What is a Centralized Warehouse?

A centralized warehouse is a one-point warehouse where products are stored and distributed to an entire organization. The model improves management of inventory and streamlines the work of warehouses, as well as making it easier to manage resources, which are all under one roof. It is best when a company wants uniformity and economical operation of the supply chain.

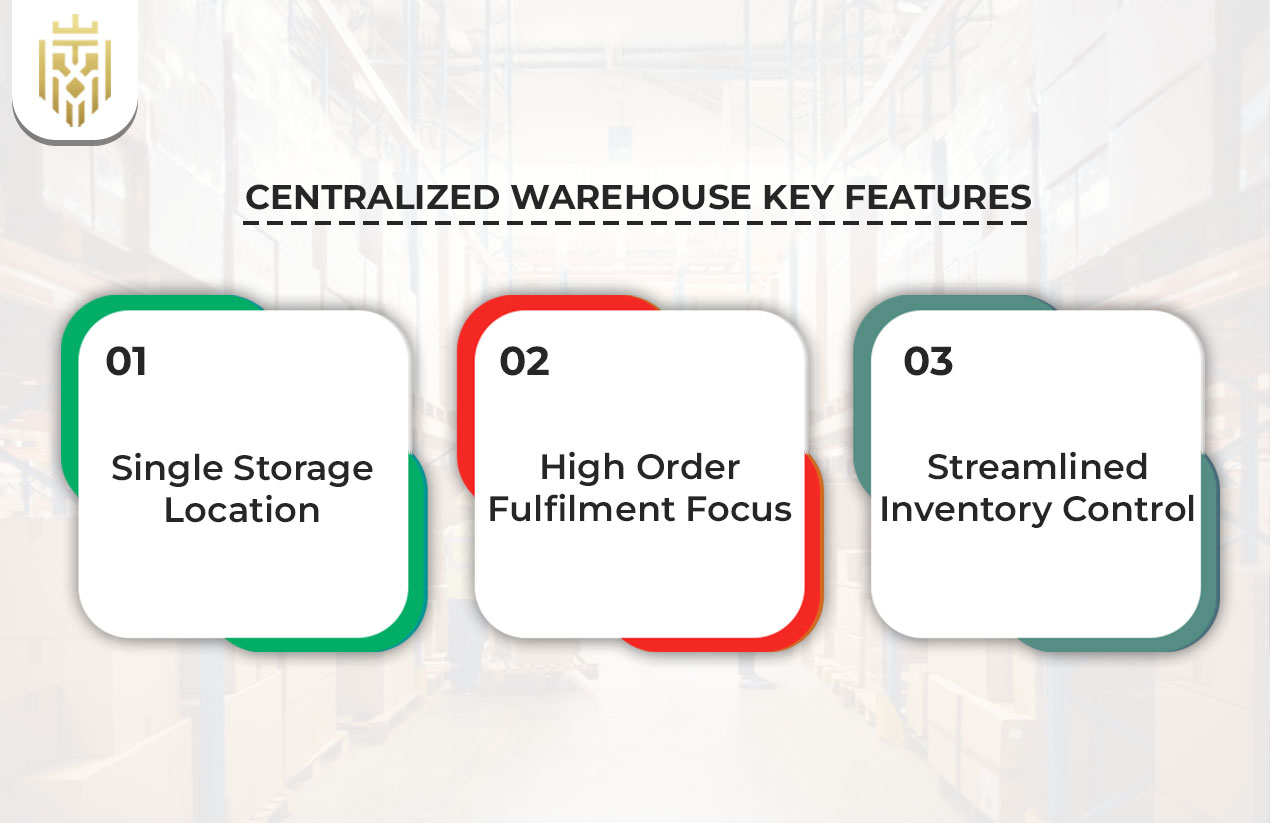

Key Features

The key features of a centralized warehouse system include unified management, streamlined data handling, and simplified distribution network processes. These attributes enhance supply management by incorporating procurement, warehousing, and dispatching activities in a single hub, facilitating easy order-delivery and effective coordination of operations within companies.

Single Storage Location

The centralized warehouse is run out of just one warehouse unit, where inventory is easily controlled, and space is utilised optimally. Stock centralization makes the supply an effective management option and keeps stocks efficiently monitored and supplied to help businesses enhance precision and efficiency in their supply chain network.

High Order Fulfilment Focus

The centralized distribution network emphasises efficient order fulfillment. The orders are made at a central point, which enhances faster delivery and reduces errors. This single solution improves customer satisfaction and helps in having predictable timelines in the complicated operations of the warehouse.

Streamlined Inventory Control

A centralized warehouse system improves inventory control by consolidating all data into one management point. This facilitates improved predictions, tracking and decision-making, effective supply management and optimal performance of distribution networks in different regions.

