What is Warehouse Management System?

A warehouse management system (WMS) is software designed to optimise warehouse operations, improve inventory control, and streamline order tracking. It improves stock management and proper logistic management and integrates with other systems to build a smart warehouse, which improves the efficiency of the entire warehouse as well as the supply chain.

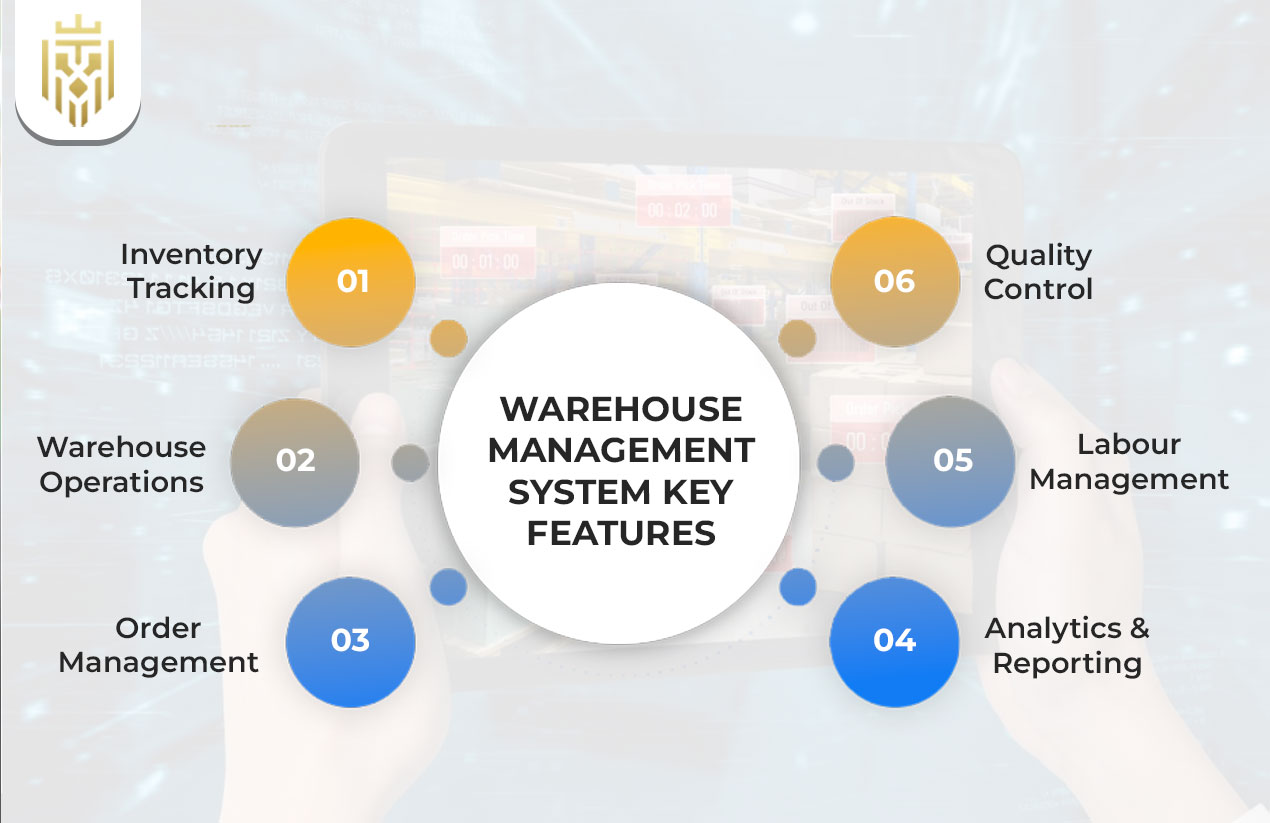

Key Features of a Warehouse Management System

The key features of a warehouse management system include efficient inventory control, accurate order tracking, optimised warehouse operations, and advanced warehouse automation. Such abilities enhance the logistics management system, real-time tracking, and overall efficiency of the warehouses, which assists companies in sustaining an efficient operation of all distribution centres.

Inventory Tracking

A warehouse management system provides precise inventory control and real-time tracking of stock. Businesses can be able to track the product locations, movement and quantities accurately, minimising the errors in managing the stock and helping in managing the logistics operations efficiently in all warehouse operations.

Warehouse Operations

Effective warehouse management software enhances overall warehouse operations by coordinating receiving, storage, picking, and shipping tasks. It guarantees the supply chain operations flow smoothly and allows managers to control the performance of distribution centres and the high efficiency of warehouses.

