What is Container Logistics?

Container logistics is the transport and management of goods as standardised shipping containers over the supply chain. This includes the planning, handling, storing, and transporting of these containers across the modalities of road, rail, and sea. With this method, logistics providers ensure the movement of cargo through domestic and international routes in a highly efficient, safe, and scalable way.

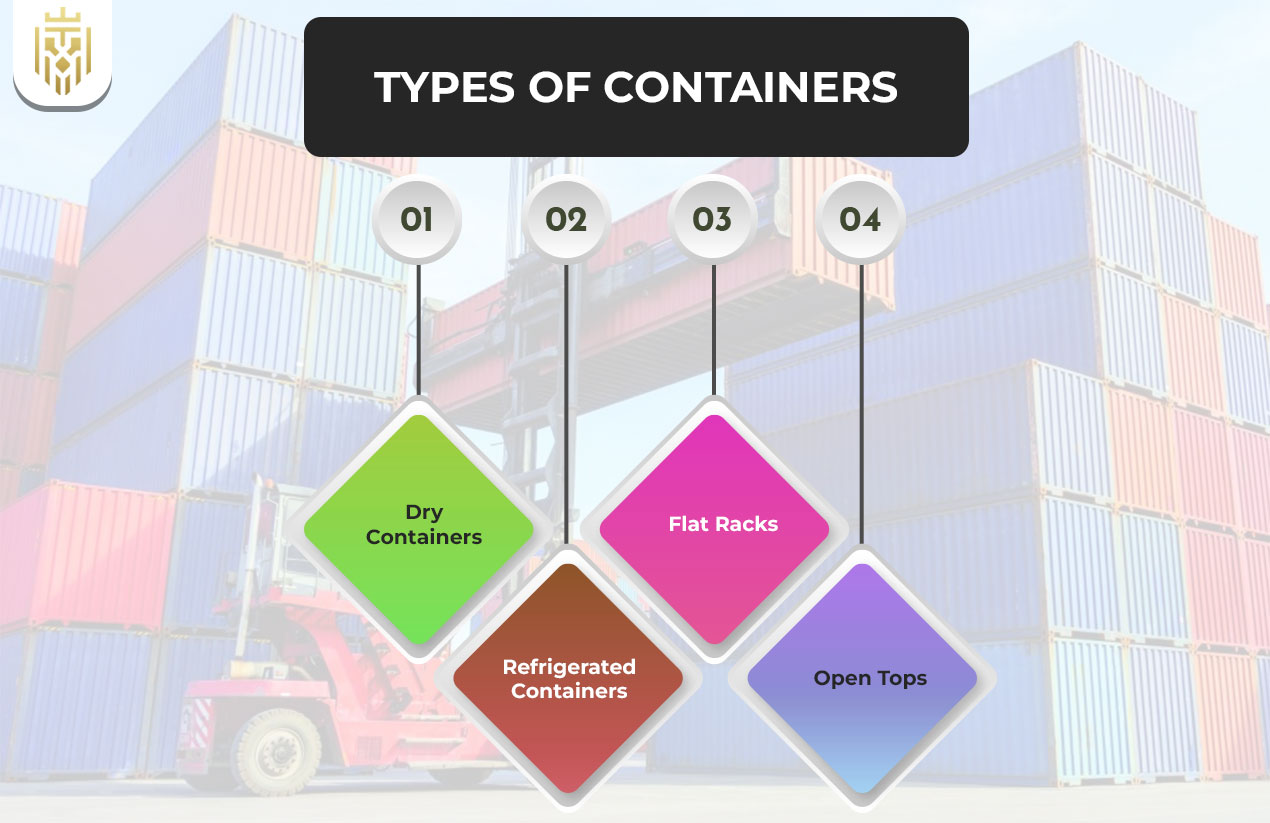

Types of Containers

There are several types of containers used in logistics, each designed for specific cargo requirements and transport conditions.

