Understanding Material Flow in Supply Chain

Material flow is a way in which goods are transferred between suppliers and customers in any operations. Planning the processes makes the process flow and coordination between procurement, production, distribution and returns smooth. Increased visibility and automation of real-time material flow are used in modern systems to reduce delays and support efficient performance by the supply chain.

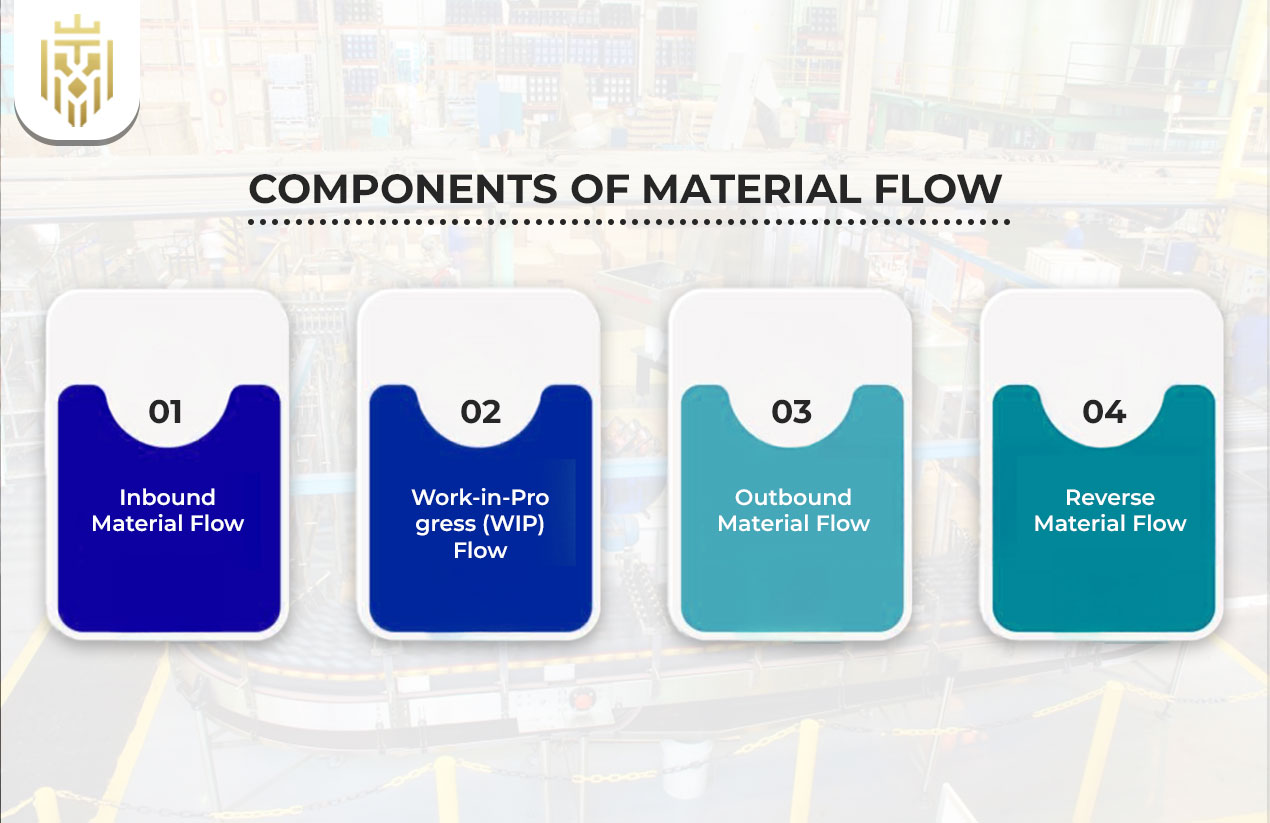

Components of Material Flow

Movement, storage, handling equipment, people, and information systems are the main elements of the material flow that harmonise the supply chain process. Good coordination of these components would guarantee timely transfer of products, optimisation of warehouse space, better productivity and lean logistics operations of the warehouse by eliminating bottlenecks and enhancing efficiency in procurement, warehousing and distribution processes.

