What is Inventory Replenishment?

Inventory replenishment refers to the act of replenishing products in order to ensure that stocks are available and that stock outs do not occur. It guarantees the free movement of inventory in the management process of distribution channel and fulfilling customer demand. The given approach is vital to the definition of distribution management and the efficiency of the supply chain.

How Inventory Replenishment Works?

Inventory replenishment operates to transfer the stock in storage or with the suppliers to the main picking locations to meet demand. Such an ongoing process improves distribution management strategy and balances supply and demand. It also makes the process within the distribution channel management system smooth to avoid any hindrance.

Why does Inventory Replenishment matter?

Inventory replenishment helps businesses to have the capacity of meeting customer orders as they come, avoiding the likelihood of backorders and overstocking. It is important to know what distribution management is, as it links the inventory plans with the effective channel and logistics plans, enhancing customer satisfaction.

Objectives of Inventory Replenishment

The objectives are to keep the optimum level of stocks, avoid stock outs and overstocking, lower cost, and make the products available as per the demand of the customers by adopting effective distribution management practices.

Preventing Overstocking

Avoiding overstocking implies maintaining the optimum stock levels to minimize the excessive storage costs. Here management distribution decisions help in making sure that items are only reordered when necessary. This will aid in simplifying operations and will contribute to more intelligent practices of distribution channel management that shuns waste.

Optimizing Stock Level

The stock maintenance can be optimised by ensuring that stocks are replenished in time and no unwarranted build-up is made. The given practice contributes to the increased effectiveness of a warehouse and facilitates the overall goals of distribution management. It is an aggressive plan which balances demand of customers with intelligent management of inventory and distribution channels.

Avoiding Stock outs

It is important to avoid stock outs in order to be able to meet customer orders within the required time. Inventory replenishment strategies and tools which businesses use to keep adequate stocks go hand-in-hand with distributions management principles. This will result in service improvement and lost sales will be avoided since products will be available.

Minimizing Cost

Replenishment assists companies to incur minimum costs by preventing overstocking and stock outs. Combining efficient distribution management methods, which are cost effective, and inventory control reduces holding costs. Also enhances efficiency of the management process of the distribution channel whilst maintenance of service levels are maintained.

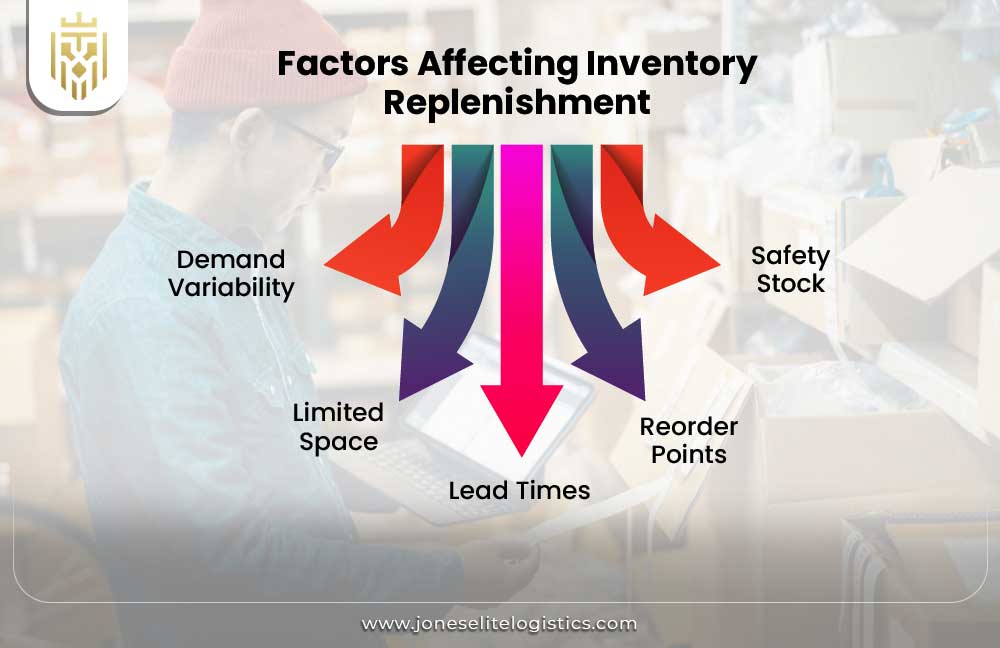

Factors Affecting Inventory Replenishment

The most important factors are the variability of demand, lead times, available storage space, the level of safety stock and effective forecasting. These determine replacement time, rate and general effectiveness of the process of managing the distribution channel.

