What is Nearshoring?

Nearshoring is a business model in which firms relocate manufacturing or sourcing to their core market. The nearshore meaning signifies moving functions to neighbouring nations, enhancing the speed of delivery, economical operation, and cooperation, and minimising risks associated with long-distance international trade reliance.

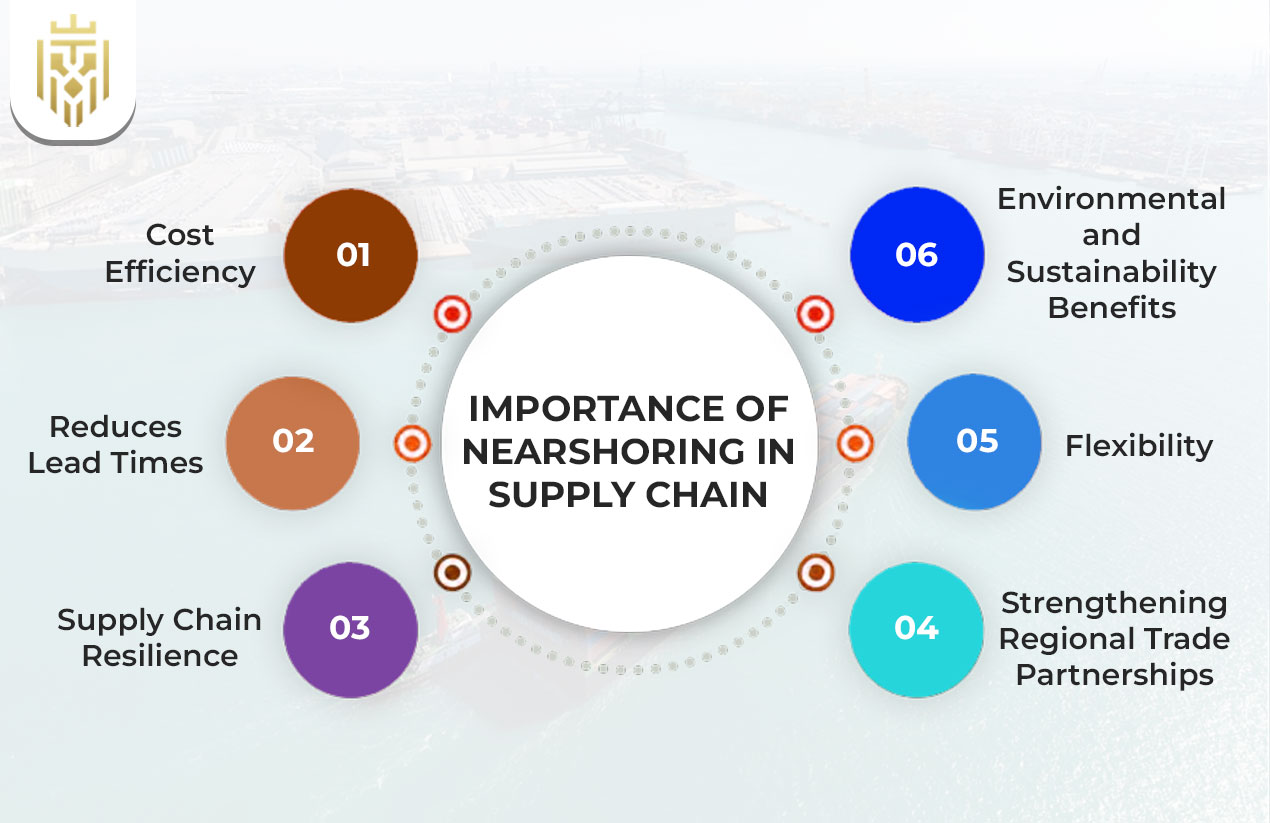

Importance of Nearshoring in Supply Chain

Nearshoring is important to the supply chain because it enhances agility, minimises risk exposure, and strengthens partners. It promotes the regionalization of supply chains and facilitates regional hubs, as well as greater coordination among trade partners and suppliers, making its operations more stable and efficient than in distant sourcing models.

Cost Efficiency

Nearshoring can also minimise transportation and operation costs. Local suppliers ensure that companies become cost-effective, have a better command of costs, and deliver their products more quickly, so they can make smarter decisions regarding sourcing strategies that promote an increase in total profitability and competitiveness in the global market.

Reduces Lead Times

Placing production close to end markets drastically reduces the lead times. Using a nearshore supply chain strategy, the supply chain will be optimised faster, be more responsive and have fewer delays, which will enhance competitive advantage in sectors where speed and flexibility are vital.

Supply Chain Resilience

Resilience in the nearshore supply chain is enabled by reducing transport and geopolitical impacts that create disruptions during long supply routes. Tighter relations between the supplier will enable agile changes and allow business to adapt fast, which guarantees continuity, and provide supply chain risk mitigation strategies towards sustainable operations.

