What Is Dunnage?

Dunnage is a protective material applied in securing cargo in transit. Dunnage avoids breakages, minimises the motion, and holds objects in a pack. Dunnage may be made of plastics, paper, foam, or dunnage wood according to shipping and item sensitivity.

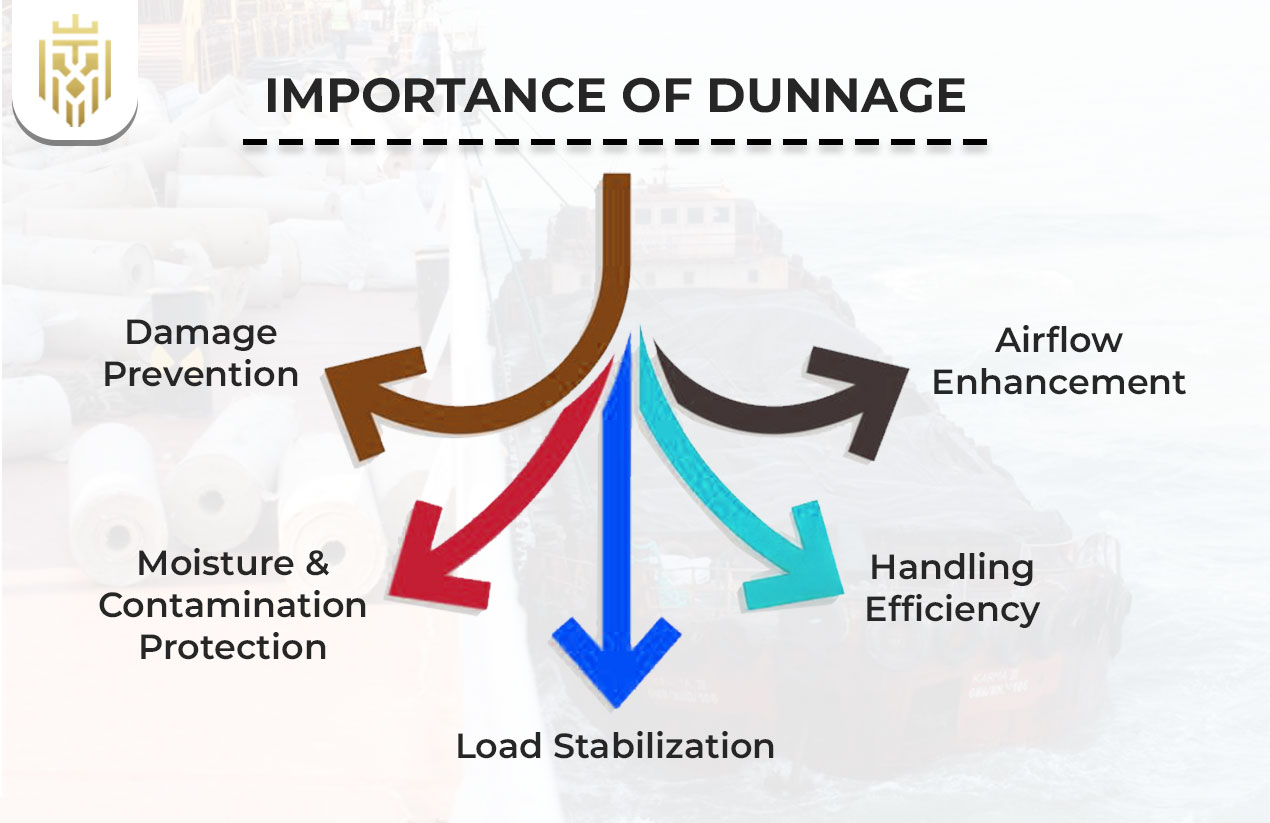

What is the importance of dunnage?

The importance of dunnage in the shipment of goods is that one needs to understand what dunnage is, as it serves as a cushion against impact, moisture, and shifting. Dunnage material not only preserves goods but also enhances cargo handling and cost-effectiveness in various industries, ensuring that cargo reaches the destination safely and intact.

Damage Prevention

Preventing physical damage to goods is one of the main purposes of dunnage. It takes up shocks, absorbs impacts, and keeps things still in packaging. The appropriate material of dunnage incredibly lowers the possibility of breakage in the course of transportation over lengthy or bumpy routes.

Moisture & Contamination Protection

Some dunnage materials can serve as a barrier to both moisture and contaminants. Dunnage is specifically useful to prevent pounding on perishables or electronics, in which mould, rust, or exposure to chemicals can be an issue. What does dunnage mean? It makes a good covert deterrent against environmental losses through shipping that spoils the product.

