What is Predictive Maintenance?

Predictive maintenance is a proactive strategy that utilizes real-time data and analytics to forecast when equipment is likely to fail or require servicing. It predicts failure and schedules maintenance before issues occur. It helps in optimizing performance, reducing downtime, and extends the lifespan of equipment.

In the context of warehouses, predictive maintenance plays a crucial role in ensuring that equipment, such as forklifts, conveyor belts, automated storage systems, warehouses can transition from reactive maintenance to proactive systems, warehouses can evolve from reactive maintenance to proactive maintenance, resulting to cost savings, improved productivity, and optimized warehouse operations.

Predictive Maintenance in Warehouses

Warehouses depend massively on equipment and automation systems to keep supply chain operations run smoothly and efficiently. Executing predictive maintenance in warehousing assures that these assets perform at their peak while reducing operational disturbances.

Improving Asset Lifespan

Every part of warehouse equipment has a specific operational life, but the expiry date depends on its usage and maintenance. Predictive maintenance uses sensors and loT tech to monitor the condition of equipment regularly. Early detection of potential issues like overheating motors, unusual vibrations, or declining performance assures timely intervention. This not only avoids sudden breakdowns but also stretches the overall lifespan of assets, maximizing return on investment.

Enhances Productivity

Unexpected downtime is one of the biggest hurdles to warehouse productivity. Predictive maintenance technology use assures that equipment failures are foreseen and can be addressed before they affect workflow. For instance, predictive analytics in logistics can alert managers about a conveyor motor nearing failure, that allows them to schedule maintenance without pausing production. By reducing downtime and keeping equipment fully operational, warehouses experience improved throughput and higher productivity levels.

Reduces Costs

Traditional maintenance approaches often results in unnecessary repairs or delayed interventions that will result in costly breakdowns. Predictive maintenance minimizes costs by addressing issues only when needed. IoT predictive maintenance systems spot anomalies at an early stage, which helps avoid major repairs or equipment replacements. Furthermore, proactive maintenance reduces labor costs, spare part expenses, and operational losses from unscheduled downtime.

Minimizing Downtime

Downtime in warehouses not only interrupts operations but also disrupts the supply chain. Predictive maintenance helps reduce downtime in warehousing by enabling real-time monitoring and predictive modeling. Maintenance teams can plan interventions during low-demand periods, assuring operations remain unaffected. This leads to the supply chain becoming more flexible, reliable, and efficient.

Supports Smart Warehousing

Predictive maintenance is the pillar of smart warehousing strategies. With automation, robotics, and AI becoming integral to modern warehouses, predictive analytics assures these systems incorporate with warehouse management systems (WMS) to provide effortless visibility, anticipating insights, and optimization across operation. This leads to data-driven maintenance strategies that support smarter, safer, and more efficient warehouse operations.

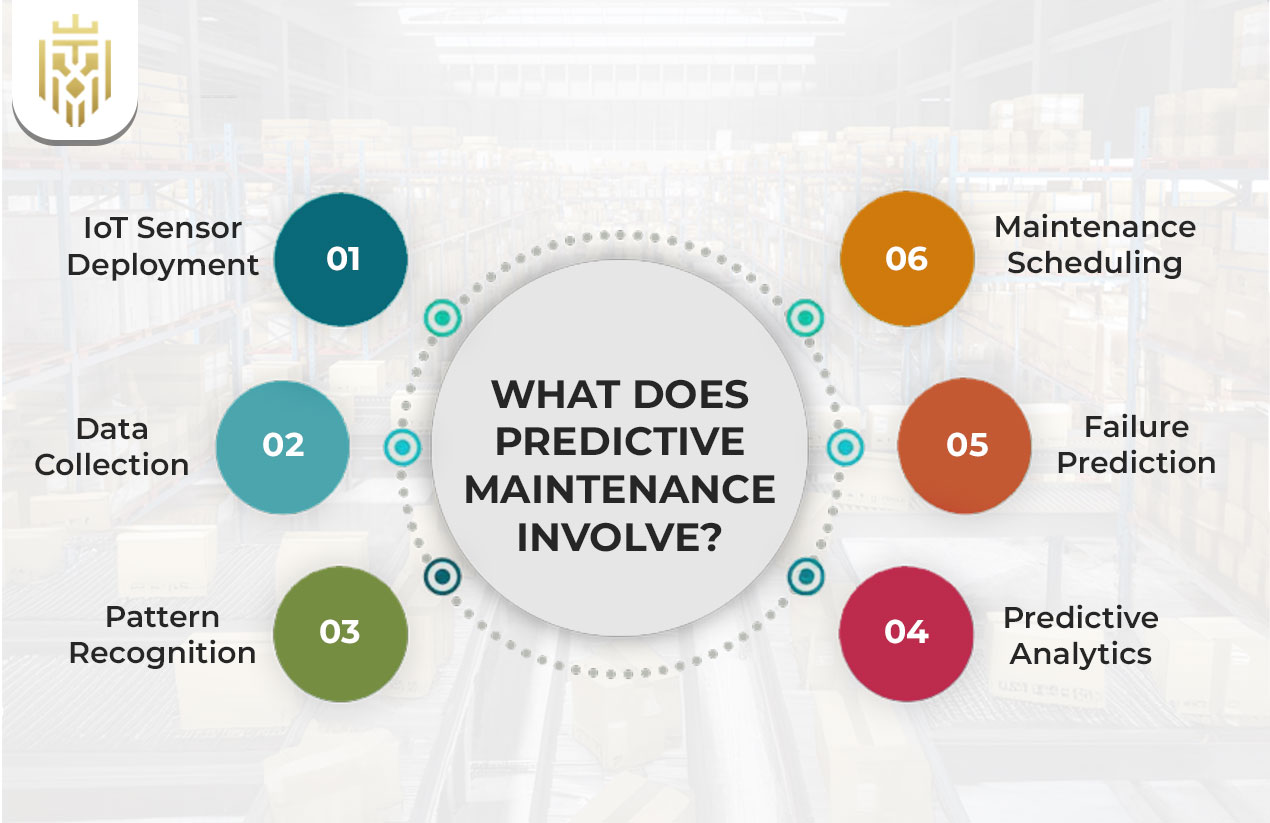

What Does Predictive Maintenance Involve?

