Understanding Lean Supply Chain

A lean supply chain seeks to attain topmost efficiency alongside the least possible waste. This concept is rooted in lean manufacturing, where every activity is intended to provide the customer with the maximum value using the least amount of resources. Through a lean supply chain, companies aim at establishing a hassle-free movement of goods, services, and information.

The main objective is to enhance agility, cut down waste, and provide customer delight without the need for doing away with spending or stocking up excess goods. Every part of the supply chain in this method, starting from buying to the last delivery, is measured according to the amount of value it brings. The activities that do not add value are marked out and discarded through an uninterrupted process of assessment.

The lean supply chain is not only a cost reduction method but also a discipline, a collaboration, and continuous improvement to the philosophy perspective. It sets the emphasis on doing more with less and, at the same time, of course, keeping the quality and customer trust.

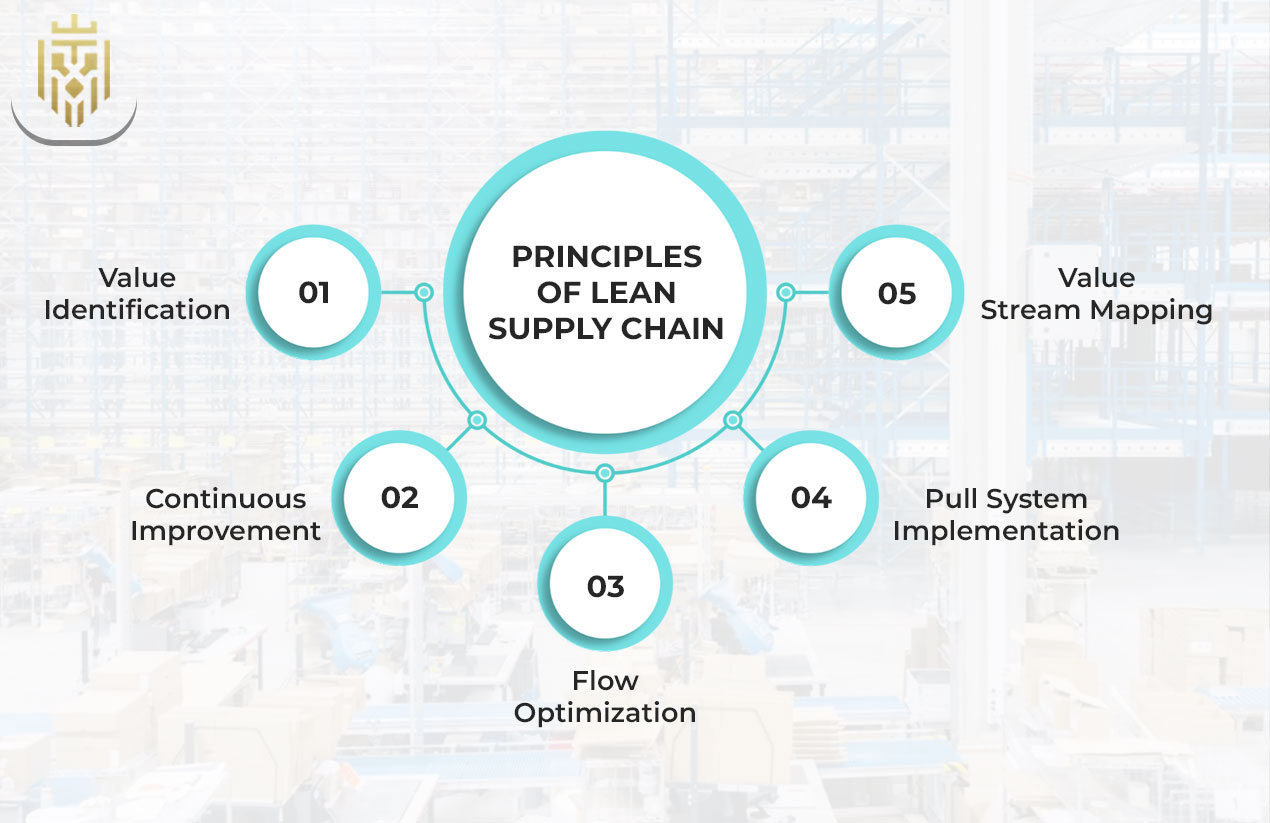

Principles of Lean Supply Chain

The lean supply chain model is governed by key principles that guide organisations towards operational excellence. These principles collectively ensure that efficiency and customer value remain at the heart of every process.

