What is Lean Manufacturing?

Lean manufacturing is a management philosophy that is aimed at reducing waste and maximising customer value. The lean manufacturing meaning leans towards efficiency, productivity, and continuous improvement, ensuring companies deliver better quality while reducing costs and unnecessary resource usage effectively. Ultimately, knowing what is lean manufacturing is to understand it as a dynamic approach to aligning operations with customer needs.

Eliminating Waste, Elevating Value

The lean manufacturing process focuses on the identification and removal of waste that does not contain value to customers. Eliminating inefficiencies enables organisations to free up resources, enabling them to concentrate on the core tasks that add value to the business, which can increase performance and customer satisfaction and create a culture of sustainable and lean workflows.

Creating Quality Through Continuous Refinement

Organisations establish a permanent excellence based on refinement by employing lean manufacturing techniques like Kaizen, 5s and value stream mapping. These tools promote continual advances without massive transformations and disruptions to the prevailing status quo, although they lead to the development of better processes, reduced rework, and long-term competitiveness in ever-changing market situations.

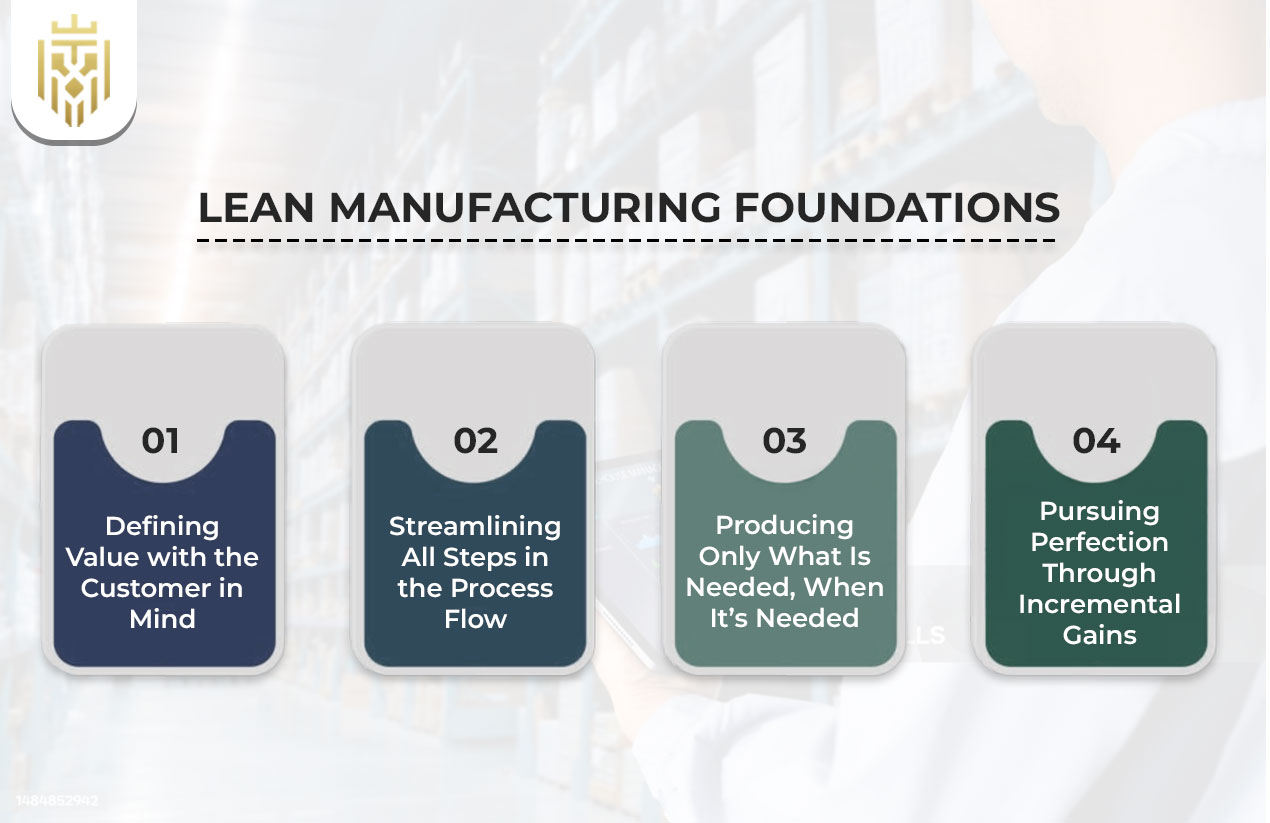

Lean Manufacturing Foundations

The five principles of lean manufacturing foundations are value, value streams, flow, pull, and perfection. These guiding factors make progress systematic. Every step aids waste prevention and assists organisations to adapt constantly, build resilience, and improve operational efficiency throughout their business model.

Defining Value with the Customer in Mind

Customer focus is core to lean manufacturing. A clear definition of value necessitates the alignment of business objectives with the expectations of customers, filtering out features and outcomes that are irrelevant. This practice provides a method of utilising resources in a meaningful way, which leads to higher satisfaction, loyalty, and a long-term competitive edge.

Streamlining All Steps in the Process Flow

The lean manufacturing process is about its smooth flow through each stage of operation. By eliminating bottlenecks and delays, companies achieve efficiency, shorten cycle times, and remain flexible. This principle not only improves the responsiveness of the supply chain but also ensures the delivery is on time and consistent at different customer locations.

Producing Only What Is Needed, When It’s Needed

One of the main principles of lean manufacturing is to create only what is necessary at the appropriate time. This reduces excess stock, eliminates waste, and maximises cash flow. These demand-based systems enable organisations to be competitive, responsive, and resilient in turbulent markets.

Pursuing Perfection Through Incremental Gains

The best results are achieved through minuscule but regular changes over time. The key lies in cultivating a mindset of incremental progress. Ongoing changes will enable companies to avoid stagnation, reinforce quality criteria, and create procedures that respond to customer needs as they change over time.