Inbound Material Flow

Inbound material flow involves the provision of raw materials, the receipt of raw materials, and the stocking of raw materials used in production. Timely availability is made possible by efficient control of inventory and coordination with the suppliers. Companies are using the material flow analysis in order to streamline and reduce waiting time and maintain production schedules without bottlenecks in the procurement stages.

Work-in-Progress (WIP) Flow

WIP flow is used to monitor movement of semi-finished products between workstations. Effective production planning ensures that one does not produce excessively or stockpile. Use of material flow in manufacturing strategies and lean systems, as well as planned workstation scheduling, will provide efficient transition, reduced waste, and constant output at every manufacturing process step.

Outbound Material Flow

Outbound flow makes the distribution of finished goods to distributors and customers effective. Shipping schedules and storage capacity are in sync with appropriate logistics management. Combining flow optimisation and route planning technologies reduces delivery interruptions and stockpiles, as well as providing a continuous supply chain of operations through the distribution channels.

Reverse Material Flow

Reverse flow deals with returns, recycling, repair and recovery of waste. Focusing on the sustainable material flow issues contributes to reuse and reduces footprint. Quality checks and refurbishing are also made easy by real-time tracking and organised protocols in returning, which facilitate customer satisfaction and minimise landfill waste and logistical overhead.