Value Identification

One of the most important aspects of lean thinking is identifying value. This means learning the exact things that the customer cherishes and coming up with ways that consist of delivering only those processes. In other words, it is about the elimination of any steps, use of materials, or incurring costs that do not have a role in the product’s worth. By unambiguously determining the value, organisations can better manage their resources, which is going to be very advantageous, as every aligned customer expectation is going to be with business objectives.

Continuous Improvement

Continuous improvement, also called ‘kaizen’, is a part of lean supply chain management. It focuses on tiny adaptations over the years instead of large ones. All workers are encouraged to suggest improvements, thus making it a place where innovations come and go as part of daily operations. This ongoing effort to improve things leads to more production, less waste, and a workforce that is always behind and enthusiastic to go.

Flow Optimisation

Optimising the flow of materials and information guarantees that these will be movable alongside the supply chain and without the toll of interruptions or delays. A flow that has been well-optimised bottlenecks, lead times are reduced and products reaching customers are faster. The principle also promotes the eradication of waiting times, uncalled for transport, and redundant routines, thus finally leading to an operation that is both predictable and responsive as well.

Pull System Implementation

The pull system changes forecast-driven production to demand-driven operations. Instead of huge quantities being produced in advance, goods will be manufactured or moved only when there is actual customer demand. This situation prevents overproduction and minimizes the chances of stock not being sold before it gets old, at the same time, production is more tightly aligned with the market’s needs. It creates a responsive system that adapts quickly to fluctuations in demand while maintaining efficiency.

Value Stream Mapping

Value stream mapping is a visual tool used to analyse, design, and improve the flow of materials and information required to deliver a product or service. It helps organisations identify waste and inefficiencies in the supply chain. By mapping the entire process from start to finish, companies can see where time and resources are being lost and implement targeted improvements. This method ensures all functions work together toward a shared goal of operational excellence.

Understanding Circular Supply Chain

A circular supply chain is based on the idea of sustainability and regeneration. The traditional linear model, which was based on a “take, make, dispose” pattern, has been totally replaced by the circular model that wants to close the loop by keeping materials and products in use for as long as possible.

The main idea behind the circular supply chain is that waste is turned into a resource, and it encourages repair, reuse, recycling, and regeneration. The circular supply chain changes the way companies see production, consumption, and waste. It is environmentally responsible but economically valuable at the same time.

The companies that are using the circular supply chain model are changing their product design, sourcing, and distribution strategies in order to minimize environmental impact. They are not only safeguarding the planet by focusing on sustainability but also opening up avenues for innovation and long-term profitability that are economical for them.

