Overview of The Supply Chain

The term supply chain describes a group of companies, resources and operations working together to supply goods. When supply chain management is effective, everything from sourcing materials to delivering them works well. Working in real time provides the supply chain with the data it requires and encourages more effective partnership.

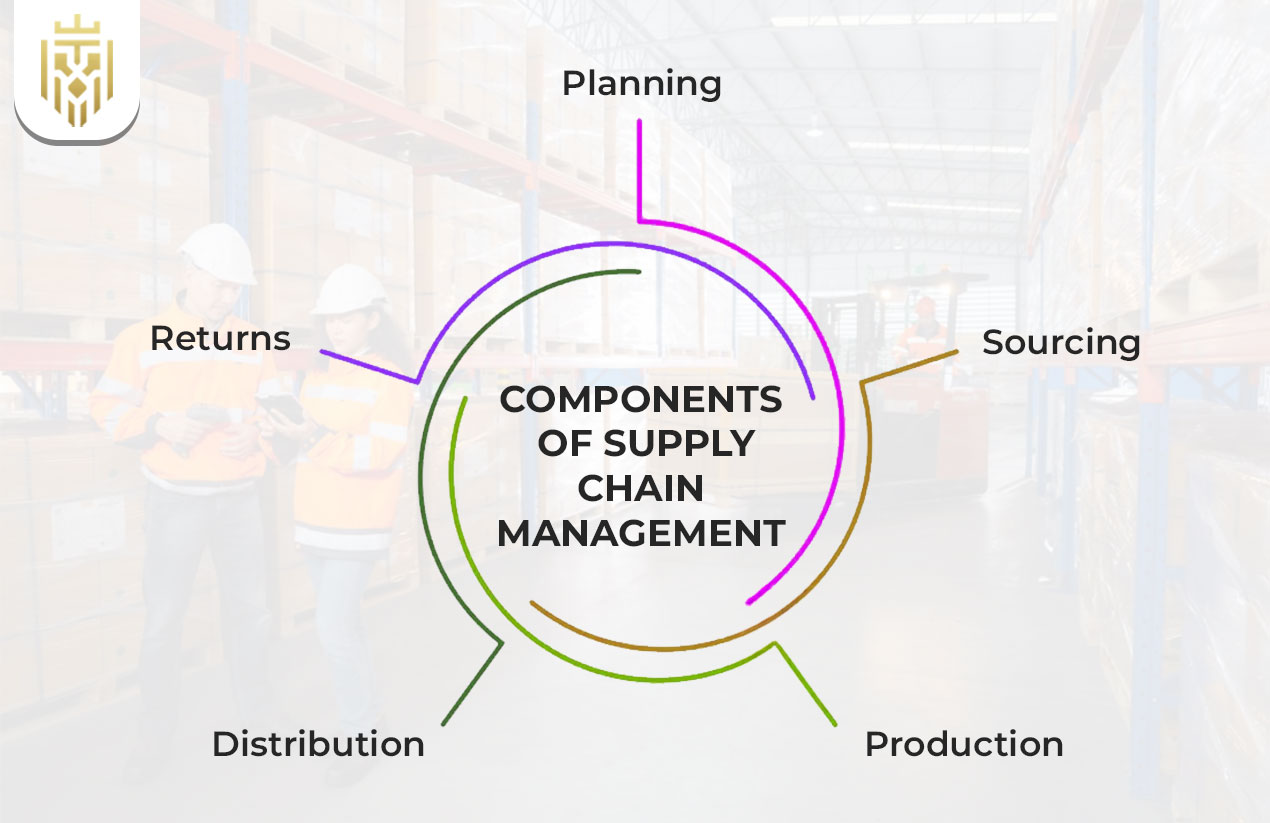

Components of Supply Chain Management

Supply Chain Management covers different functions such as planning, supporting, producing, moving and handling returns. These factors make communication easier, improve how operations function and support success in the supply chain by encouraging coordinated decision-making.

Planning

When planning in supply chain management, companies forecast demand, control inventory and make production schedules. They help information pass between departments and partners without interruption. Planning plays a key role in making a successful supply chain, as it helps unite all supply chain operations.