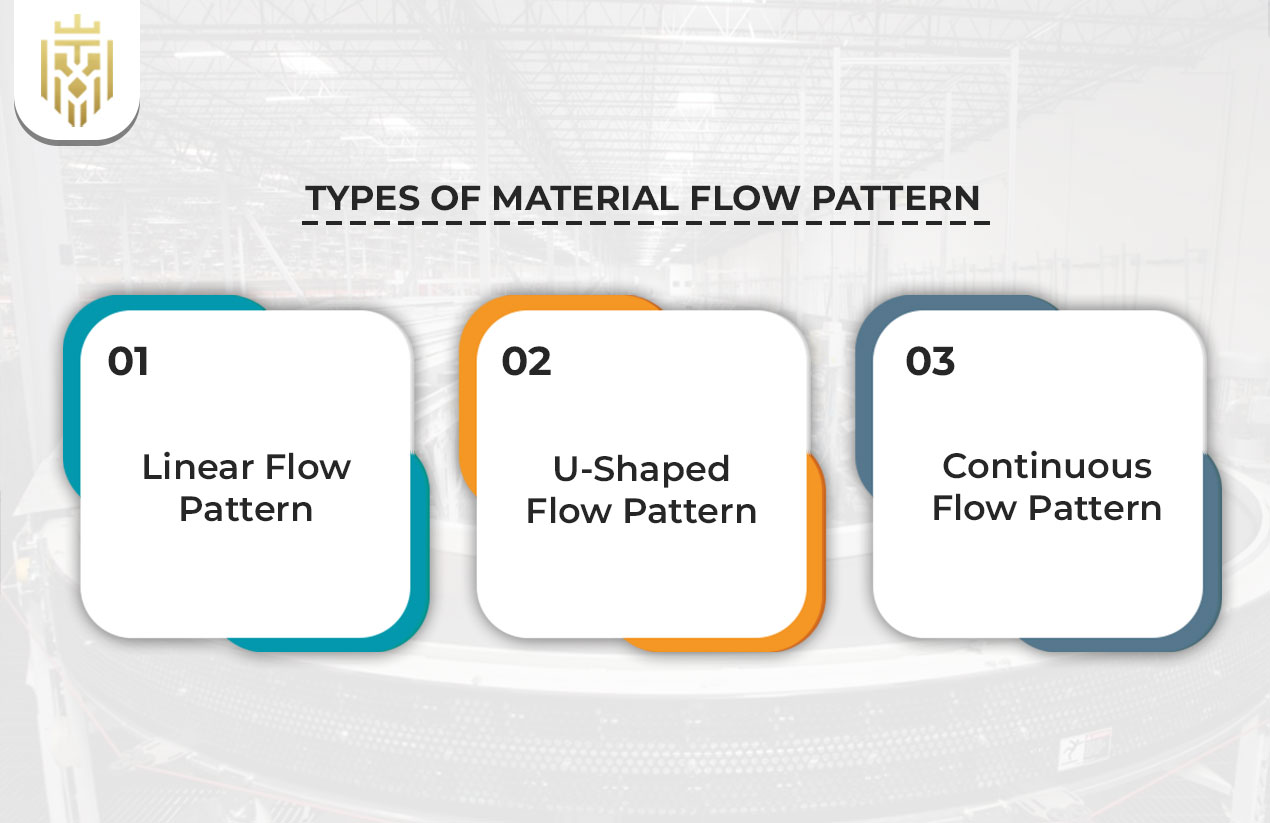

Types of Material Flow Pattern

There are different patterns of material flow based on the layout of the facility and the objectives of the operations, such as straight-line, U-shaped, circular and hybrid flows. The appropriate flow pattern can be chosen to maximise the travel distance, increase the space use, and improve the process of orders. Flexible hybrid layouts are now being used in modern logistics facilities to allow automation and fluctuating SKU movement rates.

Linear Flow Pattern

A linear material flow pattern involves the movement of goods in a direct order beginning with raw materials and ending with finished products. This model is appropriate in simple operations. It minimises downtime when used in conjunction with accurate resource planning but could be inefficient in situations where product differentiation or individualisation needs to rise during supply operations.

U-Shaped Flow Pattern

In a U-shaped pattern, input and output points are spaced out near each other. It is best used in warehouse management to improve the efficiency of the operators and expedite the movement of the operators across workstations. This trend encourages the enhancement of the efficiency of material flow by reducing the travel distance and enhancing the productivity and ensuring that the labour is not fatigued in a small manufacturing area.

Continuous Flow Pattern

Continuous flow refers to constant movement of materials, particularly in automated settings. Goods move readily through each of the stages with a strong material flow network design. The strategy is popular when dealing with operations of high volume, where it is possible to produce uniform output volume, a low buffer stock, and predictable flow of materials along the production pipeline.

Material Flow Analysis

Material flow analysis involves an assessment of material flow into, through and out of a system. It also determines the areas of inefficiency and waste and is also used to direct the areas of resource planning. Companies use real-time tracking and systematic data analysis to optimise decision-making of material flow patterns, minimise delays, and help in the unremitting supply chain enhancement in line with the operational requirements.