Strengthening Regional Trade Partnerships

The nearshoring supply chain management enhances economic engagements through the strengthening of trade partners’ relationships. Regional production strengthens the level of cooperation, opens possibilities of development and strengthens regional economies. This interdependence creates strategic benefits in the long term and assists in stabilising trade flows, which are beneficial to the companies and the local industries.

Flexibility

Operational flexibility is one of the best benefits of nearshoring. The diversification of the supplier network also enables the company to react more to the fluctuations in demand trends, increase the level of sourcing agility, and be more responsive to market fluctuations, which improves the overall supply chain performance and strategic positioning.

Environmental and Sustainability Benefits

Nearshoring helps in supporting greener operations by reducing the shipping distance. This reduces emissions and is in line with sustainability objectives. Other advantages of nearshoring supply chain will be the ability to reduce carbon footprints and improved compliance with eco-friendly policies, which will form a more responsible and efficient sourcing model.

Nearshoring vs Offshoring

Contrary to offshoring, where the operations are transferred to distant countries, nearshoring retains sourcing to major markets. The approach minimises transit, enhances coordination, and reduces disruption. It also allows us to control the quality better and enhance the regional hubs, which makes the supply chain more efficient and adaptable.

Nearshoring vs Friendshoring

While friend-shoring is concerned with the placement of supply to trusted partners, nearshoring is concerned with geographical location. This difference enhances responsiveness and reduces the transportation expenses. A combination of the two can ensure risk management approaches, which establish more resilient networks that fail to balance geopolitical stability and logistical efficiency.

Strategic Benefits of Nearshoring in Supply Chains

Nearshoring supply chain has strategic advantages such as speed of delivery, improved communication, and visibility. Combining smart sourcing strategy and local networks, the companies can have more powerful control over their actions and make their supply chains more agile, transparent, and cost-effective.

Improved Collaboration and Communication

Closeness improves co-operation and coordination. The direct benefit of nearshore logistics is more obvious as teams can also communicate in real time. This results in quicker decision making, easier running of operations and closer harmonisation of stakeholders in various sections of the supply chain.

Risk Management and Continuity

Nearshoring enhances the effectiveness of risk management because supply lines are less likely to break down due to the presence of shorter lines. Regional sourcing guarantees continuity of the business, helps businesses to mitigate supply chain risks and also avails business with reliable alternatives in case of global uncertainties.

Quality Control and Operational Transparency

Nearshoring enhances supervision as the closer the supplier to the company the better the monitoring. The business can have a substantial amount of transparency in its operations, improved visibility of suppliers and more quality control which makes sure that the products are of good quality and production does not require costly mistakes or hold-ups.

Regional Hubs for Strategic Advantage

Establishing regional centres allows to streamline logistic processes and achieve quicker delivery. These hubs are essential intermediaries of suppliers and markets, which facilitate optimization of the supply chains and enable nearshoring to be a strategic facilitator of flexible and scalable distribution networks.

