What is Demand Planning?

Demand planning is a standalone function of supply chain planning, which deals with forecasting and estimating the quantity and timing of customer demand. Demand planning helps organisations match supply, distribution and stocks to the requirements of their clients hence cutting costs and enhancing organizational performance.

-

How does Demand Planning work?

Demand planning requires historical data, market knowledge as well as statistics software tools to forecast what might be needed by consumers in the future. The typical and valuable advantage of this demand planning method is that a business can make sure that inventory, production and others related resources are optimized and appropriately managed in a particular period, in order that the business is capable of timely and accurately detecting changes on the market and people’s shopping behavior.

Why is Demand Planning important?

Demand planning and forecasting help in managing inventory, operational expenses, and product availability for the consumers. It enhances customer satisfaction whereby businesses make certain that the right products in the right quantity and at the right place are delivered to the customers at the right time.

-

What is The Difference between Demand Planning and Demand Forecasting?

Demand forecasting presupposes what customers will have or want in future, demand planning then elaborates how it will meet that forecast. It is quite obvious that demand planning without execution is nothing but a sophisticated wish list. It transforms expectations of the company into a set of tangible, doable activities that effectively take into consideration the resources that will be used and the capacity of the supply chain to deliver on the set goals.

-

How Demand Planning Can Improve the Supply Chain?

Demand planning improves the supply chain by reducing the cases of stockouts and overstocking. Optimizations in inventory, production and delivery leads to efficient control on the cost and gets an effective result to provide products where they are required by the customers on time.

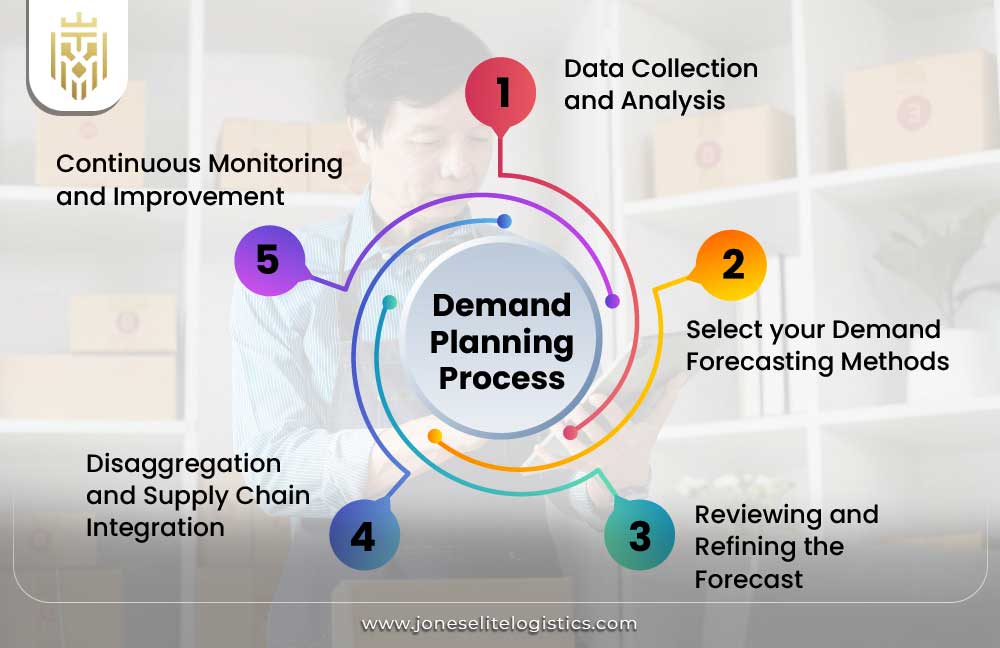

Demand Planning Process

Demands planning includes data collection and analysis, method selection, refinement steps, and integration of the supply chain and ongoing refinement. The following are areas where it helps to ensure that demand matches operation and inventory planning.

-

Data Collection and Analysis

Gathering and analysing data are the groundwork for demand planning and are essential to its overall process. It entails collection of information from both internal (like ERP or CRM) and external databases (like market research reports), analysis of the trends and the use of statistical methods like regression and time-series analysis. They are all important because they help companies to make the right prediction and enhance their planning.

-

Select your Demand Forecasting Methods

The identification of the most suitable forecasting method between qualitative and quantitative methods or a combination of both is critical when in the process of demand planning and forecasting. Based on availability of data and the type of product, organizations choose either of the two to make forecasts as accurate as possible for the overall supply chain planning.