Order Management

A WMS for eCommerce helps streamline order tracking and fulfilment processes. Orders are given priority and efficiently handled minimising mistakes, optimising on the schedules of deliveries and enhancing efficiency in the warehouse in combination with updating the stock inventory to deal with precise stock management.

Analytics & Reporting

Advanced warehouse management system features include robust analytics and reporting tools. Managers will be able to trace the performance metrics, track the supply chain KPIs, and use the data to make decisions and optimise warehouse operations, improve inventory control, and increase the overall efficiency of the warehouse.

Labour Management

A modern warehouse management system optimises warehouse operations by efficiently allocating human resources. Positive labour management lowers operational bottlenecks, enhances productivity as well as smooth logistics management within the distribution centre hence, making the warehouse smarter and efficient.

Quality Control

A WMS allows a high level of quality control as it monitors the condition of products and compliance with their storage. Connection to inventory systems would guarantee the management of damaged stock or expired stock in time, keeping the warehouse at a high level of efficiency and enhancing the reliability of the supply chain.

Warehouse Management System Benefits

Implementing a warehouse management system delivers significant warehouse management system benefits, including improved stock management, enhanced order tracking, reduced errors, and increased warehouse efficiency. It enhances supply chain performance, inventory management, and logistics management, allowing it to make better decisions and be more reliable in its operations.

Improved Order Fulfilment

A warehouse management system improves order tracking and ensures accurate inventory control, enabling faster and more reliable order fulfilment. Increased exposure of the distribution centre leads to less errors and facilitates deliveries on time, which improves the efficiency of the warehouse and the overall supply chain.

Increased Productivity

The benefits of WMS include streamlined warehouse operations, reducing manual tasks, and improving employee efficiency. Stock management and logistics management through automation achieve guaranteed output, which increases the overall effectiveness of the warehouse and helps to fulfil the orders faster.

Cost Savings

Implementing warehouse management software can significantly reduce labour, storage, and operational costs. Through improved inventory management, stock management and distribution centre operations, organisations have been able to gain increased ROI and still attain high warehouse efficiency.

Enhanced Inventory Control

A warehouse management system ensures precise inventory control and minimises discrepancies. Stock management and order tracking, which are in real time, facilitate making decisions in the supply chain, minimising inaccuracies, avoiding excess stock, and increasing efficiency in the warehouse.

Better Customer Satisfaction

A WMS for eCommerce ensures accurate order tracking and faster order fulfilment, improving delivery reliability. Better customer satisfaction and reputation throughout the supply chain are the results of better distribution centre visibility and improved operations in the warehouses.

Reduced Waste

By integrating warehouse management software with inventory system data, businesses can minimise expired or excess stock. This minimises waste, streamlines warehouse activities, and enhances supply chain efficiency due to better stock management and warehouse efficiency.