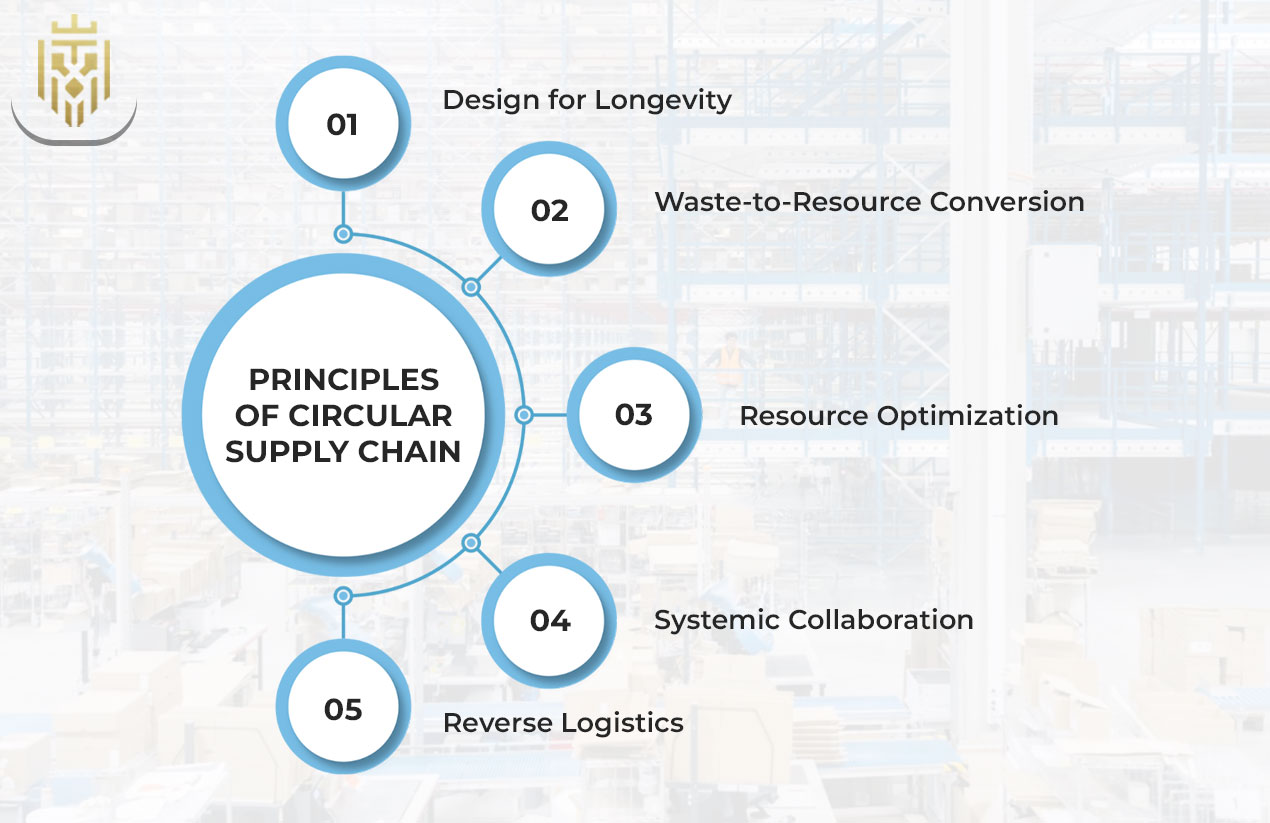

Principles of Circular Supply Chain

The circular supply chain is guided by principles that focus on resource efficiency, collaboration, and lifecycle thinking. These principles ensure that sustainability becomes a continuous process rather than a one-time initiative.

Design for Longevity

The process of designing for longevity makes sure that products are not just made to be used for a specific time; instead, they are products that give the manufacturer the choice to either reuse or recycle them later. This introduces less waste, lower demand for replacements, and happier customers. Products that last long also serve the business more sustainably by cutting down on the dependency on resources and the waste produced.

Waste-to-Resource Conversion

The hallmark of a circular supply chain and one of its major characteristics is the disposal of waste and its turning into a resource that can be used. The materials that would otherwise go to the dumps are either restored, reused, or recycled. This method not only curtails the consumption of the raw material but also lowers the carbon footprint and paves the way for a greener economy. By closing the loop for materials, businesses can reduce costs and environmental impact at the same time.

Resource Optimization

Resource optimisation is the process of turning every input of material and energy into something that is not just used but also saved for later. Minimising the consumption of the resources and enhancing the quality of the available ones are the goals that companies have to achieve. This enhances cost-effectiveness and at the same time, the company’s commitment to the environment is reinforced due to lesser depletion and pollution.

Systemic Collaboration

Collaboration is one of the pillars supporting the circular supply chains that is needed everywhere in the ecosystem—from manufacturers to suppliers and customers to recyclers, all must join hands to keep the flow of materials going. Great communication and taking shared responsibility open up new areas for getting the best out of the products and the materials. This holistic approach guarantees that sustainability will be present in every step of the operation.