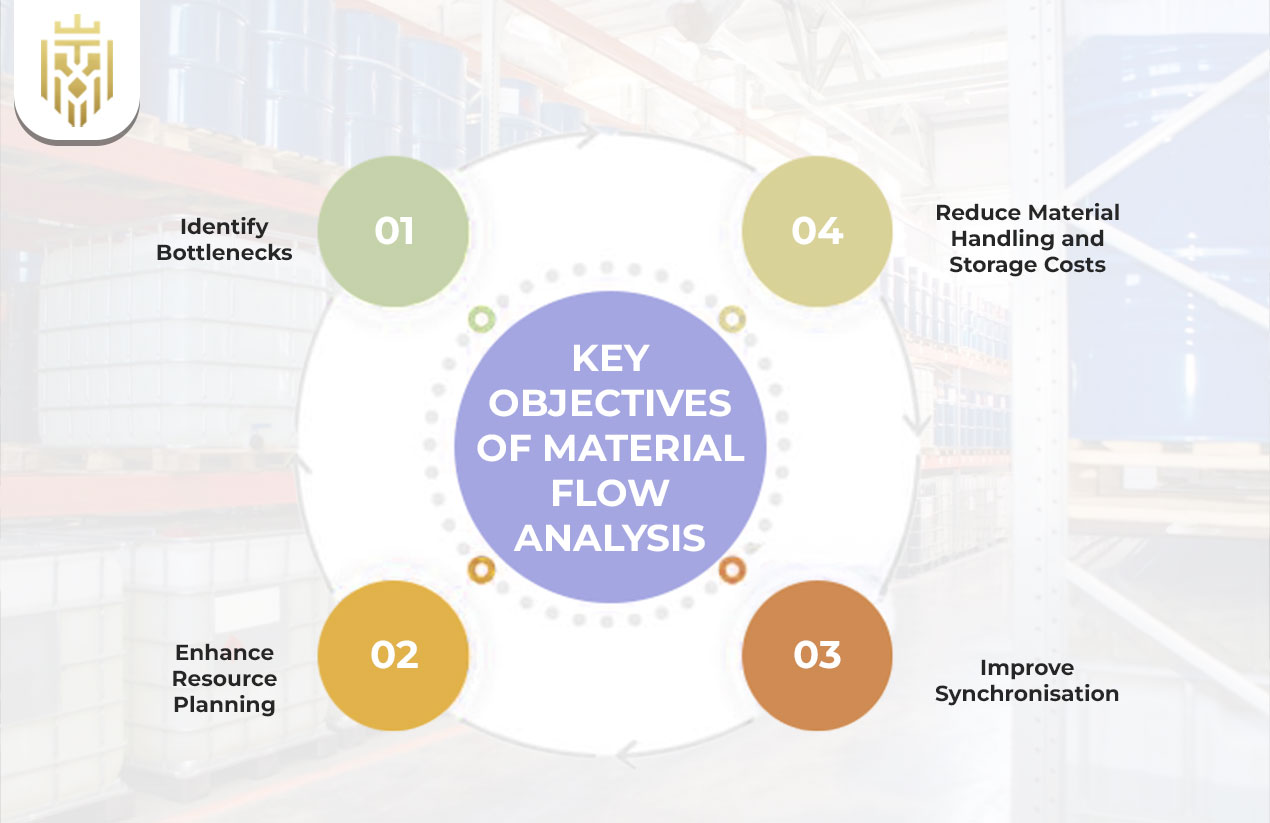

Key Objectives of Material Flow Analysis

Material flow analysis determines wastes, delays and inefficiencies in the networks. Some of the key objectives involve enhanced coordination, better demand forecasting and smooth flow of goods. It also guarantees a material flow of the supply chain in supply chain visibility, which enables a business to maintain low costs, an equal workload and constant availability of items.

Identify Bottlenecks

This step identifies the points of stalling and congestion. Through accurate material flow, organisations identify the slowness of workstations, overused storage space, and ineffective transportation routes and make appropriate improvements and speed up processes through facilities.

Enhance Resource Planning

Improving resource planning will make sure that materials, equipment and labour meet the production requirements. Forecasting based on the data assists companies in planning work, making the most of the raw materials stored, and sustaining the output with the help of the strategic decisions about the material flow.

Improve Synchronisation

Synchronisation enhances rhythm in procurement, production and distribution. System integration improves the collaboration, warehouse management is simplified and idle machinery is avoided to ensure continuous and productive operations based on real-time supply requirements.

Reduce Material Handling and Storage Costs

Handling cost reduction reduces transportation steps, stacking efficiency, and simplifies storage areas. The implementation of flow optimisation and lean layouts reduces the amount of labour force, material movements, and other unproductive movements around warehouses.