Sourcing

By sourcing, companies try to ensure they work with manufacturers that provide good quality products. Making this supply chain decision makes the organization more resilient, less exposed to risk and encourages better relationships with suppliers. When design strategy and clear buying processes are applied, sourcing helps supply chains stay stable and cost-efficient.

Production

Production transforms raw materials into finished products through manufacturing, assembly, and packaging. It plays an essential role in supply chain design, helping products meet what is expected of them. Good production planning is necessary for an effective supply chain and helps lower waste in every stage of decision making.

Distribution

Getting goods out to customers from suppliers is made possible by distribution. A company needs to manage logistics, warehouse storage and transportation for it to work. Proper distribution raises customer happiness, helps with design and organises flow information to succeed in the entire supply chain.

Returns

Handling customer returns, stocking back items and providing refunds make up returns or reverse logistics. It is important to supply chain management because it modifies brand loyalty and the efficiency of operating systems. Return procedures that are efficient keep the cost of the supply chain low and see that information flows smoothly backward.

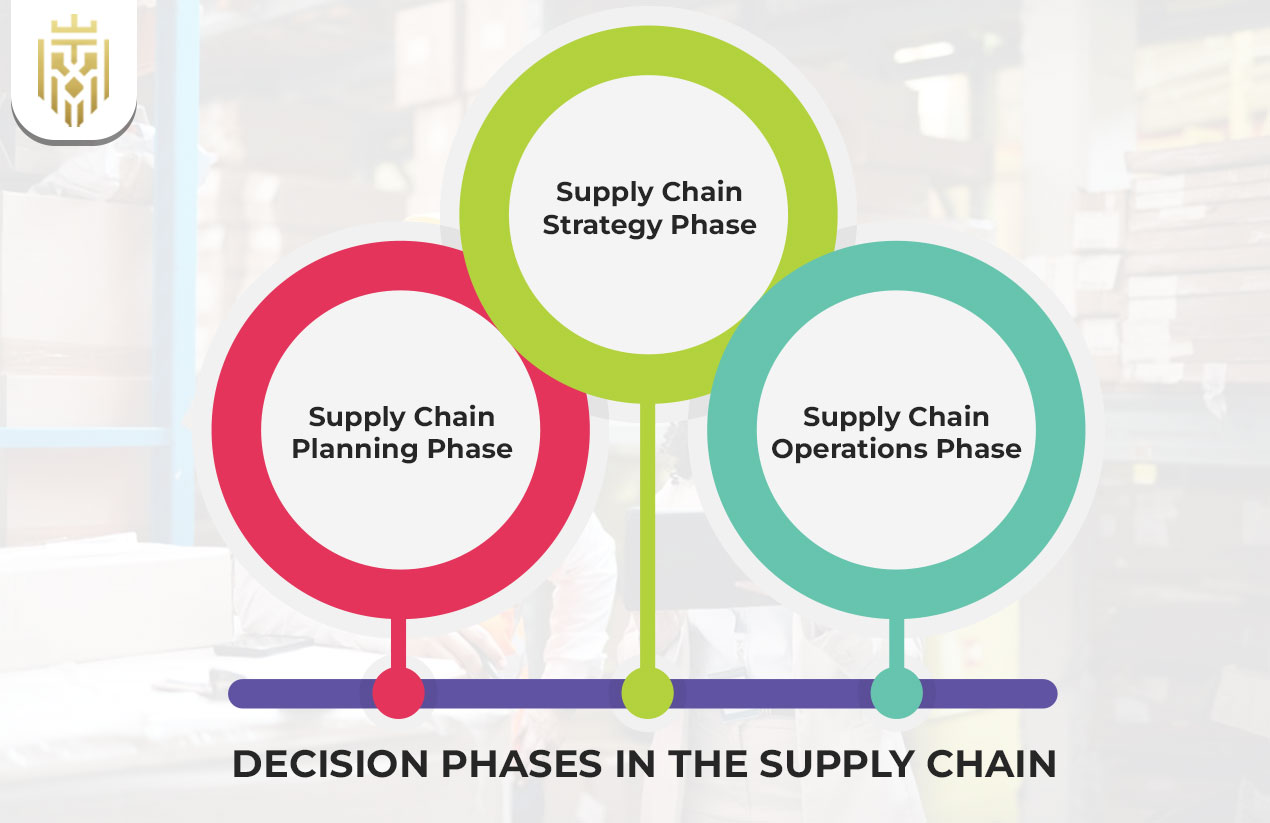

What are the Decision Phases in the Supply Chain?