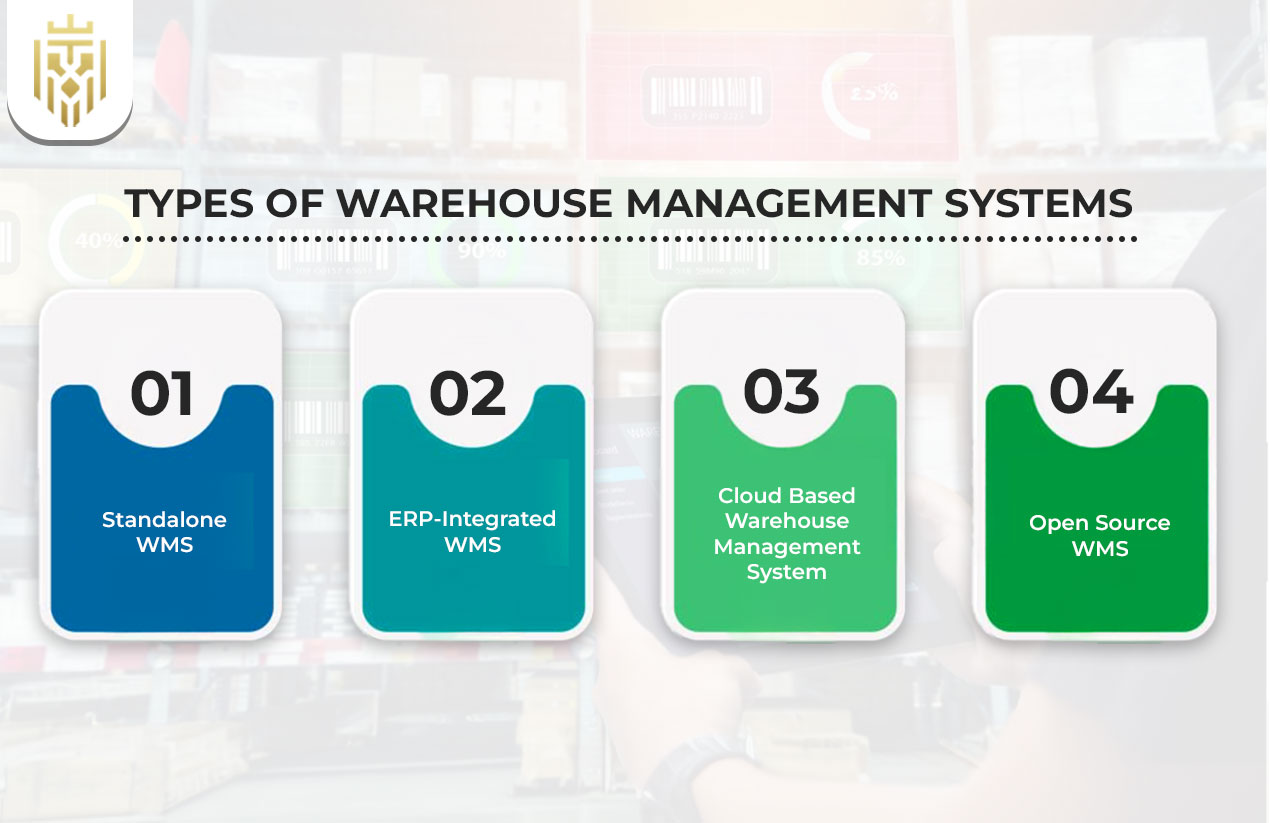

Types of Warehouse Management Systems

Understanding the types of warehouse management systems helps businesses choose suitable solutions. Options include standalone WMS, ERP-integrated WMS, cloud-based WMS, and open-source systems. Both types maximise the operations in the warehouse, improve inventory management and optimise the logistics management of the whole distribution centre.

Standalone WMS

A standalone WMS is self-sufficient and supports necessary inventory management and tracking of orders. It fits the solution requirements of businesses with simple warehouse operations management that does not need to be linked with larger ERP or cloud infrastructures.

ERP-Integrated WMS

A WMS with the integration of ERP has direct links with enterprise resource planning. Such integration guarantees smooth logistics, inventory, and stock management, through which it forms a cohesive workflow with distribution centres and provides more efficient work in the warehouse.

Cloud Based Warehouse Management System

A cloud-based warehouse management system allows real-time access to inventory systems and order tracking from multiple locations. Cloud integration enhances teamwork, decreases IT expenses, and offers scalable solutions to the current supply chain operations.

Open Source WMS

An open-source WMS offers customisable warehouse management software for businesses with specific operational needs. It helps in efficient operations of the warehouse, flexible control of inventory and integration with other supply chain systems with reduced costs of software licensing.