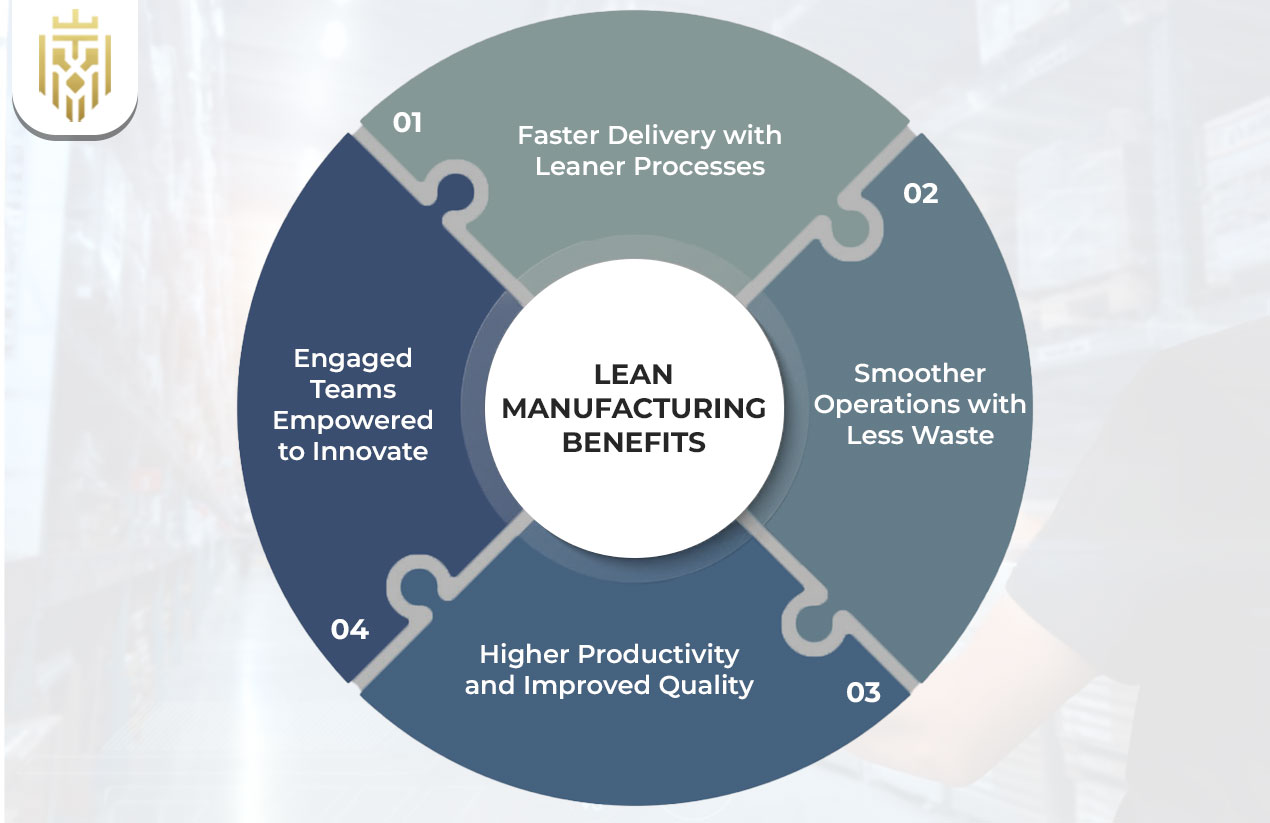

Lean Manufacturing Benefits

Legacy benefits of lean manufacturing go beyond cost-cutting. They promote innovation, agility, and resilience, building closer customer confidence. Companies that adopt lean can build scalable systems that respond swiftly to market dynamics and become competitive over the long term, posing a sustainable competitive advantage.

Faster Delivery with Leaner Processes

The implementation of lean manufacturing tools enables companies to optimise workflows and eliminate redundant processes that reduce the speed of delivery. Improved customer satisfaction is due to faster and more reliable operations that lower lead times. This responsiveness not only enhances the supply chains but also builds better market positioning in general.

Smoother Operations with Less Waste

Reducing waste facilitates smoother operations, which is a major concern of lean manufacturing. Organisations reduce unnecessary activities and streamline resources, leading to cost reduction and an increase in output. This transition leads to efficiency within departments, which puts less strain on systems but results in greater productivity levels continuously.

Higher Productivity and Improved Quality

The lean manufacturing process leads to businesses getting greater productivity through their ability to produce more products using fewer resources. This efficiency correlates with quality improvements, which is because lean prioritises doing things right on the first instance, with minimal defects, rework, and a significant increase in performance in organisations.

Engaged Teams Empowered to Innovate

Lean manufacturing also enables employees to play a positive role in innovation and gains. Involved teams learn how to solve problems, test new concepts, and reduce inefficiencies together. This empowerment develops responsibility and establishes a culture of trust, promoting creativity and maintaining long-term quality.

