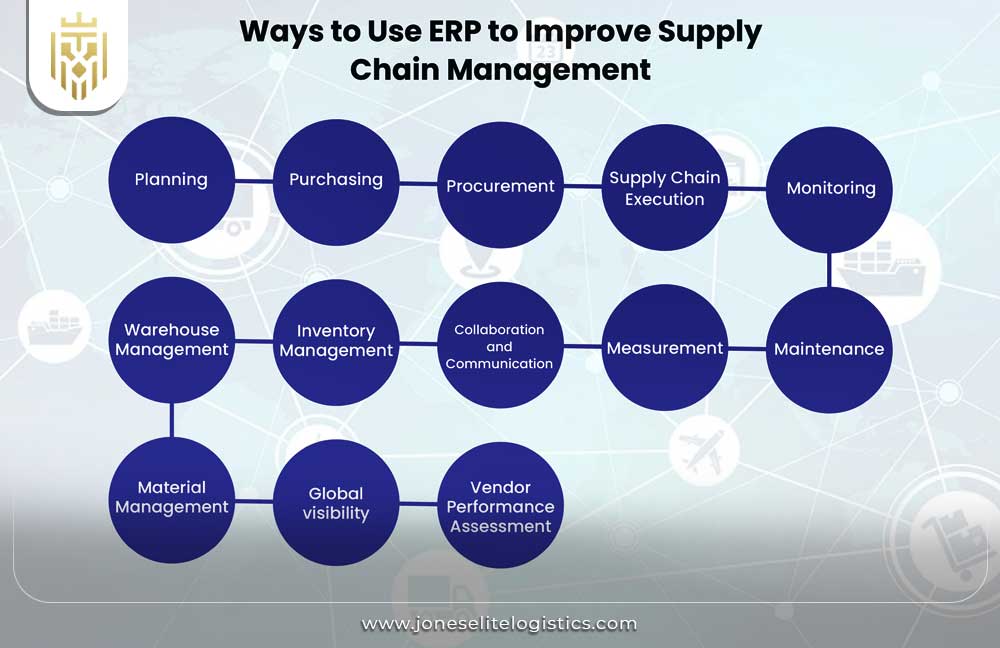

What are the Ways to Use ERP to Improve Supply Chain Management?

ERP systems offer specific tools and modules that support various functions within the supply chain, allowing businesses to make data-driven decisions and ensure smooth operations.

-

Planning

Effectively plan. ERP tools are the tools that forecast the demand and coordinate the supply; they reduce inventory mismatches.

-

Purchasing

Automated purchasing services such as order creation and approval and supplier communications.

-

Procurement

Centralised procurement system managed by the ERP that makes supplier management and cost control efficient.

-

Supply Chain Execution

Moreover, real-time information improves execution of orders, transport, and delivery timelines to meet customer expectations.

-

Monitoring

Tracking tools have been prepared to keep records of all activities in the supply chain, making it possible to act fast when resolving issues.

-

Maintenance

This involves regular schedules for maintenance within the ERP systems so that machines and systems that support logistics can be continuously functional.

-

Measurement

The performance indicators and analytics measure the effectiveness of supply chain activities and show improvement zones.

-

Collaboration and Communication

Internal team members and external partners keep in touch with shared data and workflows for a smooth handover.

-

Inventory Management

ERP tracks customer inventory levels and movement and leads stocks out again to avoid shortages and overstocking.

-

Warehouse Management

Warehouse operations, such as receiving, picking, packing, and dispatching, are managed efficiently within ERP.

-

Material Management

Material flow in the supply chain is traced in order to support accurate planning and waste reduction from it.

-

Global visibility

A single view of international operations will make great decisions in time for many areas and reduce the risks in international logistics work.

-

Vendor Performance Assessment

Make monitoring and evaluation of vendor performance in ERP systems to ensure better supplier relationships and accountability.

Benefits of using ERP in supply chain management

The integration of ERP with supply chain processes offers multiple benefits that improve daily operations and long-term strategy.

-

Reduced Overhead and Operational Costs

With streamlined processes and reduced manual effort, businesses see a decrease in administrative and operational expenses.

-

Flexible Supply Chain Solutions

Variations in order quantity, transportation routes and inventory available can be catered to because of this advantage.

-

Workflow Automation

Systematised handling of routine duties speeds operations and reduces possibilities of human error.

-

Fewer Bottlenecks

Such visibility and real-time data easily prevent slowdowns on most supply chain activities.

-

Increased Customer Retention

The precision in order fulfilment, coupled with speedier delivery, optimises customer satisfaction, which will result in repeated business.

How to Implement ERP Software?

Implementing ERP software requires a structured approach to ensure smooth integration with existing supply chain operations.

-

Select an ERP Software

Choose the right software, ERP solutions, and applications relevant to the size, type, and spend of your business.

-

Design and Configure the System

Adapt the ERP with your supply chain process so that it fits into your workflow.

-

Establish Integration Goals

Define what systems need to connect with the ERP and what outcomes you expect from the integration.

-

Data Preparation

Data must be cleansed and well organised for successful importation into a new system.

-

Integration of API

Use applications to connect ERP software solutions to other applications related to logistics, finances, and procurements through API connections.

-

Testing and Training

Thorough testing is required since it is basically necessary to find out if the system works well enough. Training staff will ensure that the application can be done easily every day.

-

Streamlining Your ERP System

Normalise processes further with data derived from the earliest use of the ERP.

-

Maintenance and support

This should include constant updates and constant support to ensure the operating efficiency of the system over a long time span.

FAQs

1) What is supply chain management in ERP?

It is a process that refers to the use of ERP software for supply chain-related activities such as procurement, inventory, warehousing, and delivery.

2) How do you implement an ERP system step by step?

The process entails selecting the appropriate one for the organisation – configuration to suit business operations. API integration – data preparation – testing – the training of personnel – support.

3) What are the ways to use ERP to improve supply chain management?

By facilitating planning, purchasing, inventory control, warehouse operations, supplier management, and real-time monitoring, ERP systems increase supply chain performance.

4) What is the role of ERP in supply chain management?

By facilitating planning, purchasing, inventory control, warehouse operations, supplier management, and real-time monitoring, ERP systems increase supply chain performance.