Reverse Logistics

Reverse logistics plays a vital role in enabling circular practices. It manages the movement of used products back through the supply chain for repair, remanufacture, or recycling. By creating efficient return and recovery systems, businesses can reclaim valuable materials while reducing waste and landfill use. Reverse logistics also improves customer engagement by offering take-back schemes and sustainable disposal options.

Differences Between Lean and Circular Supply Chain

Lean and circular supply chains are the two ways of looking at the same problem, i.e., how to make the supply chain more efficient and less wasteful, but they differ in their purpose and method. Lean thinking concentrates on process efficiency; circular thinking, on the other hand, is all about environmental sustainability and resource renewal. These define the two main philosophies of supply chain management, which are, therefore, complementary yet different.

Objective

The main goals of lean supply chains are to operationalize waste reduction, enhance speed, and lower costs while at the same time keeping quality. The opposite of waste and resource circulation are the twin objectives of circular supply chains as they want to completely design out waste streams while creating regenerative loops where resources are continuously circulated.

Focus Area

Lean management focuses on production efficiency and cost reduction as its primary targets. It makes sure that no step of the process is performed unless it brings value to the customer. The circular approach manages materials and their life cycles, making sure that every aspect of the product—from design to disposal—is eco-friendly and resource-saving.

Lifecycle Perspective

Lean supply chains usually work within a linear manufacturing scheme, whereby products proceed from production to consumption. By contrast, circular systems take a broader view and also consider customer return, reuse, repair, recycling, and the recovery of material resources, therefore allowing resources to be invaluable through many lifecycles.

Core Philosophy

The core philosophy of lean supply chains is the elimination of waste as a means to improve better operational performance and, consequently, greater profitability. The regeneration—that is the creation of systems which restore and renew natural as well as material resources instead of depleting them—is the foundation of the circular supply chain’s philosophy.

Outcome

The lean approach results in streamlined processes, lower costs, and improved responsiveness to customer demand. The circular approach results in sustainable growth, lower environmental impact, and stronger alignment with corporate social responsibility goals.