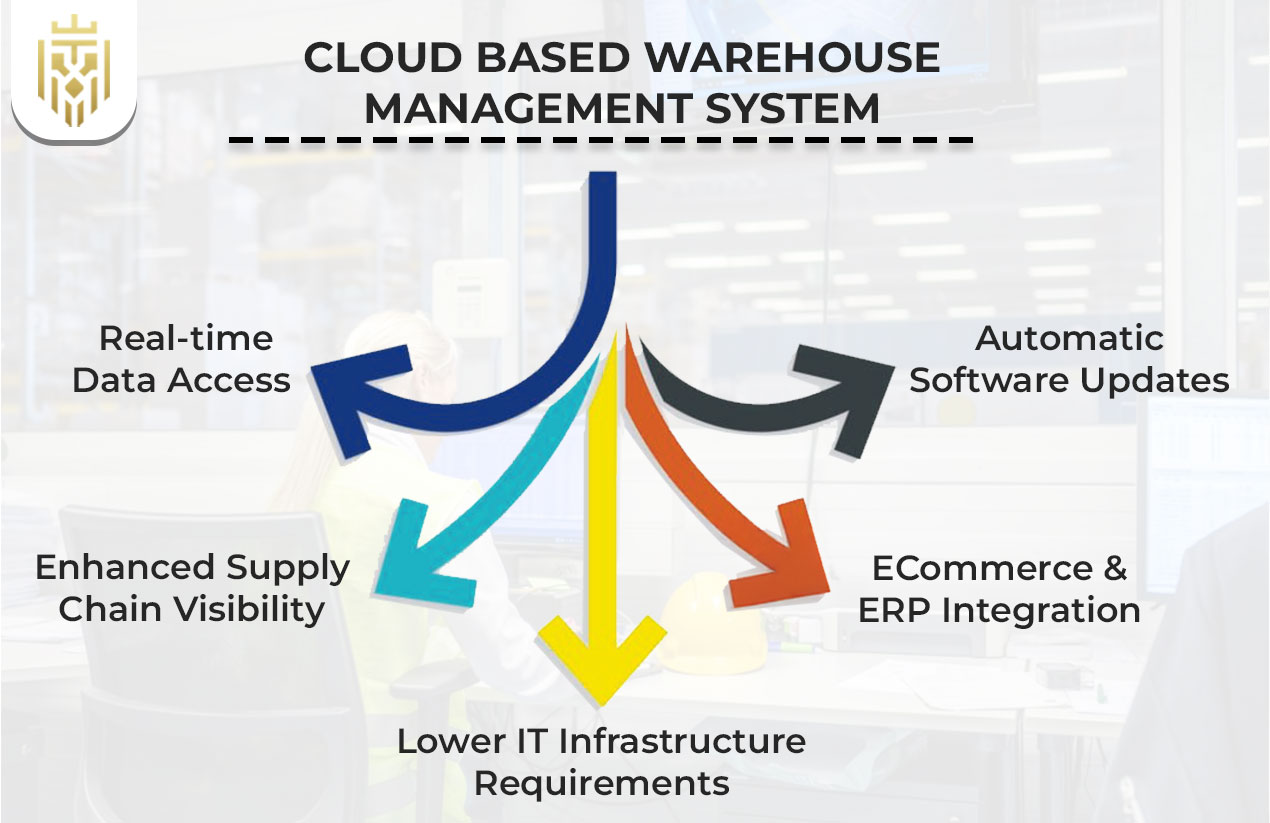

Cloud Based Warehouse Management System

A cloud-based warehouse management system provides real-time data access, inventory control, and enhanced collaboration across multiple locations. It supports order tracking, warehouse automation, and integration with WMS for eCommerce, improving overall warehouse efficiency and simplifying logistics management within modern supply chains.

Real-time Data Access

A cloud based WMS provides real-time tracking of inventory across multiple facilities. This facilitates centralised monitoring and enhanced warehouse operations, as well as enables visibility of the supply chain, which enhances management of stocks and overall warehouse performance.

Enhanced Supply Chain Visibility

Cloud solutions enhance teamwork and third-party collaboration. A cloud based WMS enhances logistics management, ensures transparent inventory control, and strengthens warehouse operations across all distribution centres within the supply chain.

Lower IT Infrastructure Requirements

Using cloud based WMS software reduces on-premise IT requirements. Companies can ensure their warehouse operations are efficient, manage their stocks efficiently and enhance the performance of their supply chain without investing in a physical infrastructure or sophisticated warehouse automation.

eCommerce & ERP Integration

A cloud based WMS integrates seamlessly with ERP platforms and WMS for eCommerce, enabling real-time inventory control, faster order tracking, and more efficient warehouse operations across distribution centres.

Automatic Software Updates

Cloud platforms provide automatic updates to warehouse management software, ensuring the latest features in inventory control, warehouse automation, and logistics management are available without manual intervention, improving warehouse efficiency and overall supply chain performance.

Warehouse Automation and Efficiency

Implementing an automated warehouse system improves warehouse operations, reduces manual errors, and enhances warehouse efficiency. Such characteristics as real-time monitoring, intelligent warehouse systems, and integrating inventory systems streamline logistics management and optimise the work processes throughout the distribution centres.

