What is Stock Management?

Stock management means monitoring and overseeing how an organisation orders, stores, and uses its inventories. In a nutshell, stock management involves having the right amount of stock at the right time to meet customer needs without overstocking or understocking. Efficient stock management also proves favourable for logistics providers, giving better planning and timely deliveries which ultimately improve customer satisfaction.

-

Role of Technology in Stock Management

Digital tools and technology constitute the backbone of modern logistics. The Stock Management System provides the capability for an enterprise to have a direct view of its stock levels, up to the real-time tracking of goods and even then working through easy flows of materials to customers in the supply chain. The Retail Stock Management System provides companies with technological support in analysing information that will avoid delays, reduce wastage, and increase optimal decision-making.

-

Why is Stock Management Important?

Stock management ensures carrying the right amount of inventory always, reduces the cost of carrying an inventory, and prevents being short of products. It also improves the efficiency of the operation in terms of reduced disruptions and a specific flow of goods. It is also used to report financial statements accurately and forecasts.

What are the Differences between Stock Control and Stock Management?

Stock control tends to be resistant to change. It ensures that stocks are set and kept at the desired levels and also maintains stock movements at the correct time and place. Stock management is a wider term and goes beyond stock control into planning, forecasting, storage, and movement of stock across different supply chain stages. Essentially, stock control is only one part of stock management; stock management looks at all aspects.