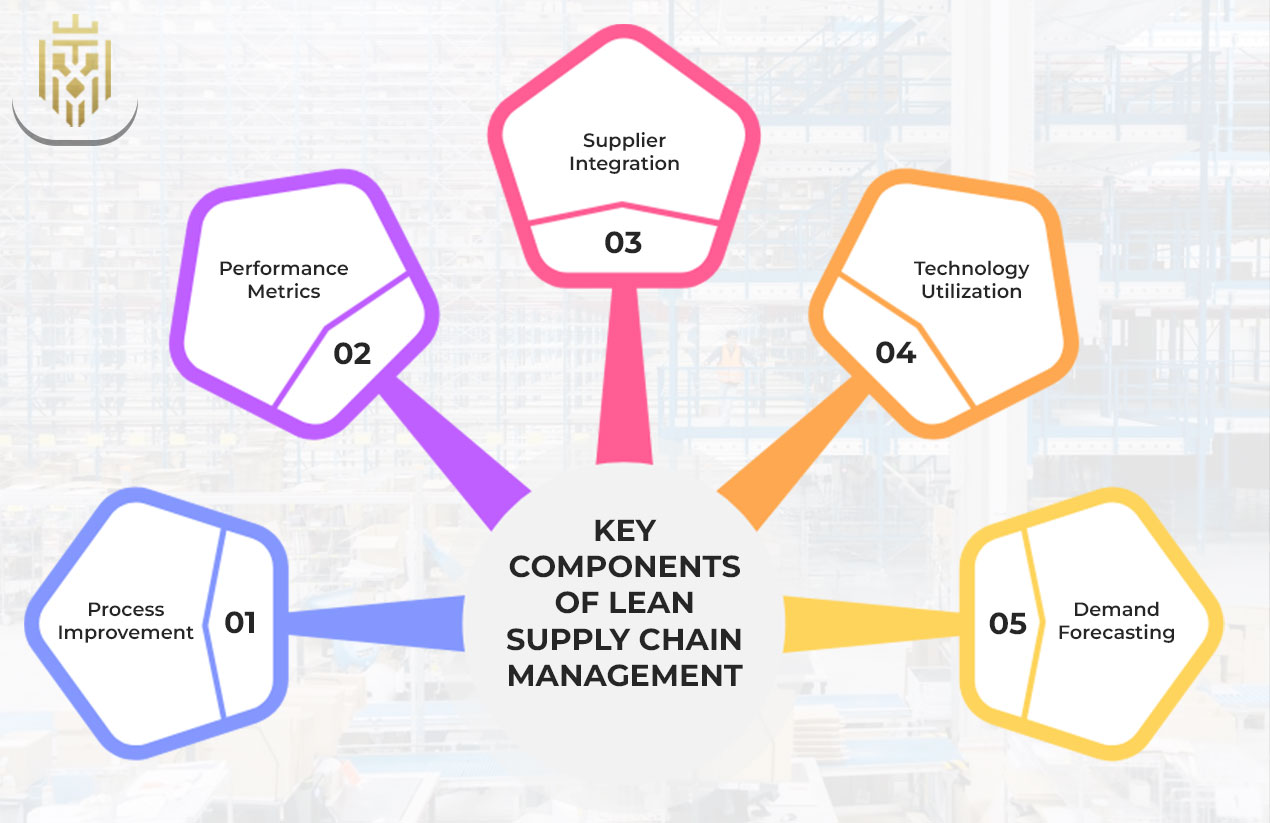

Key Components of Lean Supply Chain Management

Lean supply chain management depends on continuous improvement, collaboration, and data-driven decision-making. Its components ensure efficiency at every operational level, driving measurable performance gains.

Process Improvement

Process improvement guarantees that every inefficiency is discovered and solved instantly. Each business step is assessed to prove it adds value to the customer. They apply the resources of feedback and analytics to increase the efficiency of workflows, cut the time down on delays, and keep the quality uniform.

Performance Metrics

Performance metrics are utilized to follow the course of productivity, lead times, and cost efficiency. By consistently measuring the outcomes, the businesses can spot the gaps and areas that need improvement. The same metrics also serve to continuously improve the processes through the application of data-driven strategies.

Supplier Integration

Supplier integration facilitates synchronization among the production and sourcing departments. The supplier relationship that is built up closely guarantees that shipments and the quality of goods are kept at a level that is consistent and both are timely. Joint planning and order forecasting make the reliability stronger and at the same time, they cut down the risks of stockouts or overproduction.

Technology Utilization

Contemporary lean supply chains are largely dependent on technology for monitoring and managing the complex operations involved. Digital tools, automation, and data analytics are the ones that provide the visibility of the whole network. The combination of tracking in real-time, AI forecasting, and predictive maintenance makes the decision-making process not only faster but also more accurate and effective.

Demand Forecasting

With demand forecasting, firms can know what the customers will need even if they do not express it. Utilizing past data together with predictive analytics, the companies can modify their production timelines and storage levels. Furthermore, with precise forecasting, there is assured flexibility and less over production wastage.