Load Stabilisation

The stabilisation of cargo loads is an important advantage of the use of dunnage. Correct load support helps items to stand steady, minimises their shifting, and lowers vibrations during transportation. Some of the dunnage, like wood plastic composite materials, are both tough and flexible; hence, they are suitable for load securing.

Handling Efficiency

Proper dunnage ensures that material handling is faster and safer. The handlers can handle packages more efficiently because they tend to organise their cargo in an equal manner and avoid awkward loads. Different kinds of dunnage also help avoid damage when the load is loaded and offloaded either by a forklift or manually positioned.

Airflow Enhancement

In certain jobs, such as perishable transport, dunnage helps move air among loaded products. Ventilation enables the preservation of the quality of goods and the avoidance of heating. Proper circulation is maintained by the right positioning of dunnage such as ventilated crates or spacers, especially when it comes to produce and temperature-sensitive materials.

Common Types of Dunnage

Dunnage comes in solid plastic, bubble wrap & air pillows, packing peanuts & foam inserts, kraft or corrugated paper, wood & cribbing, steel dunnage, dunnage bags (airbags), and custom foam/plastic forms, depending on the nature of the goods to be shipped in various transport modes. The dunnage material varies depending on the nature of the cargo, whether it is lightweight, rigid, or reusable. The items include dunnage wood, air-filled bags, and engineered foams.

Solid Plastic

Flexible dunnage is made of solid plastic, which is durable, reusable, and not affected by water. It is referred to as a common application in industrial and automotive shipping. This dunnage substance can hold heavy stuff without breaking. The use of plastic is favoured over wood-plastic blends since it has a long life span and can be cleaned in logistics chains.

Bubble Wrap & Air Pillows

These dunnage cushioning are suitable for light and fragile commodities. The packaging made of air fits the products to minimise shock and vibration. They are ordinary in e-commerce and one of the cheapest features when getting to learn various packaging techniques to be used when transporting non-industrial goods.

Packing Peanuts & Foam Inserts

Packing peanuts & foam inserts are utilised principally in sensitive electronics and glassware, as they adapt to strangely shaped products. They are not environmentally friendly, but they are good shock absorbers. Other firms look into biodegradable alternatives to dunnage material used to avoid waste and, at the same time, have internal product support and balance.

Kraft or Corrugated Paper

Paper dunnage is flexible and renewable. They seal spaces, envelope products, and inhibit mobility. Due to being environment-friendly, they are regarded as a cheap and green alternative. Kraft papers are ideal in retail and food packaging of goods that do not require heavy shipping.

Wood & Cribbing

Heavy-duty support and stabilisation are carried out through the use of dunnage wood. Wood cribbing can be used in the transportation of machinery or bulk goods to add structural integrity. It is heavy, but it is commonly used in rugged cargo environments where other types of dunnage materials do not provide enough support.

Steel Dunnage

Steel dunnage are rare yet essential in heavy equipment logistics. They have unrivalled overload capacity on loads, most notably rail or industrial freight. They are recyclable and applicable in various cycles, especially where high-weight load-bearing is a key concern.

Dunnage Bags (Airbags)

Dunnage bags are inflatable devices (usually airbags) installed between other items to avoid the shifting of cargo. These are flexible and reusable and can be shipped through pallets or containers. They are lightweight and reliable, with flexible solutions in various kinds of industries that demand tight cargo stabilisation.

Custom Foam/Plastic Forms

Dunnage material solutions are created in custom foams, and foams are best suited to delicate or precision components. These are customised foam or moulded plastic trays, which hold goods strongly. Such dunnage are extensively used in electronics and medical shipments to ensure maximum safety, and they also allow no internal movement within the cartons.