Demand Variability

The variability of demand has a direct influence on the replenishment frequency of items. To handle this, then the businesses need to learn how to dynamically adapt their inventory strategies. Such decisions are closely linked with distribution management definition, which makes sure that they are ready even when the demand pattern changes.

Limited Space

Inventory planning and replenishment are challenged by limited space in the warehouse. Companies have to depend on effective distribution management and spatial arrangement to make good use of every inch. These strategies include clever stock turn and factoring in the movement of the products through the channels effectively.

Lead Times

Lead times influence the promptness with which replenishment of stock could be effected once ordered. Appropriate knowledge of the definition of management assists in the formation of the processes that factor in supplier schedules, transit times, and demand patterns and map them to timely planning of inventory and distribution management.

Reorder Points

Reorder points refer to levels at which new orders of inventory are activated. Identification of correct points is essential in good management of distribution channels. These are the levels that guarantee the availability of products, minimize carrying costs and are important in distribution management in balancing supply against demand.

Safety Stock

Safety stock prevents the uncertainties of demand or delays. It is imperative to its management to prevent stock outs and a fundamental principle in distribution management. When used in inventory planning, integrating it enhances resilience in business and ensures a smooth flow of products in channels.

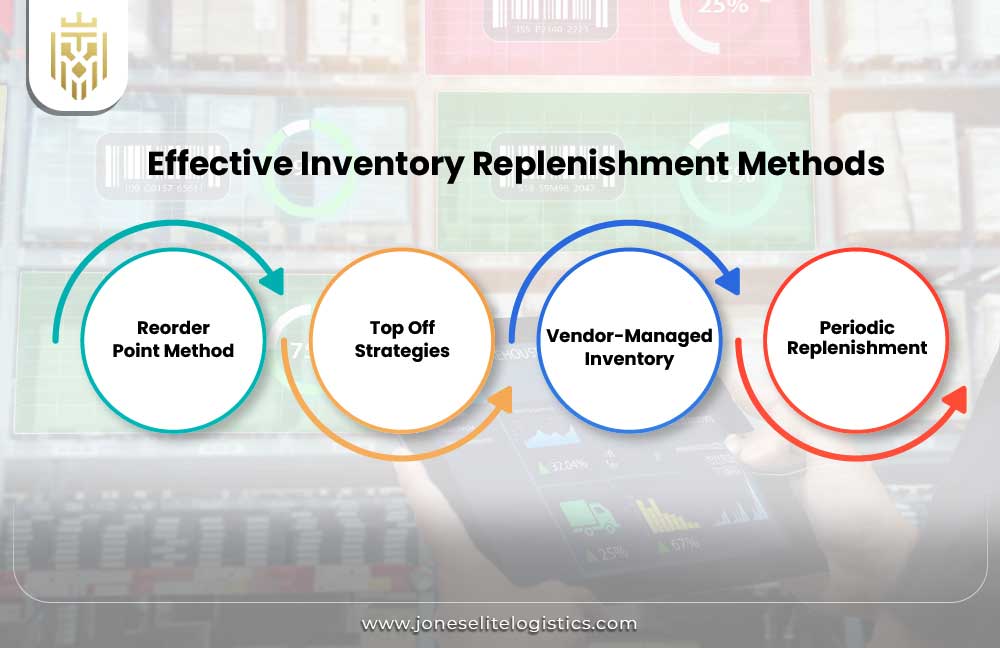

Effective Inventory Replenishment Methods

The most efficient of them are Reorder Point Method, Top-Off strategies, Vendor-Managed Inventory and Periodic Replenishment. These strategies guarantee on-time replenishment, price management, and efficient inventory movement via numerous channels.

Reorder Point Method

The Reorder Point technique assists in ensuring that stock is replenished in time by establishing certain inventory levels. This is a basic, though efficient plan, on which the distribution management counts, as the replenishment happens just in time to respond to the demand, without overwhelming the supply chain, or the storage.

Top Off Strategies

Top-off strategies restore the stock at the calm period to anticipate the wave of demands. It is an effective component of distribution channel management, and it improves the effectiveness of picks. It can be used with high volume products that must be available always in picking locations.

Vendor-Managed Inventory

Vendor-Managed Inventory allows the suppliers to do stock replenishment. This partnership enhances precision and saves expenditures. It falls in line with effective distribution management thinking, in that it lightens the load of the buyer, and uses the supplier knowledge to improve inventory and management distribution performance.