Predictive maintenance involves several key steps that leverage IoT, sensors, and analytics to optimize equipment performance.

IoT Sensor Deployment

Sensors are the backbone of predictive maintenance. They are arranged on warehouse equipment to measure crucial parameters like temperature, vibration, energy consumption, and pressure. By frequently monitoring these variables, sensors support real-time insights into the health of assets.

Data Collection

The data collected from IoT sensors is transferred to centralized systems for analysis. This data includes performance metrics, historical usage trends, and environmental conditions. Having access to large datasets grants warehouses to understand the different behaviors of equipment in various circumstances.

Pattern Recognition

Machine learning maintenance models examine historical and real-time data to diagnose patterns. For example, recurring spikes in vibration levels may indicate misalignment in conveyor belts. Identifying these patterns helps in early detection of issues and guides maintenance teams to take preventive measures.

Predictive Analytics

Predictive analytics is at the core of predictive maintenance in warehousing. Using advanced algorithms and data modeling, predictive analytics forecasts potential failures before they happen. These proactive maintenance schedules ensure maximum asset performance.

Failure Prediction

Failure prediction uses machine learning models to assess the probability of equipment breakdowns. By considering risk scores for different assets, warehouses can prioritize maintenance activities on high-risk equipment. This assures that resources are assigned effectively, preventing costly disturbances.

Maintenance Scheduling

Maintenance scheduling is one of the biggest advantages of predictive maintenance. Instead of performing maintenance at fixed intervals, teams can schedule. Instead of performing maintenance at fixed intervals, teams can schedule interventions based on actual equipment condition and predictive insights. This reduces unnecessary servicing and ensures timely interventions, boosting efficiency and reliability.

Role of AI & IoT in Predictive Maintenance

AI (Artificial Intelligence) and the Internet of Things (IoT) are central to predictive maintenance implementation in warehouses.

Remote Monitoring

IoT sensors connected to cloud-based platforms, allowing remote monitoring of warehouse equipment. Maintenance teams can track asset performance in real-time, regardless of location. This capability assures issues are identified and resolved promptly, improving equipment reliability.

WMS Integration

Integration of predictive maintenance systems with WMS (Warehouse Management Systems) ensures effortless data sharing. For example, predictive analytics can signal managers about a potential forklift malfunction, and the WMS can automatically adjust operations or reroute tasks to other assets. This integration drives smarter decision-making and improves warehouse optimization.

Proactive Maintenance

AI-powered predictive analytics allows proactive maintenance, where potential issues are determined before they expand. Proactive maintenance not only prevents downtime but also improves workplace safety by ensuring that critical assets such as safety equipment remain fully functional.

Applications of IoT Predictive Maintenance in Warehouses

Predictive maintenance is flexible and can be applied to different warehouse systems and equipment.

Conveyor Systems

Conveyor systems are the backbone of material handling in warehouses. Predictive maintenance monitors vibrations, motor temperatures, and energy consumption to detect early signs of wear. Timely interventions prevent conveyor stoppages, ensuring the smooth flow of goods.

Forklifts & AGVs

Forklifts and Automated Guided Vehicles (AGVs) are critical for material movement. Predictive analytics tracks battery health, tire wear, and motor performance. This prevents sudden breakdowns and ensures safe and reliable operations.

Safety Equipment

Fire suppression systems, emergency alarms, and sprinklers are vital for warehouse safety. IoT-based predictive maintenance ensures that safety equipment is regularly monitored, tested, and always ready for use. This minimizes risks and improves workplace safety.

AS/RS (Automated Storage and Retrieval Systems)

AS/RS systems depend on robotics and automation for inventory management. Predictive modeling tracks mechanical parts, sensors, and electrical systems, ensuring seamless performance. Preventive measures keep AS/RS systems reliable and efficient.

HVAC Systems

Warehouse HVAC systems regulate temperature and ventilation, crucial for storing sensitive products. Predictive maintenance monitors energy use, air flow, and filter conditions. By identifying inefficiencies early, predictive analytics reduces energy costs and enhances asset performance.

FAQs

1) Can predictive maintenance be applied to non-automated warehouses?

Yes, predictive maintenance can benefit both automated and non-automated warehouses. Even in manual warehouses, equipment like forklifts, HVAC systems, and safety devices can be monitored using IoT-based predictive maintenance.

2) What role does machine learning play in predictive maintenance?

Machine learning maintenance models analyze large datasets to detect patterns, forecast failures, and improve predictive accuracy. This helps create more reliable and data-driven maintenance strategies.

3) Is predictive maintenance suitable for small-scale warehouses?

Absolutely. Predictive maintenance is scalable and can be implemented in small-scale warehouses to optimize asset performance, reduce downtime, and save costs.

4) How does predictive maintenance improve workplace safety?

By ensuring equipment such as forklifts, fire alarms, and ventilation systems are continuously monitored, predictive maintenance prevents hazardous situations. This enhances workplace safety for warehouse employees.

5) What industries benefit most from predictive maintenance in warehousing?

Industries with high reliance on warehouses and logistics—such as e-commerce, retail, pharmaceuticals, and manufacturing gain significant advantages from predictive maintenance. It ensures efficiency, reliability, and uninterrupted supply chain operations.