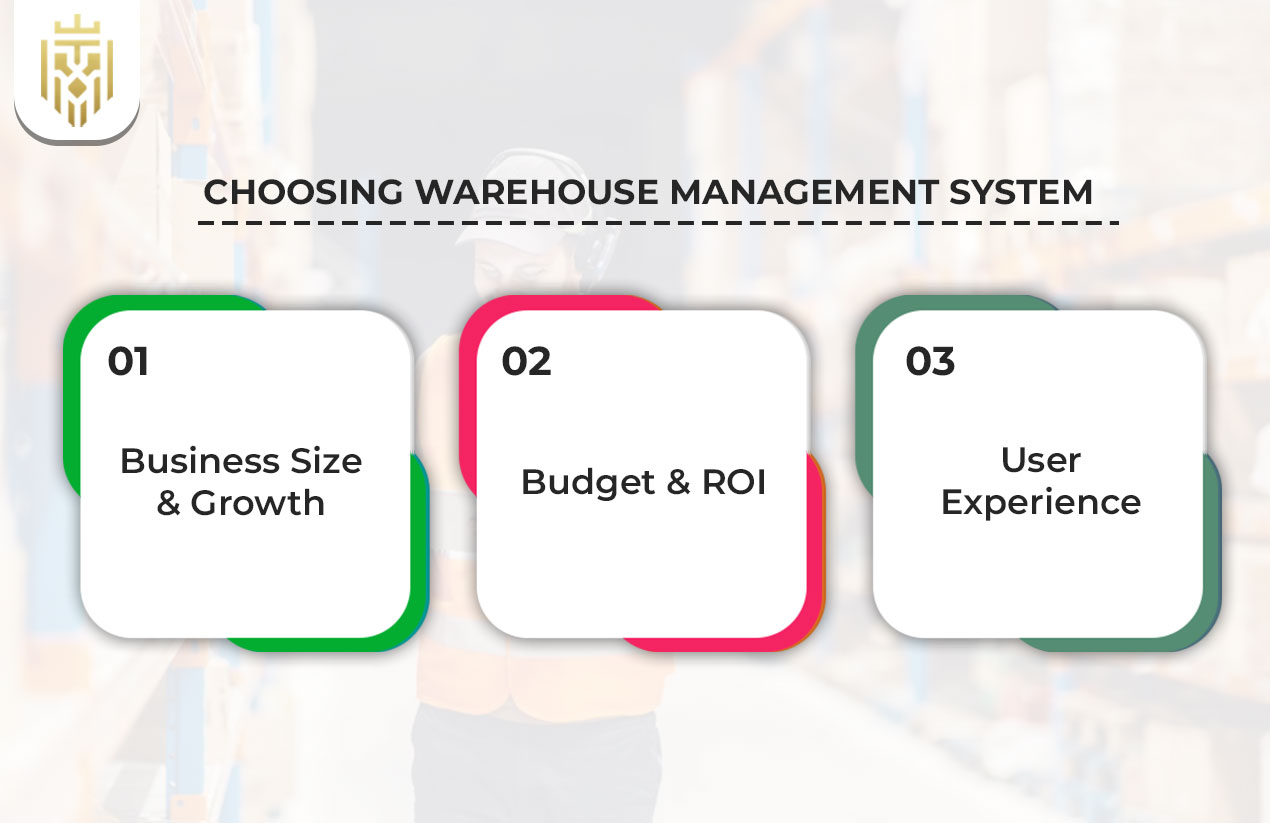

Choosing Warehouse Management System

Selecting the right warehouse management system requires evaluating business size, growth, budget, and integration needs. An appropriately selected warehouse software enhances the inventory control, warehouse operations, and supply chain efficiency and provides scalability and flexibility to changing logistics management needs and future warehouse automation objectives.

Business Size & Growth

Selecting a warehouse management system depends on business scale and growth. Small companies could use standalone warehouse software, while larger enterprises benefit from cloud based WMS or ERP-integrated WMS, enhancing warehouse operations, inventory control, and logistics management.

Budget & ROI

WMS selection is affected by budget factors. Investing in cloud based WMS software or automated warehouse system solutions can increase upfront costs but deliver long-term ROI through improved warehouse efficiency, reduced labour and optimised stock management.

User Experience

A WMS with intuitive warehouse management software ensures employees can easily manage inventory control, order tracking, and warehouse operations. The focus on the user experience will enhance the adoption of the WMS implementation, accuracy and the efficiency of the distribution centre in general.

FAQs

1. How does a warehouse management system improve labour productivity?

A warehouse management system enhances labour productivity through warehouse automation, task allocation, real-time tracking, and workflow adjustment and efficiency, minimal error in manual work, and management of overall warehouse efficiency and logistics.

2. How is WMS different from inventory management software?

In contrast to simple inventory management solutions, a WMS is in charge of all the activities of the warehouse (order tracking, warehouse automation and labour management) providing more control and visibility to the whole supply chain.

3. Is a cloud based warehouse management system secure?

Yes, cloud based warehouse management system will be secure with encrypted data, access control, and frequent updates, which will guarantee safe real-time tracking, trustworthy inventory control, and secrecy of sensitive information about the operations of the warehouse.

4. How does WMS support eCommerce businesses?

eCommerce WMS enhances the online businesses with better order tracking, inventory, and warehouse automation to provide faster deliveries, proper stock changes and the supply chain integration to support seamless warehouse performance.