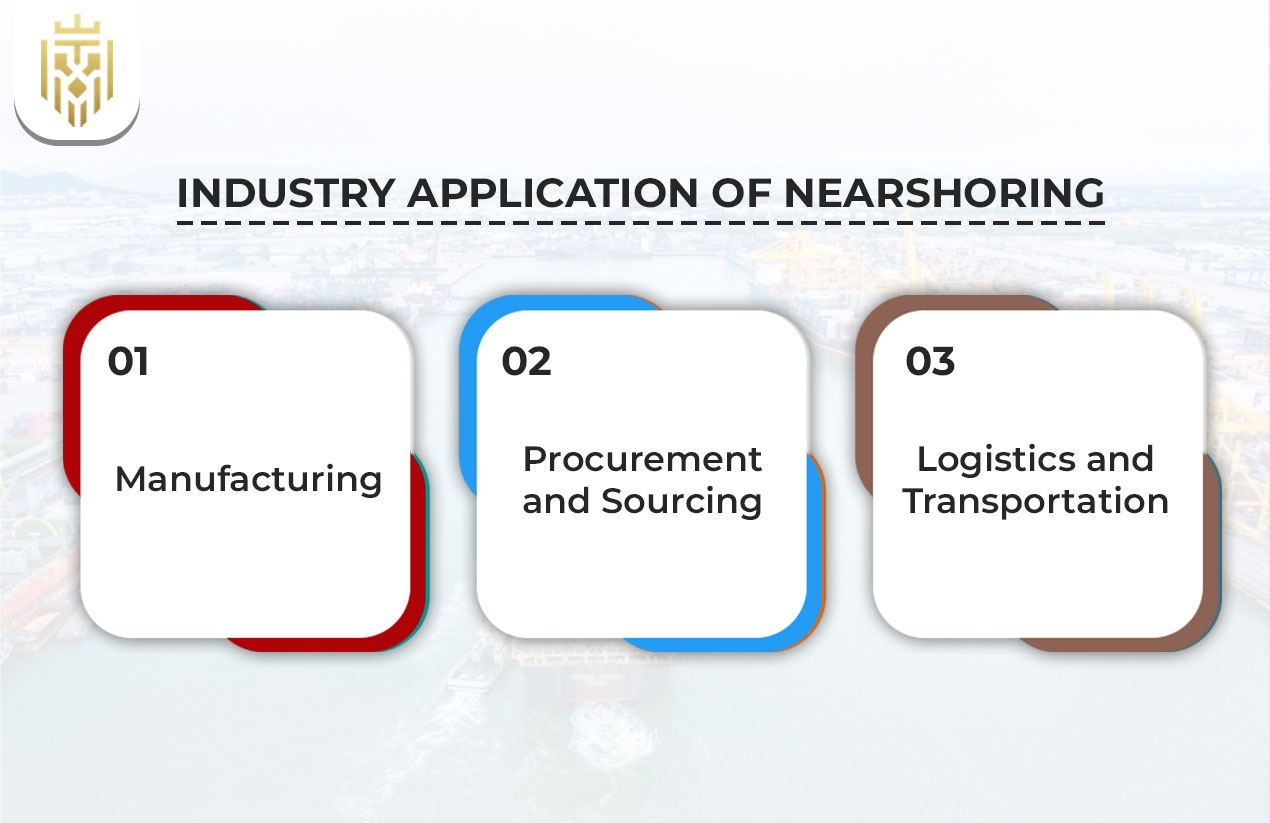

Industry Application of Nearshoring

Nearshoring supply chain is becoming more popular in such industries as manufacturing, retail, and technology. The use of local suppliers and regional hubs would help enhance responsiveness, shorten lead times, and increase localization of the supply chain enabling firms to maximise their operations as well as boost resilience and cost-efficiency.

Manufacturing

Manufacturers use nearshoring to shorten the lead times, manage quality, and cut down the expense. Based on proximity, operations become more efficient and more flexible, and competitive positioning in the global trade becomes stronger due to increased integration with suppliers and quicker responsiveness to the market.

Procurement and Sourcing

Nearshore strategy in supply chain changes procurement by motivating cooperation between suppliers. In closer sourcing, the communication becomes effective, and the contracts are fulfilled faster, leading to sustainable goals of procurement, which achieves increased flexibility to the changing market conditions and demand by the customers.

Logistics and Transportation

The benefits of nearshore logistics are that it has fewer transit paths, less cost, and improved predictability of delivery. This makes supply chains stronger, efficient in transportation and aids in localising supply chains, making operations responsive and environmentally friendly.

Challenges in Implementing Nearshoring

The challenges that can be encountered through implementing nearshoring supply chain management include infrastructural barriers, regulatory burden, and lack of skilled workers. One of the ways to handle these issues will be cautious sourcing policy, logistics investment, and supplier network design that will allow making the transitions effective and maintainability of supply chain functions.

Infrastructure Limitations

Infrastructure restricting may prevent the adoption of nearshoring. Lack of adequate transport and port facilities can slow down their operations and lower their efficiency. To handle these concerns, it is necessary to invest in the logistics networks and better planning and improved transport systems to maximise the benefits of nearshoring.

Regulatory Complexity

Supply chain nearshoring may entail the process of manoeuvring through complicated trade laws, customs, and compliance specifications. Balancing such processes at the border level guarantees the fluent functioning and preservation of risks, as well as competitive efficiency in the regional sourcing policies.

Labor Market Constraints

Nearshoring can be affected by local labour deficiencies or skills deficiency. Developing a close relationship with regional hubs and investing in human resources will guarantee sustainable growth, enhancing the stability of production and operations of operations in the long term.

Initial Transition Costs

The conversion to nearshoring is usually accompanied by initial investments in plants, technology, and labour force. These costs may be initially high but they provide cost efficiency and resilience of operations in the long run, which makes the strategy a brilliant decision to grow in the future.

FAQs

1. How does nearshoring impact local economies?

Nearshoring builds local suppliers, job creation and regional hubs. It enhances investment, creates skilled labour markets, and facilitates the localisation of the supply chain to achieve sustainable economic growth.

2. What technologies support nearshoring strategies?

The nearshore supply chain strategy is improved by digital supply networks, automation, AI, and real-time visibility tools to allow businesses to be agile in sourcing, effective in production, and responsive to the rapidly changing market.

3. Is nearshoring suitable for small and medium enterprises (SMEs)?

Yes, nearshoring advantages SMEs in terms of low shipping expenses, speedier delivery, better supply chain and fewer risks and thus makes operations more dynamic and cost-effective.

4. How does nearshoring contribute to ESG goals?

Nearshoring helps mitigate risks in the supply chains and minimise emissions by travelling by shorter routes. It brings into existence responsible sourcing, sustainable operations, and alignment of global trade with ESG standards.