Different Types of Stock Management

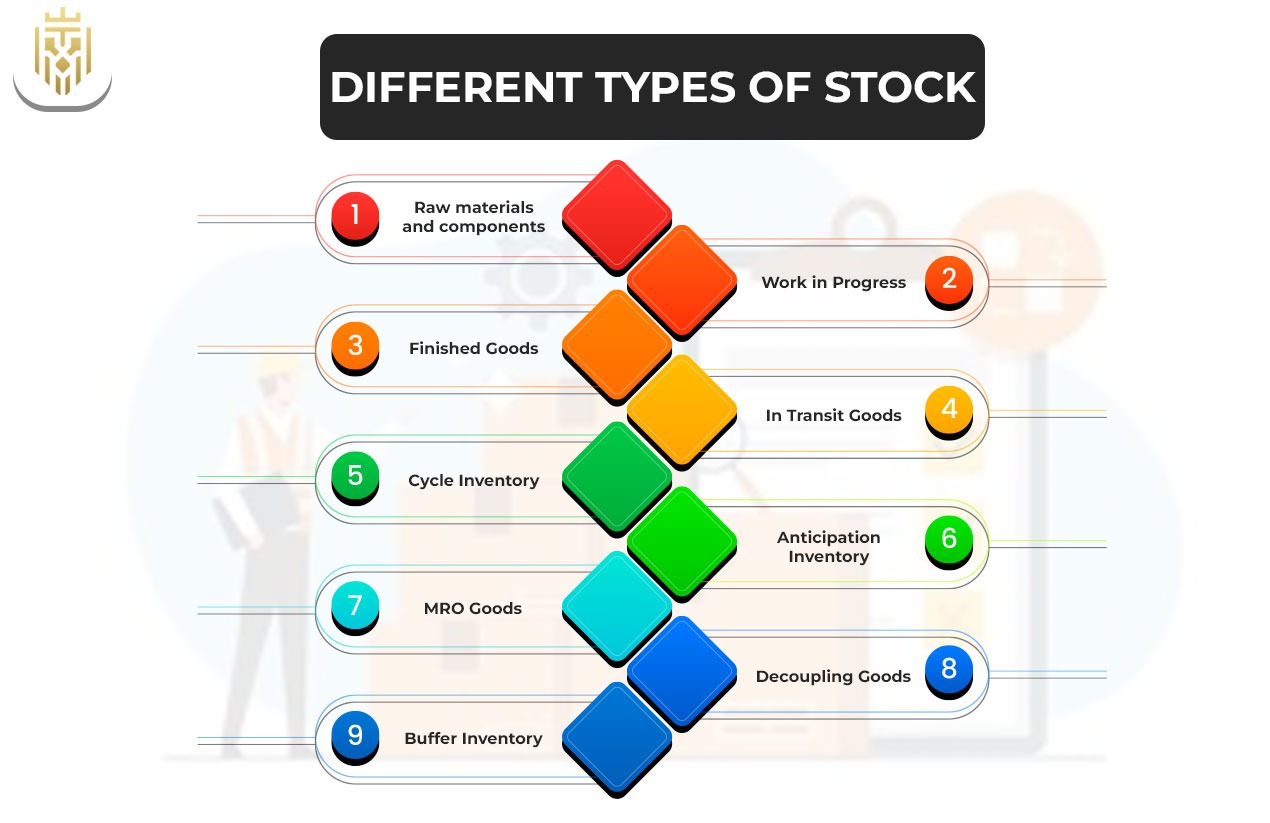

There are several categories of stock that logistics companies manage throughout the supply chain.

-

Raw materials and components

These are raw inputs for production. Logistics ensure that these are delivered on time, not interrupting manufacturing at any stage.

-

Work in Progress

Stock that refers to items still under manufacture. Efficient management of this particular stock will lower the production downtime.

-

Finished Goods

Commercial products are ready for sale. The storage and movement of finished products impact directly on the delivery time as well as the customer satisfaction.

-

In Transit Goods

These are goods that are on the way from one point to another location. Real-time tracking is required in this context to mitigate delay and misplacement.

-

Cycle Inventory

This is about periodic stock needed to satisfy normal sales demand. Accurate forecast stands out prominently in this case.

-

Anticipation Inventory

This is a commodity kept by businesses expecting programmed demand. Logistics will be consistent with market trends.

-

MRO Goods

These are the supplies needed for maintenance, repair, or operation, and they will not form part of the product when finally delivered.

-

Decoupling Goods

These are stocks held in between production stages to maintain the workflow in case of delays. It gives us freedom to operate.

-

Buffer Inventory

This safety net is to absorb shocks caused by spiking demand or hiccups in the supply chain.