-

Reviewing and Refining the Forecast

Revising and fine-tuning forecasts enhance the predictability of those plans. Through the fine tuning of models with real-time results, and new data in response to actual demand, businesses enable accurate demand planning which maintains an organization’s demand profiles with customer demand fundamentals, as well as keeping an organization’s supply chain flexible.

-

Disaggregation and Supply Chain Integration

Disaggregation divides forecasts into smaller parts such as geographic locations of stores, or different items of stock-keeping units. This should be integrated with the supply chain so as to align all functions within procurement, manufacturing, and distribution with the demand planning activity in order to minimize configuration and service gaps.

-

Continuous Monitoring and Improvement

Planning as an activity has to be an on-going process that has to be reviewed from time to time. In this case, there is a pattern of comparing the forecasted demand with the actual demand in order to rectify discrepancies. It further maintains the continuous loop of demand planning as a way of keeping up with the fast and ever-changing supply chain environment.

Elements of Demand Planning

These components are product portfolio management, statistical forecasting, trade promotion management, and demand sensing. Each of these components help in enhancing the forecast accuracy, inventory management, business with operations in line with demand patterns.

-

Product Portfolio Management

It is important to understand product life cycles in order to be able to come up with a good demand plan for their products. Products are differentiated and they call for different patterns of demand. These variations help particularly in the actualization of effective stock management, especially when dealing with new products or variations in the patronage of related products.

-

Demand Sensing

Demand planning depends on demand sensing, which translates into the signals that are being received from the sales and the markets. Forecasting assists companies to give timely responses to the changing demands hence flexibility and responsiveness to the market is enhanced.

-

Statistical Forecasting

Statistics is one of the most used approaches in demand planning and forecasting field. They use data collected in the past to estimate the future one and enhance the forecast as adjusting supply according to the indicated demand results in better utilization of resources.

-

Trade Promotion Management

Trade promotions influence buying habits among consumers. In demand planning, companies or organizations are in a position to evaluate the effects of a discount or of a campaign. Managing trade promotions means that sales forecasts that incorporate the effects of the promotion match the organization’s capacity to prepare for sales promotions.

Application of Demand Planning

Some of the typical use cases of demand planning include the use of Artificial Intelligence and machine learning, cloud based collaboration platforms and tools, and use of predictive analysis. They also support supply chain planning, better prediction, and enable companies to cover shifts in consumer behaviour and other supply chain dynamics more quickly and effectively.

-

AI & Machine Learning Integration

The application of AI and ML in demand planning improves the reliability of the forecaster and flexibility. These technologies can identify shifts in trends faster and also can help the organizations maintain a more efficient inventory hence reducing wastage while at the same time ensuring that supply chain adapts to real-time changes.

-

Cloud-Based Collaborative Platforms

Cloud-based solutions can be very effective in collaboration of demand planning by providing updated information. They combine analytical methods and data of social aspects to optimize the supply chain management and align its processes with other organizational functions, such as marketing, logistics, or sales.

-

Scenario Planning and Predictive Analytics

The change in demand is forecasted by employing the use of predictive analytics and; scenario planning is used to ensure that the businesses are prepared. Such tools assist the organizations within the demand management process to develop responsive plans for dealing with the vagaries and make the best supply-chain decisions.

-

Customer-Centric Models

Customer-orientated demand planning aims at identifying what clients need and when and how often they require it. This not only increases the accessibility of the product, decreases overstocking, and optimizes the SCM to deliver customer satisfaction effectively and efficiently.

FAQs

1.What is a demand planning process?

A demand planning process means the set of procedures which are aimed to create the optimistic, pessimistic or realistic forecast demands from the customers. This links directly with the supply chain planning to aim for better business procedures and services.

2.What is Demand Planning?

Demand planning is a standalone function of supply chain planning, which deals with forecasting and estimating the quantity and timing of customer demand. Demand planning helps organisations match supply, distribution and stocks to the requirements of their clients hence cutting costs and enhancing organizational performance.

3.How does Demand Planning work?

Demand planning involves using recorded data, market trends, and even the general environment to predict future demands. This helps in controlling inventory, production, and resources so that the companies can effectively fulfill customer requirements and avoid wastage.

4.What is the difference between Demand Planning and Demand Forecasting?

Demand forecasting refers to the anticipation of future demand, while demand planning leverages those anticipated demands to help develop a course of action. While forecasting answers what questions, planning helps to answer how questions – matching the expectations with capabilities and preparedness throughout the planning process.