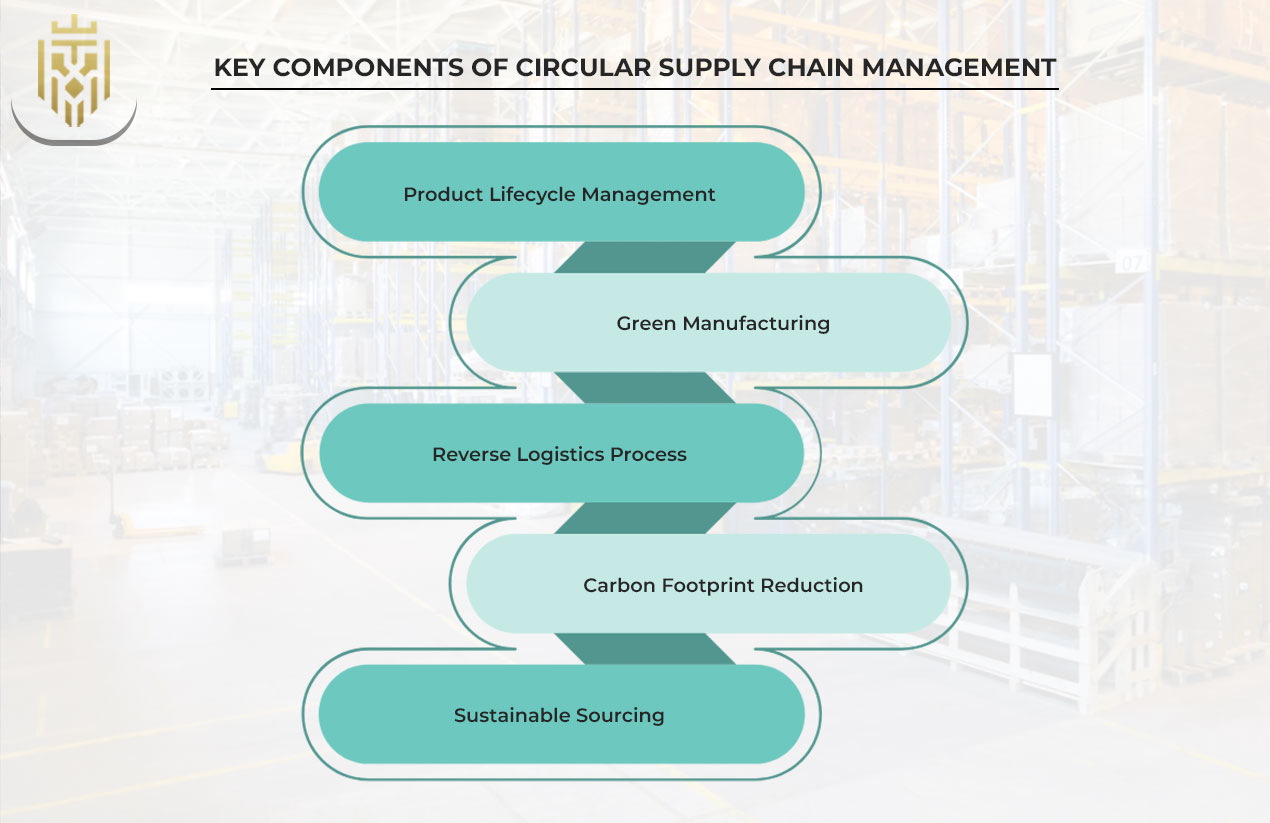

Key Components of Circular Supply Chain Management

Circular supply chain management focuses on maintaining material value, extending product life, and promoting sustainability at every stage of production and distribution.

Product Lifecycle Management

Product lifecycle management connects together the design, production, and post-use processes. It makes sure that the whole product’s life is optimised for sustainability and tracking the whole lifecycle leads to better choices in terms of materials, repair and recycling.

Green Manufacturing

Green manufacturing means to cut down on emissions and use less energy during production. This practice involves the utilisation of renewable energy sources, waste minimisation tactics, and eco-friendly materials. The way this method has no negative effect on the environment at the same time ensures the compliance with the demanded standards in terms of sustainability.

Reverse Logistics Process

Reverse logistics gives the opportunity for the companies to get back their products and materials once they are not used anymore. Efficient return systems are great for the company to either refurbish, resell or recycle the returned goods, thus turning waste into inputs with value. The process not only helps in becoming more sustainable but also in recovering costs at the same time.

Carbon Footprint Reduction

Circular supply chains are all about the reduction of greenhouse gas emissions through better transportation, energy-efficient practices and sourcing that is sustainable. Along with the reduction of the carbon footprint, the companies also gain the advantage of being able to meet the regulatory requirements and enhancing their brand credibility.

Sustainable Sourcing

Sustainable sourcing practices are directing the suppliers towards being ethical and eco-friendly. The assessment of the impact on environment, people and material traceability is part of the evaluation process. Responsible sourcing thus gives rise to and supports the attainment of social and environmental sustainability goals at the same time.