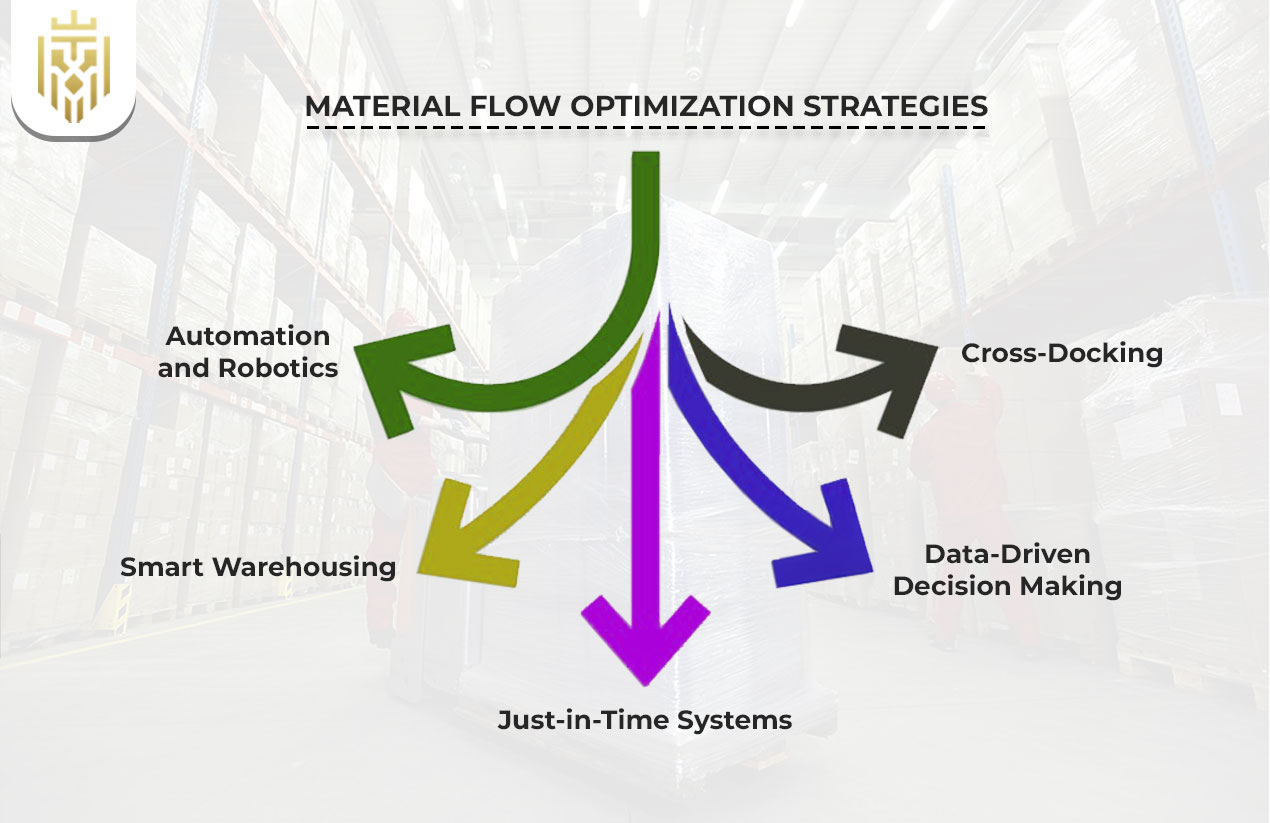

Material Flow Optimization Strategies

Proper flow optimisation can assist in the minimisation of waste, handling, and speeding up of operations. Automation, better layouts, and real-time monitoring are used in organisations to simplify routes and ease movement. Adding material flow network design concepts and sophisticated planning systems will enhance flexibility and reinforce operational performance between receiving and outbound logistics.

Automation and Robotics

Automation increases the speed and minimises errors. Under clever material circulation in production, robotics convey goods securely, enhancing uniformity and reducing the amount of manual labour. The integrated sensors allow material flow tracking in real-time, thereby enhancing accuracy in warehouse and production systems.

Smart Warehousing

Smart warehouses are monitored with the help of the IoT, RFID, and smart conveyors. Improved warehouse management systems make the sorting and storage automatic. The systems enhance the supply chain optimisation, as they guarantee faster picking, efficient use of space, and reduced disruptions in the operations.

Just-in-Time Systems

JIT also helps to minimise inventory of buffers and concentrate on the delivery of goods at the time of need. Timely deliveries are achieved through strong inventory control and coordination with suppliers. The model facilitates lean operations to reduce waste and enhance responsiveness to production.

Data-Driven Decision Making

Predictions and accuracy of operations are enhanced using data analytics. Demand forecasting and efficiency planning are supported by using AI. The continuous improvement of companies to improve the flow of materials is achieved by studying the procurement patterns, production cycles, and transport routes.

Cross-Docking

Cross-docking enhances the flow of goods through the absence of long-term storage of goods as they transfer from inbound to outbound vehicles. This technique helps to improve the speed of the processes, eliminates the handling and use of less space in the warehouses. It enhances logistic efficiency and coincides with logistic management plans that are supply chain-specific to minimise lead time and transport coordination across supply networks.

Material Flow Efficiency

Efficiency in material flow also makes sure that goods flow with ease through all the working processes and delays are minimised and throughput enhanced. Firms employ inventory management, demand-style planning and digital movement tracking to streamline movement. Well-coordinated warehouses and less idle time aid in the efficiency of material flow to customers as well as cost performance throughout supplying networks.