-

Dry Containers

Most common containers are used in general freight, manufactured goods, textiles, and electronics transportation. Dry containers are in standard sizes of interior space and sealed from weather elements.

-

Refrigerated Containers

These containers, also called reefers, undertake temperature management and serve for perishable food, pharmaceuticals, and chemicals. They maintain uniform temperatures throughout the voyage.

-

Flat Racks

Flat rack containers are intended for oversized or weighty cargo, which does not fit into standard containers. They have collapsible sides to offer flexibility in loading and unloading heavy machinery or equipment.

-

Open Tops

This is ideal for the transportation of cargo that is too high to pass through a door if a standard container is used. The open top is covered with a removable tarpaulin. Hence, it is used to transport large or awkwardly shaped items.

How did Containers Revolutionised the Logistics Industry?

The introduction of container logistics transformed the global supply chain by standardising transport units and reducing manual handling. It improved cargo safety, shortened transit times, and simplified intermodal transfers across different transport modes.

-

Container Logistics Process Flow

Each container shipment follows a detailed process to ensure timely and secure delivery.

-

Booking & Planning

The conclusive point at which the actual process of shipment booking and route planning occurs. Thorough planning guarantees the availability of space plus efficient scheduling.

-

Container Stuffing

Loading the products into the containers in such a way as to maximise available space and damage during transit. The documentation is also done at this stage.

Inland Transportation

Containers are transported from shipper sites to the port by truck or rail; timely inland movement supports an on-schedule departure of the vessels.

-

Port Handling

At the port, the containers are inspected, and then undergo documentation checks before being loaded onto the vessels. It helps in the reduction of dwell time.

-

Ocean Transit

Transporting containers across the seas. Real-time monitoring of their movement and state is possible during transit.

-

Destination Port Operation

They are offloaded and cleared at the destination port and ready for inland transportation.

-

Final Delivery

Containers are moved from the port to the consignee’s warehouse or distribution centre as per the delivery plan.

-

Container Return or Reuse

Empty containers are either returned back to their origin or repositioned depending on availability and demand for shipment purposes.

Technology’s Role in Smarter Container Logistics

Modern logistics companies use advanced tools and platforms to make container operations faster, more accurate, and data-driven.

-

Electronic Data Interchange

By bridging between stakeholders, processes such as booking or customs clearance and documentation are sped up.

-

Internet of Things

These activities include the establishment of sensors in containers that provide real-time information on location, temperature, and condition, thus increasing visibility and control.

-

Digital Twins

Digital replicas of physical containers help monitor container health, predict maintenance needs, and simulate different operational scenarios.

-

Transportation Management Systems

Transportation management systems automatically plan routes, select carriers, and track performance, resulting in better decision-making and cost control.

Challenges in Container Logistics

Despite its efficiency, container logistics faces ongoing operational and strategic challenges.

-

Supply Chain Disruptions

Occasional severe and unexpected hitches, such as geopolitical tensions, strikes, or natural calamities, disrupt the movement of containers and delay shipments.

-

Port Congestion

Congestion is created in major ports due to high volumes of cargo and limitations in handling capacity, negatively affecting the timeliness of delivery.

-

Rising Operational Costs

The increase in fuel, handling, and maintenance costs is a growing concern affecting the operational budgets of logistics.

-

Empty Container Repositioning

Balancing container supply between the regions remains a problem. Empty repositioning of containers incurs extra costs.

FAQs

1) What is container logistics?

Container logistics refers to the management and movement of goods within standard shipping containers through road, rail and sea networks.

2) What types of containers are used in logistics?

Commonly-usage would be dry containers, refrigerated containers, flat racks and open tops.

3) How can technology improve container logistics?

Technology enhances activities for better tracking, communications, and predictions and increases operational efficiencies through automation and real-time data.

4) Why are containers important in logistics?

Containers make standardised handling of cargo, increase better safety and performance, short run timings, and ease interchange of transporting modes.