Integrating Lean and Circular Supply Chain

Integrating lean and circular supply chain principles creates a balanced system that maximises efficiency and sustainability simultaneously. While lean ensures operational excellence, circular ensures environmental responsibility. Together, they help businesses achieve long-term resilience and value creation.

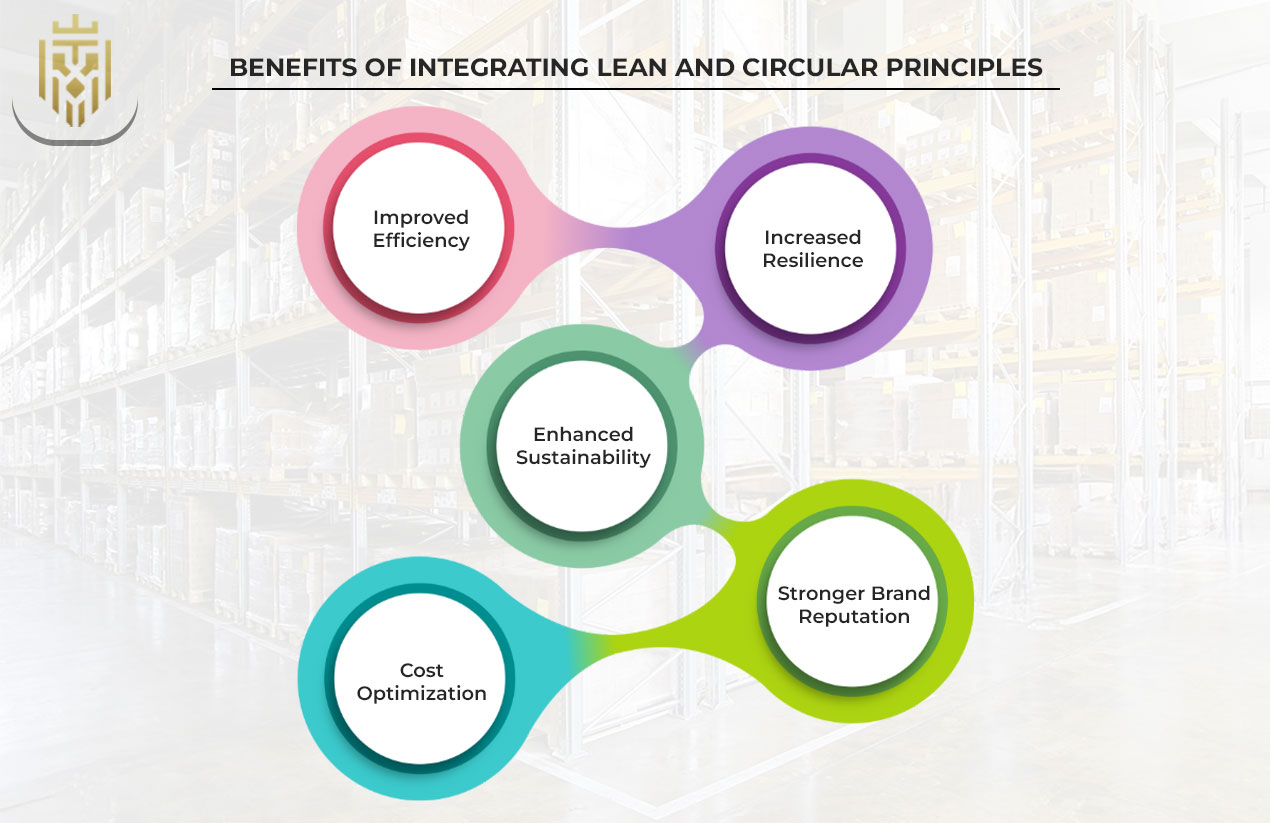

Benefits of Integrating Lean and Circular Principles

Combining both approaches strengthens overall performance and builds a future-ready supply chain that benefits both business and the planet.