Periodic Replenishment

Periodic replenishment- In this method, inventory is replenished at pre-determined times. It is an easy method of planning and is applicable on items with steady demands. It follows coherent objectives of distribution management definition making the replenishment calculable and allowing the maintenance of operations within a controlled system.

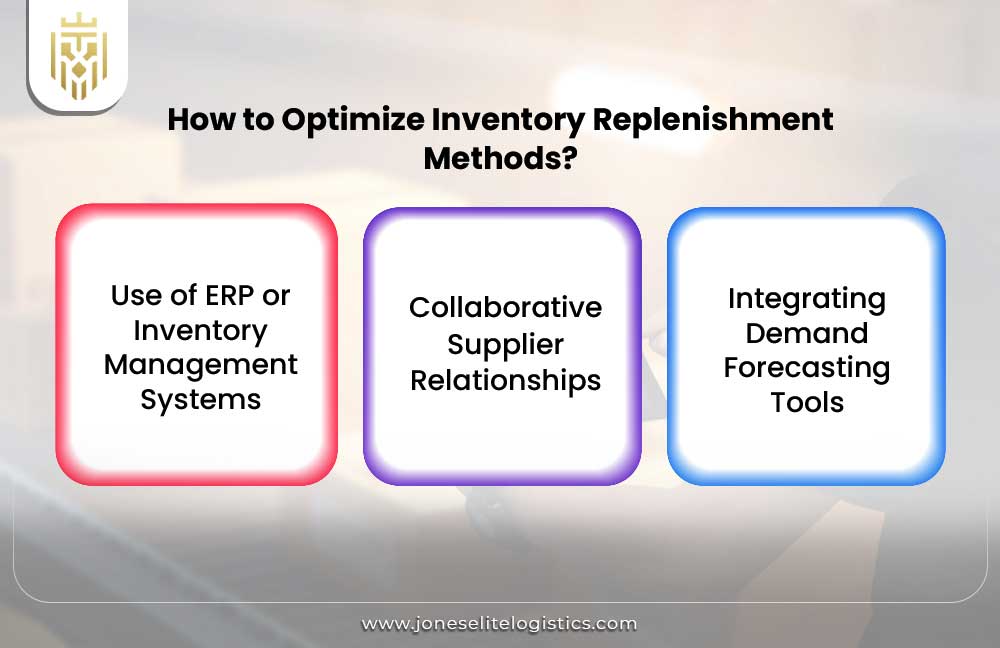

How to Optimize Inventory Replenishment Methods?

Optimization entails the utilization of ERP systems, creation of cooperative relations with suppliers and integration of demand forecasting tools. These plans enhance precision, lower the expenses and distribute the whole lot in a better manner to be sure of constant product availability and customer contentment.

Use of ERP or Inventory Management Systems

ERP systems place more emphasis on inventory monitoring, and automated re-ordering. These online technologies are in line with current distribution management trends, which offer visibility and effective management of stocks in real-time. The use of such technology aids in cost reduction and eases of operation through the channels of distribution.

Collaborative Supplier Relationships

Working with the suppliers enhances inventory planning by exchanging information and predictions. This kind of relationship enables effective distribution channel management through enhanced response to changes in the market. Companies that know how to collaborate with the suppliers earn the benefits of efficiency in the long run.

Integrating Demand Forecasting Tools

Demand can be predicted with the help of forecasting tools. These are the tools to harmonise the distribution management strategies with inventory. Predictive analytics reduces the element of surprise and improves the accuracy of replenishment to strengthen a smarter more proactive management distribution scheme throughout the supply chain.

FAQs

1) What is Inventory Replenishment?

Inventory replenishment refers to the act of replenishing products in order to ensure that stocks are available and that stock outs do not occur. It guarantees the free movement of inventory in the management process of distribution channel and fulfilling customer demand.

2) What are the objectives of Inventory Replenishment?

The objectives are to keep the optimum level of stocks, avoid stock outs and overstocking, lower cost, and make the products available as per the demand of the customers by adopting the effective distribution management practices.

3) What are the factors affecting Inventory Replenishment?

The most important factors are the variability of demand, lead times, available storage space, the level of safety stock and effective forecasting. These determine replacement time, rate and general effectiveness of the process of managing the distribution channel.

4) What are the effective Inventory Replenishment Methods?

The most efficient of them are Reorder Point Method, Top-Off strategies, Vendor-Managed Inventory and Periodic Replenishment. These strategies guarantee on-time replenishment, price management, and efficient inventory movement via numerous channels.