During supply chain processes, there are different stages, each targeting its own focus. Strategy, planning and operations are the three phases in the decision process of a supply chain. Having these supply chain decision layers helps the structure remain aligned in the long run, stable in the medium term and responds quickly in the short term.

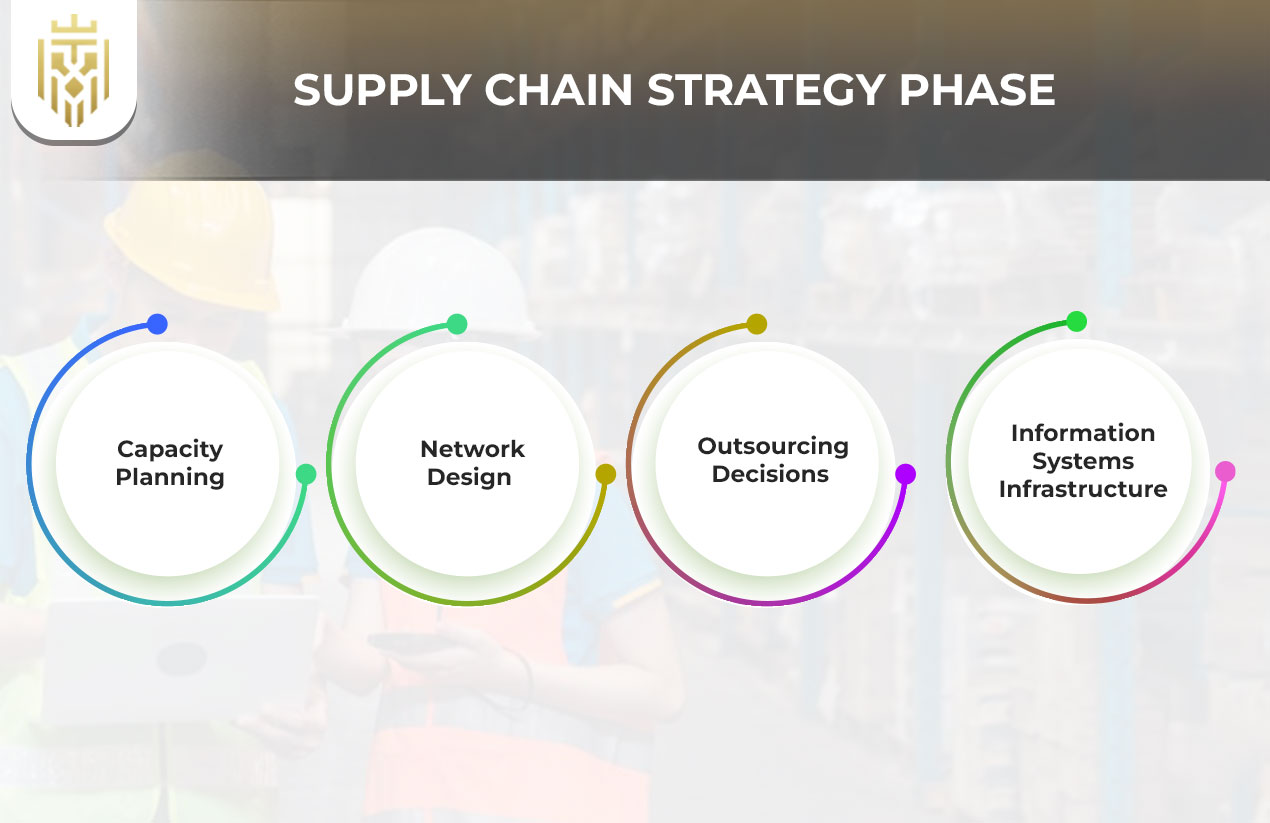

Supply Chain Strategy Phase

The supply chain strategy phase starts with the most important structural planning. Where a facility will be placed, how many items it will hold and the transportation methods chosen are important foundation points in supply chain design. A good strategy makes it easy to manage data and enables long-term success of the supply chain.