FAQs

1. What does lean manufacturing stand for?

Lean manufacturing refers to a methodical process of streamlining waste, increasing efficiency, and providing value. It makes organisations concentrate on vital processes only, establishing lean operations and sustainable competitive advantage.

2. Why focus on continuous improvement like Kaizen?

Kaizen is a process of continuous improvement through which teams will be empowered to make incremental improvements in their efficiency and quality. The culture generates adaptability, avoids stagnation, minimises costs, and maintains long-term operational excellence in lean cultures.

3. How does Kanban support lean production flows?

Kanban is used to facilitate lean manufacturing by making process flows visual, creating just-in-time production, minimising delays, and eliminating overproduction. It fosters flexibility, transparency and responsiveness in supply chains and engages resources to meet customer demand.

4. Why is a clean workspace vital in lean systems?

A clean workplace, which is enhanced through lean manufacturing tools such as 5S, increases safety, decreases errors, and improves efficiency. It boosts employee morale and facilitates seamless operations to maintain overall excellence in lean systems.

5. What does Total Productive Maintenance bring to the table?

Total Productive Maintenance (TPM) helps to increase equipment reliability by reducing breakdowns, enhancing safety and productivity. It allows employees to take care of machines and run operations in a proactive manner that guarantees streamlined processes, increased productivity, and continuous lean manufacturing output.