Improved Efficiency

The companies that apply lean tools to the circular systems are able to facilitate and simplify the recycling and recovery processes. This leads to elimination of redundancy, better resource utilization, and faster operations through all the supply chain stages.

Increased Resilience

The combination of both approaches to the production and resource regeneration improves the resilience against the disruptions. The business stays flexible and strong enough to face the market fluctuations or supply shortages if they are optimized in both production and resource regeneration.

Enhanced Sustainability

Lean and circular principles together ensure waste is minimized to the extent that materials are reused continuously. The combination of these three factors could be viewed as a highly sustainable system preventing the environment from further damage and at the same time allowing the company to earn profits.

Stronger Brand Reputation

Businesses that are adopting integrated lean and circular strategies are often recognized as responsible industry leaders. Such a reputation is attracting customers, investors, and partners that put a premium on sustainable practices and ethical business conduct.

Cost Optimization

The integration permits the companies to recover the materials and at the same time to streamline the processes thus allowing the reduction of production and waste management costs. The outcome is that the profit margins are higher while the environmental expenses are lower.

Real-World Applications

Industries across the world are successfully adopting lean and circular supply chain principles. Their combination is redefining production standards, reducing waste, and improving sustainability across multiple sectors.

Automotive Industry

Lean principles are implemented in the automotive industry through production techniques that ensure only the required parts are made and at the right time, which consequently eliminates waste due to excess inventory and makes assembly very efficient. The industry is also employing circular practices like metal parts recycling, battery reuse, and material repurposing from end-of-life vehicles which all together form a closed and sustainable loop.

Packaging Sector

The packaging industry is moving towards lean production wherein the use of redundant materials is reduced and at the same time implementing circular models like the introduction of biodegradable packaging and recycling systems. These methods not only decrease the cost of production but also contribute to better environmental compliance.

Consumer Electronics

Lean approach used in the electronics industry not only leads to greater manufacturing precision and less machine downtime but also to the recovery, refurbishment, and recycling of parts made possible by circular principles. The mix of these two approaches results in less e-waste and greater product lifecycle value.

Textile Industry

The textile industry applies lean efficiency together with circular innovation by streamlining the production of fabrics and introducing recycling systems for these fabrics. Many fashion brands are already advocating for repair, reuse, and eco-friendly sourcing in order to fulfill the requirements of both the planet and the consumers.

FAQs

1) How does a circular supply chain differ from a closed-loop supply chain?

The two supply chain models try to minimize waste, but they differ in their approaches. A circular supply chain concentrates on material regeneration in all industries, whereas a closed-loop supply chain majorly deals with product returns within a single production cycle. The circular model not only supports partnerships between companies but also generates a common good through the circulation of resources.

2) Can lean and circular principles be applied together?

The answer is yes, lean and circular principles in the supply chain are a perfect match. Lean leads to the companies becoming more efficient in their operation and better in their resource allocation, while the circular one gives the businesses the guarantee of long-term sustainability. Together, they can make the firms environmentally friendly and socially responsible while still being profitable.

3) What role does digital technology play in circular supply chain management?

Digital technologies, including artificial intelligence, IoT, and blockchain, are essential for managing the entire life cycle of materials, keeping an eye on carbon footprints, and efficiently utilizing resources. They are the backbone of the circular supply chain in that they are the companies’ eyes and ears, providing evidence that the companies’ claims regarding sustainability are indeed true.

4) What are the main challenges in implementing a lean supply chain?

Lean supply chain management is often met with resistance, and the lack of adequate training and visibility of data are two main issues that can cause its implementation to be difficult. It is necessary to change the company culture such that every employee is concerned about efficiency and is open to learning. Winning over the management, creating proper channels of communication, and flexibility in process evaluation are some of the factors that will determine your success

5) How can companies measure the success of lean or circular supply chain initiatives?

Success is measured through multiple indicators, including cost reduction, waste minimisation, improved customer satisfaction, and reduced environmental impact. Tracking metrics such as energy consumption, recycling rates, lead times, and profit margins helps businesses assess performance and refine strategies for sustained growth.