Key Activities In Stock Management

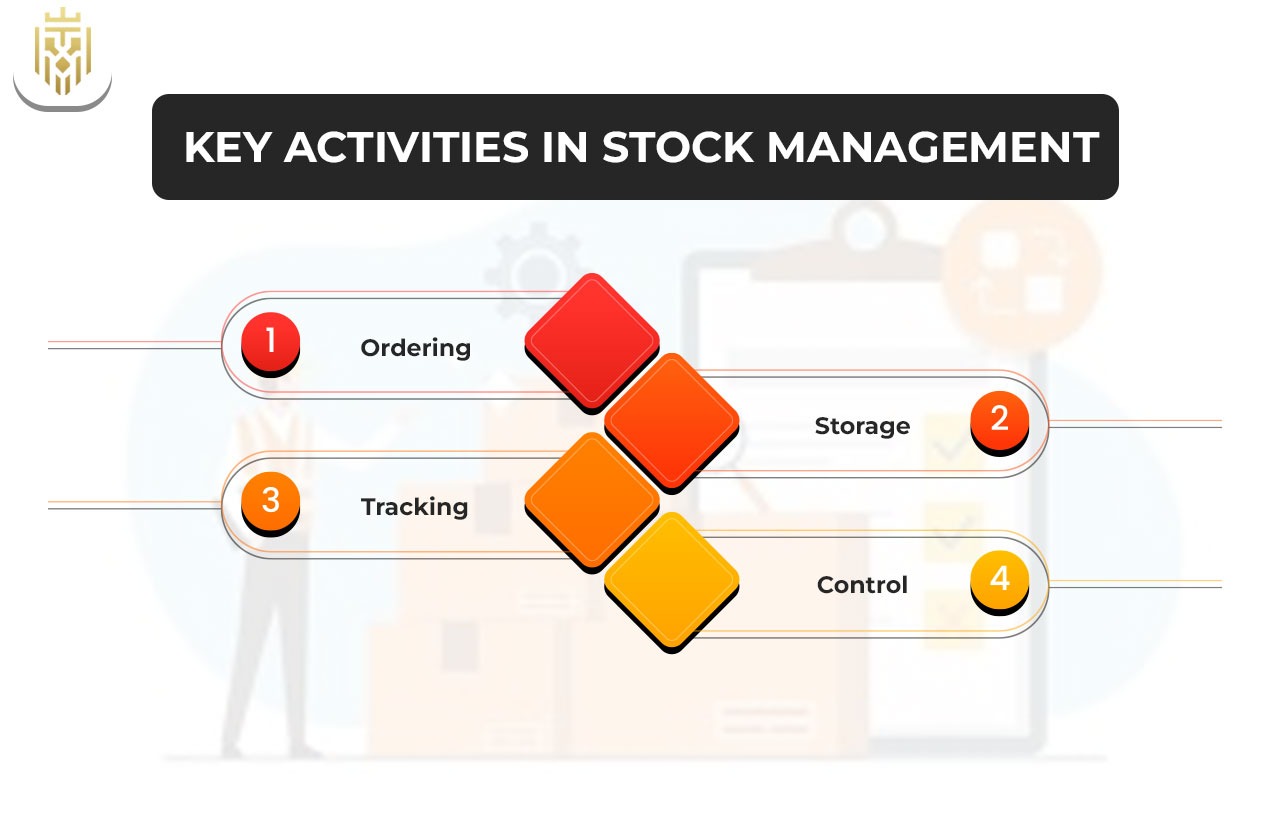

The core activities in stock management revolve around maintaining accuracy and flow within the inventory lifecycle.

-

Ordering

This activity includes when and how much stock to buy. It is through timely ordering that a continuous supply is maintained, thus keeping emergency buying at bay.

-

Storage

Proper storage makes sure that stock is kept under optimal conditions and also makes retrieval easy whenever needed.

-

Tracking

Tracking keeps a close eye on stock moving from supplier to warehouse to customer stage, ensuring transparency and accuracy.

-

Control

Control ensures that the inventory levels match what the business has really needed and also reduces ‘leakages’ that can occur due to theft, damage, or expiry.

How do we manage stock?

Successful stock management involves clear strategies and routine practices that support ongoing inventory optimisation.

-

Sort Your Inventory

Categorising inventories helps smoothen the process and create efficiency during order fulfilment.

-

Keep Track of All Product Details

Accurate stock data like product specifications, shelf life, and supplier details help to minimise errors and ensure better decisions.

-

Regularly Review and Adjust Inventory Levels

Frequent checking of stock allows alignment with current demand, thereby minimising excess or obsolete inventory.

-

Collaborate with your Team

Clear communication between departments will ensure that everyone understands the status and requirements of the stock.

-

Train your Team

A well-trained team ensures much of the work is carried out smoothly with better stock management upkeep.

FAQs

1. What is meant by stock management?

This is inventory management, where levels of stock are monitored at the right time in order not to miss stock or be too overstocked.

2. Why is stock management important?

For keeping balanced demand and supply, to minimise cost, improve customer service, and streamline the flow in operations.

3. How do we manage stock?

It’s organised systems of sorting, tracking, and reviewing inventory with well-trained teams and well-coordinated processes.

4. What are the different types of stock?

Types include raw materials, work in progress, finished goods, in transit goods, cycle inventory, anticipation inventory, MRO goods, decoupling goods, and buffer inventory.

5. What are the differences between stock control and stock management?

Stock control concerns maintaining stock levels, whereas stock management concerns the entire process from planning the goods to the movements of goods.