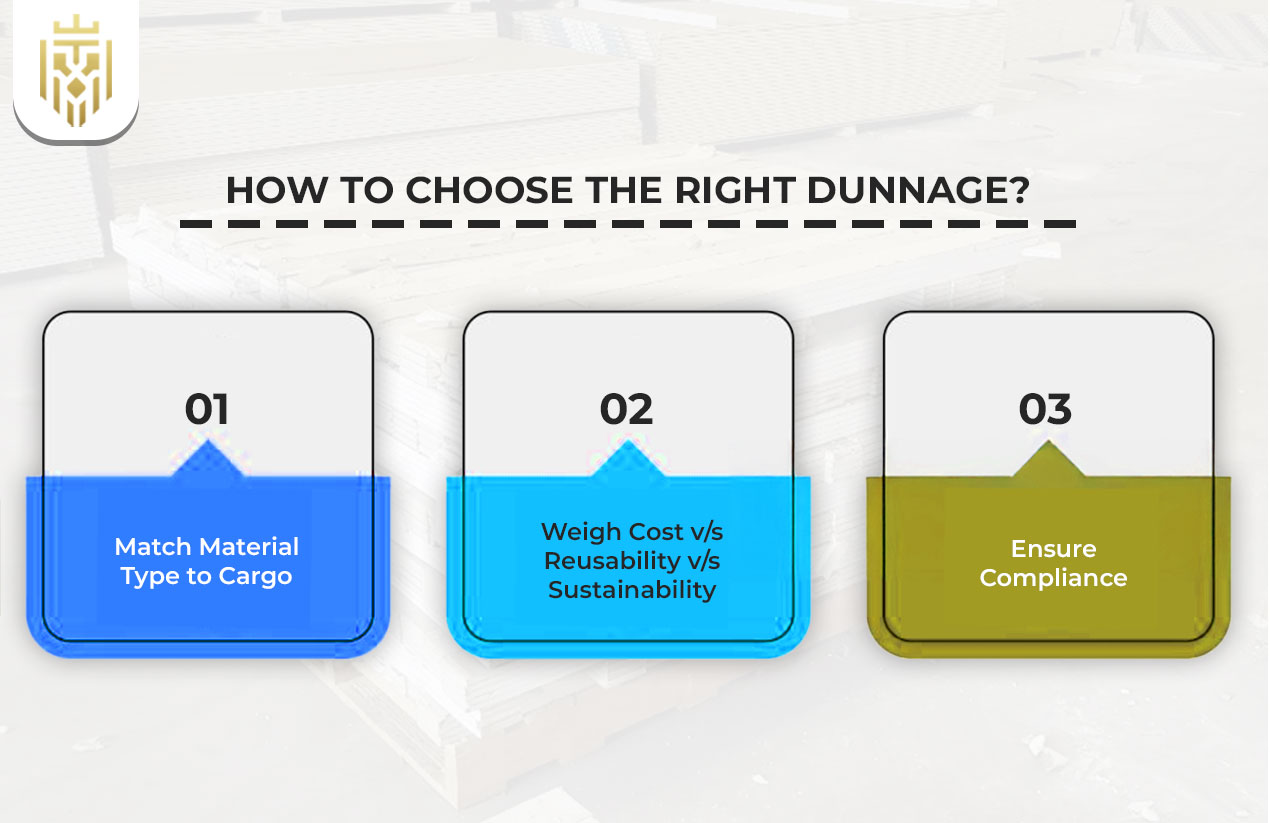

How to Choose the Right Dunnage?

To pick the right dunnage, it is necessary to take into consideration the weight, fragility, moisture sensitivity, and transport type. It is fundamental to learn about various profiles of cargo. The perfect way out will be taking the appropriate material applied with durability and practicality to suit shipping objectives and economy.

Match Material Type to Cargo

By making sure that you use the dunnage material that fits your cargo, you will have safety and efficiency. Lightweight items might just have to use foam or bubble wrap, but bulk items might have to use either dunnage wood or steel. Select the right type of this regarding the product’s stability and handling requirements.

Weigh Cost vs. Reusability vs. Sustainability

Cheap dunnage is not necessarily cheap in terms of initial cost. Other materials, such as solid plastic or wood plastic, should be reused in the long run, resulting in economic benefits. The issue of sustainability, cost, and reuse potential is important in contemporary buying and warehousing plans that are responsible towards packaging.

Ensure Compliance

Cheap dunnage is not necessarily cheap in terms of initial cost. Other materials, such as solid plastic or wood plastic, should be reused in the long run, resulting in economic benefits. The issue of sustainability, cost, and reuse potential is important in contemporary buying and warehousing plans that are responsible towards packaging.

Best Practices for Dunnage Use

The way to use dunnage starts with having the knowledge of the packaging layout. Use materials to strategic advantage to restrict movement of the products, maximise protection, and optimally utilise the space. Such inspection of various kinds of materials is necessary to make every shipment accurate and careful in order to deliver it safely.

Right Packaging for Right Space

It should not be over- or under-filled. Good dunnage fits well to the dimensions of the package and does not leave space. Depending on the size and weight of the item, use foam, air bags, or dunnage wood. Proper fit minimises handling damage and distorts cargo of different sizes and shipping freight to the fullest.