Capacity Planning

Capacity planning is used to determine how many resources are needed and when they should be made available, so organizations do not encounter either shortages or overcapacity. When making decisions in the supply chain, it helps determine how future operations will be run. A successful supply chain results from planning that ensures production is optimised and connected to the general goals of the design strategy.

Network Design

To design a network, managers organize facilities, routes for transport and regions where inventory will be held. By using such a supply chain option, quality information about products and services flows efficiently. It is a vital task in designing supply chains, as it builds the foundation for a thriving supply chain structure.

Outsourcing Decisions

With outsourcing, businesses find and agree upon vendors to complete specific services. Decisions in the supply chain shape how much it will cost, how easily it can adapt and how well it operates. An effective design process reviews the pros and cons of outsourcing which makes it crucial in different stages of planning the supply chain.

Information Systems Infrastructure

Modern supply chain management depends on technology, most of all during the strategy phase. It ensures that demand forecasting, sourcing and collaboration run as needed. Allowing for better flow of data and better judgment, integrated systems rely on IT infrastructure in the decision-making part of the manufacturing chain.

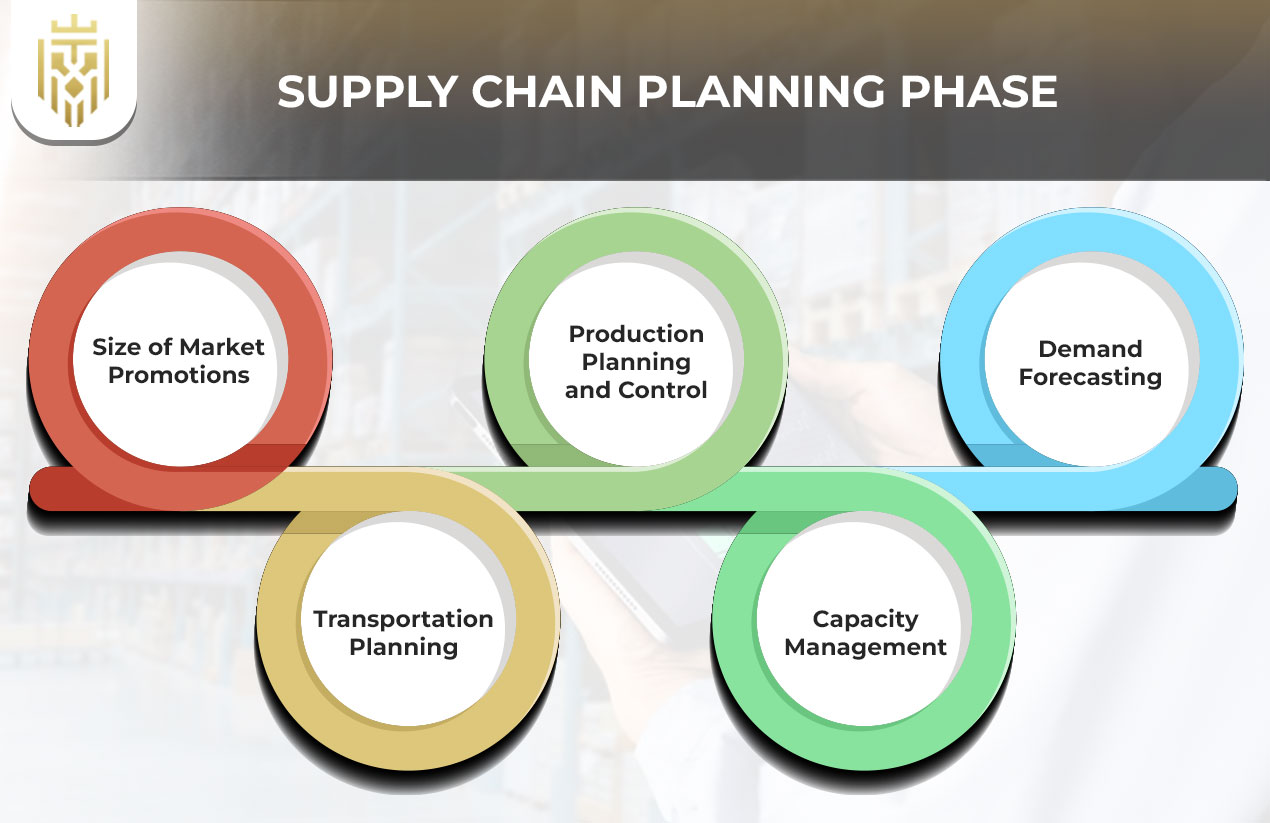

Supply Chain Planning Phase

This phase in the various decision phases in supply chain includes production, inventory and transportation steps that might take up to a year. Supply chain decisions aim to bring supply and demand into balance, making the workflow smoother and assuring successful supply chain activities.

Size of Market Promotions

Demand estimates and what is needed to produce can be strongly affected by how actively the market is promoted. Determining their size is important for keeping resources and stock in proportion. Thanks to information from this stage, the supply chain team can get ready better and react harmlessly, leading to a more successful outcome.

Production Planning and Control

At this point, the firm estimates how much demand there will be, decides on materials and organises when items will be produced. It helps balance how much work the supply chain performs and the capacity available. In making decisions in the supply chain, it helps save money and still get goods delivered on time.

Demand Forecasting

To meet customer’s needs, demand forecasting determines the required inventory and directs the sourcing and production processes. It is a significant choice, allowing the supply chain to react in real time. An important part of running a successful supply chain is making precise forecasts used in strategic design and planning.

Transportation Planning

Transportation planning optimises goods movement from origin to destination. You have to route your goods, pick the best carrier and organize the freight schedule. These decisions help cut costs, boost customer service and support the important workability of the supply chain.

Capacity Management

Capacity management involves matching the company’s capacity to meet the planned demand. The initial planning process for the supply chain helps avoid under use or putting too much strain on supply. This contribution improves the design strategy and supports the successful operation of the supply chain by optimising resources.