Inventory Turnover

Inventory turnover indicates the rate at which inventory is sold and replaced and has an impact on material flow in a supply chain success. Increased turnover enhances better cash flow and minimised holding costs. Companies monitor the rates of movement, stream purchase cycles and practice demand forecasting to prevent overstock or shortages to maintain a perfect balance of resource planning and storage.

On-Time Availability

Real-time availability also marks availability so that material is available when needed, facilitating the flow of materials in the manufacturing process. It is based on a proper production schedule, suppliers and coordinated operations in the warehouse. Firms enhance the integration of supplies and embrace technology-based alerts to keep pace with stock and eliminate downtimes in high-demand business settings.

Material Handling Cost

The measures of material handling cost include the labour, warehousing and equipment cost of transporting materials. Optimising the flow minimises the frequency of movements, conserves labour and guarantees the quality of products. The automation, planning of material flow pattern, and better planning of their layout reduce the cost without interrupting the flow of materials and the high level of services across the plants.

Throughput Time

Throughput time is an indicator of the length of time that material remains in the process in order to move through the process and influences the speed at which the process is completed. The minimisation of the number of bottlenecks, the design of the network of material flows, and the acceleration of the decision-making process increase performance. Companies use lean methodologies and live tracking of material flow to hasten the process and enhance the responsiveness of complex supply processes.

Challenges in Managing Material Flow

The challenges of managing material flow include such complexities as supplier delays, faulty forecasts, and warehouse bottlenecks. Poor visibility and old systems reduce responsiveness. Good warehouse management, joint planning and responsive digital systems enhance control to facilitate quicker decision-making and optimal supply movement with the least disruptions and wastages throughout the operations.

Poor Communication Between Supply Partners

Failure of the communication chain disturbs the flow of materials, causing delays and failure. Easy sharing of forecasts, inventory information, and shipment reports is facilitative. The adoption of integrated systems will maximise supply, improve trust, and ensure there is clear coordination among the partners to ensure goods are transported as scheduled with the minimum amount of disruptions.

Lack of Visibility across Multi-tier Suppliers

The lack of visibility among various suppliers has a consequence on continuity and a weak response in response to demand changes. It is important to introduce a system that secures transparency through real-time material flow tracking tools. An active tracking process can avoid the deficit and enhance better planning, contributing to quicker reaction and easier management of the global and intricate supply patterns.

Inaccurate Demand Forecasting

Ineffective forecasting issues material movement, thus causing stock overage or scarcity. The companies balance using analytics-based tools of demand forecasting, communication with suppliers and analysis of the past. Accurate forecasting will enhance better coordination at the warehouse, standardisation of the procurement cycles and harmony of supplier planning to ensure uniform operations.

Inefficient Logistics Management

Poor logistics management impacts the timing of transport, space scheduling and coordinated movement schedules and delays movement. Better route planning, better supplication of material, and incorporation of sophisticated systems contribute to the reliability of material flow. Real-time visibility and continuous assessment assist in reducing transport costs and minimising the risk of disruption along supply lines.

Inflexible Systems

Rigid systems find it difficult to adjust to the changes in the volume and supply interruptions, which negatively affect the efficiency of the material flow. Scalable platforms, automated handling, and agile planning enhance responsiveness and performance. Upgrades in modern technology facilitate the changes in resource planning requirements and reinforce the reliability in end-to-end operations in any dynamic environment.

FAQs

1) What is the main purpose of material flow analysis?

To assess and optimise the flow of materials in a system and enhance the efficiency, minimise waste, and assist with improved planning, resource utilisation, and sustainability choices in supply chain and production activities.

2) What role does forecasting play in material flow management?

The future demand is forecasted to aid in planning inventory, production, and distributing resources to ensure there is a smooth flow of materials and prevent shortages and excess stock, and the same supply chains will perform consistently.

3) What are the benefits of sustainable material flow practices?

They reduce waste, use of resources and costs, promote the concept of the circular economy; and achieve supply chain efficiency besides promoting environmental responsibility and business sustainability in the long term.

4) How is real-time tracking used in material flow?

The real-time tracking and monitoring provide the ability to track inventory movements immediately, enhancing accuracy, minimising delays, and improving visibility, decision optimisation, and coordination of logistics, warehouse operations, and production schedules.