Distribute Cushioning

Supplying the package with a uniform distribution of dunnage material will stabilise the product and absorb shock. Asymmetry will lead to tipping or its breaking because even cushioning may result in imbalances. Education on the available materials can also be used to distribute the protection in every nook and corner when shipping sensitive or vulnerable products.

Inspect Dunnage

Verify the dunnage used (check all dunnage) before use to see moisture, wear, or breakage. Goods cannot be well-protected with damaged materials. This is an inspection measure whereby your cargo is not threatened during its transportation, especially under the employment of used plastic, foam, or dunnage wood.

Store Supplies Properly

Dunnage kept in dry and clean sections is retained in good condition. Dunnage material can be imperilled by moisture and contamination (such as paper or wood-based types). Movement of inventory and non-storage of materials on the floor is essential in structuring them to remain reliable and strong to be used in the future.

Training Staff

Educate employees on the proper use of dunnage at every department. Knowing what dunnage is and how it increases shipping safety will result in a reduced number of damaged shipments and decreased costs. Waste and error can be severely cut down by keeping the staff trained to spot suitable material used.

Applications by Industry

Dunnage is used in various industries, namely, the consumer electronics industry and the food logistics industry. The different sectors need special materials and layouts. Having awareness of the various requirements in the industries guarantees that appropriate dunnage is selected in order to preserve the items in the manufacturing and transportation process.

E-commerce & Fragile Goods

In e-commerce logistics, the dunnage material, such as inserted foam, air pillows, or paper, is used to avoid damage during last-mile delivery. They are perfect for electronic goods, cosmetics, and collectibles. Learning the answer to the question of ‘what is dunnage?’ enables businesspeople to wrap up their goods properly and prevent high rates of returns due to shipping.

Heavy Machinery & Industrial Equipment

Bulk parts such as engines or turbines require robust dunnage wood or steel braces. These dunnages cushion them and do not allow movement on trailers or containers. Their ability to be reused and used safely makes them necessary in achieving and meeting the delivery in large-scale industrial logistics.

Perishables & Temperature-Sensitive Cargo

Airflow is essential in the case of perishables. Temperature stability is ensured by the use of dunnage that improves ventilation (rather than a solid pallet or crate) or pallets or crates with slats that allow movement of air. Such dunnage materials restrict the accumulation of moisture, too, preventing spoilage or destruction of items by inefficient shipping conditions.

Environmental & Cost Considerations

Sustainable shipping includes choosing eco-friendly types of packing material, such as recyclable foam or paper that is biodegradable. Companies are also giving way to reusable options to lower waste levels in packaging. Ensuring knowledge of alternative options helps to increase the environmental contribution and achieve the green logistics objectives without increasing expenditures.

Reusable Options

Containers are made out of plastic, wood, plastic pallets, and steel dunnage and are constructed on a reusable basis. They have a higher price tag in the short term because they have long-term savings and environmental advantages. Using reusable material also falls within the global initiatives of a greener supply chain and packaging business.

Eco-Friendly Materials

New environmentally sensitive companies are opting out of dunnage material that is sourced using recyclable or biodegradable material. Synthetics are replaced by the use of paper and corrugated fibre, as well as starch-based inserts. Such alternatives enable sustainability in various industries with the desire to achieve decreased carbon and landfill prints.

Bulk Buying

Buying dunnage in bulk will lower the costs per unit and guarantee the availability of the material. Better planning can also be done, as there is bulk buying to be done even in cases of various types of cargo. Businesses that deal with large volumes in terms of shipping reduce delays and consolidate protective packaging.

FAQs

1) What is dunnage?

Dunnage is the protective material in the shipping of goods used to stabilise and swaddle the cargo. It helps in preserving goods of the transportation process against shifting, impact, or exposure to moisture.

2) Why use dunnage?

Dunnage prevents damage to cargo and promotes handling efficiency and safety. This makes goods reach their destinations intact, making operations within the supply chains less expensive in time and money because of the reduction of losses and claims.

3) What is reusable dunnage?

Dunnage is said to be reusable, and this will comprise long-lasting materials, such as wood, plastic, or solid forms of plastic. It is economical in the long term, minimises waste, and is frequently applied in automotive and industrial technologies.

4) How to choose the right dunnage?

Take into consideration the material used, the fragility of the product, the method of transport, and nature. Consider alternative forms that include foam, dunnage wood, or airbags in the process of evaluating them so that they fit well with your cargo considerations, sustainability interests, and handling conditions.

5) What happens if I skip using dunnage?

Failure to use dunnage exposes the cargo to the danger of shifting, breaking, or contamination. It causes financial losses, safety hazards, and weak customer satisfaction. Items as strong as they are will get broken without good stabilisation in transit.