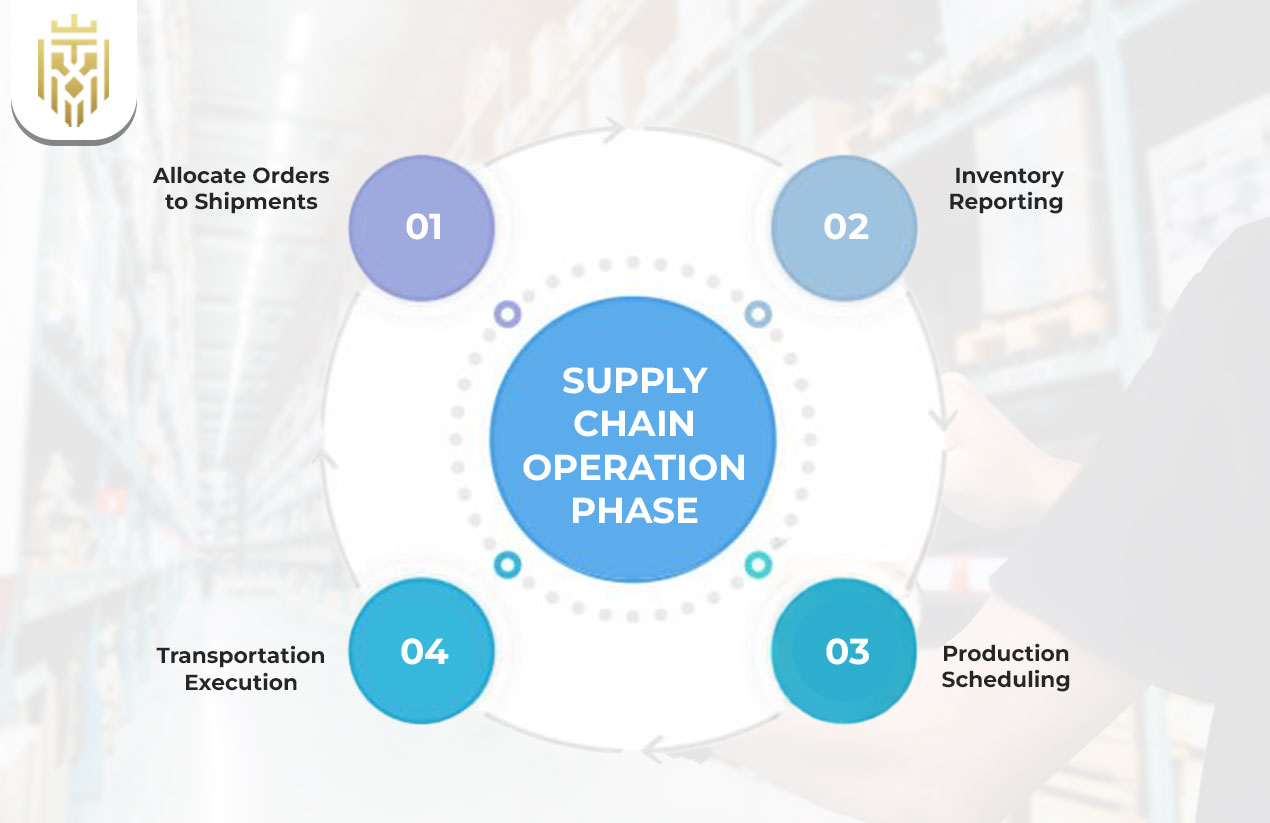

Supply Chain Operation Phase

The final phase of decisions in the supply chain involves making choices each day such as completing orders and overseeing inventory. Ensuring plans are followed every day helps customers, makes the company flexible and guarantees a successful supply chain with real-time data.

Allocate Orders to Shipments

The objective is to choose the best shipment method for each customer order. It is a decision about how to get products to customers on schedule and at the lowest cost. Through order allocation, a supply chain works smoothly because logistics are streamlined during various supply chain operation decisions.

Inventory Reporting

The purpose of inventory reporting is to keep track of stock and its movement. It allows for better decisions in ordering and organizing the warehouse. When flow information is improved, the design of the supply chain becomes more effective and so inventory reporting is fundamental in daily supply chain management.

Production Scheduling

The process of scheduling production simply means setting work tasks in an order that minimises time spent without work. Because of this choice, supply chain efficiency increases and practices involving just-in-time are possible. A well-integrated schedule coordinates activities with demand and is key to developing a winning supply chain design.

Transportation Execution

To achieve transportation execution, companies need to handle real-time deliveries. It results in quick arrivals, cost management and a seamless connection for information throughout the process. During this phase, daily activities are completed to uphold the system’s reliability and ensure the supply chain stays on top.

FAQs

1.What are the three Decision Phases in the Supply Chain?

The three decision phases in the supply chain are supply chain strategy phase, supply chain planning phase, and supply chain operations phase. These stages in supply chain management build out the long-term setup to ensure things remain steady during daily operations.

2.What are the components of supply chain strategy?

Capacity planning, network design, outsourcing decisions, and information systems infrastructure are the components of supply chain strategy. They plan out the best approach to design, help reduce expenses and strengthen the supply chain with smart decisions.

3.What are the components of Supply Chain Planning?

Size of market promotions, production planning and control, demand forecasting, transportation planning, and capacity management are the components of supply chain planning. Resources are organized and used efficiently at this stage by foreseeing demand with the help of support offerings and technology.

4. What are the Phases of Supply Chain Operation?

Allocate orders to shipments, inventory reporting, production scheduling, and transportation execution are the phases of supply chain operation. These choices keep daily routines in place, enhance actual performance and sustain the vital information needed for an effective supply chain.