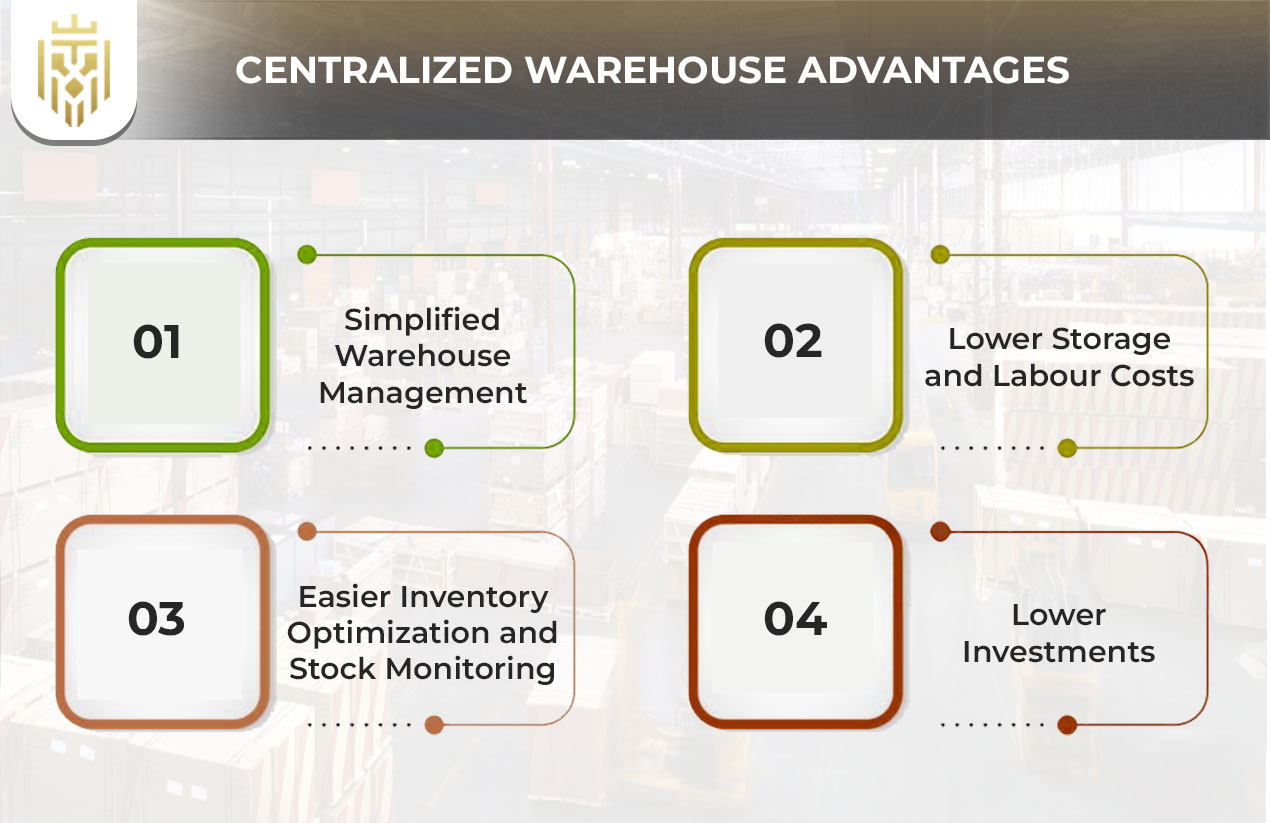

Advantages of Centralized Warehouse

The advantages of centralized warehouse management are simplified coordination, cost reduction and better visibility throughout the supply chain. A centralized organization improves the accuracy of stocks and resource, use better providing organizations with a greater basis for managing their supply efficiently, and maintaining a stable warehouse operation.

Simplified Warehouse Management

A centralized warehouse system simplifies warehouse operations by combining supervision, dispatch, and maintenance in one place. This enhances coordination and accelerates order fulfillment enabling managers to have greate

r control of resources and performance throughout the supply chain.

Lower Storage and Labour Costs

The warehouse has a central location which saves on various facility costs. The single storage point would need less workforce and less energy expenditure. This supports streamlined supply management and minimises waste while maintaining high operational efficiency in a centralized distribution network.

Easier Inventory Optimization and Stock Monitoring

In a centralized warehouse system, monitoring stock is simpler. Managers are able to maximise inventory, minimise surplus, and enhance accuracy in forecasting. Improved inventory management leads to effective supply chain planning and helps utilize the available warehouse capacity effectively.

Lower Investments

With a centralized warehouse format, businesses are enjoying reduced infrastructure costs. The pros and cons of centralization depend on business scale, but typically this system demands fewer resources, making it ideal for companies focusing on long-term savings and simplified supply management.

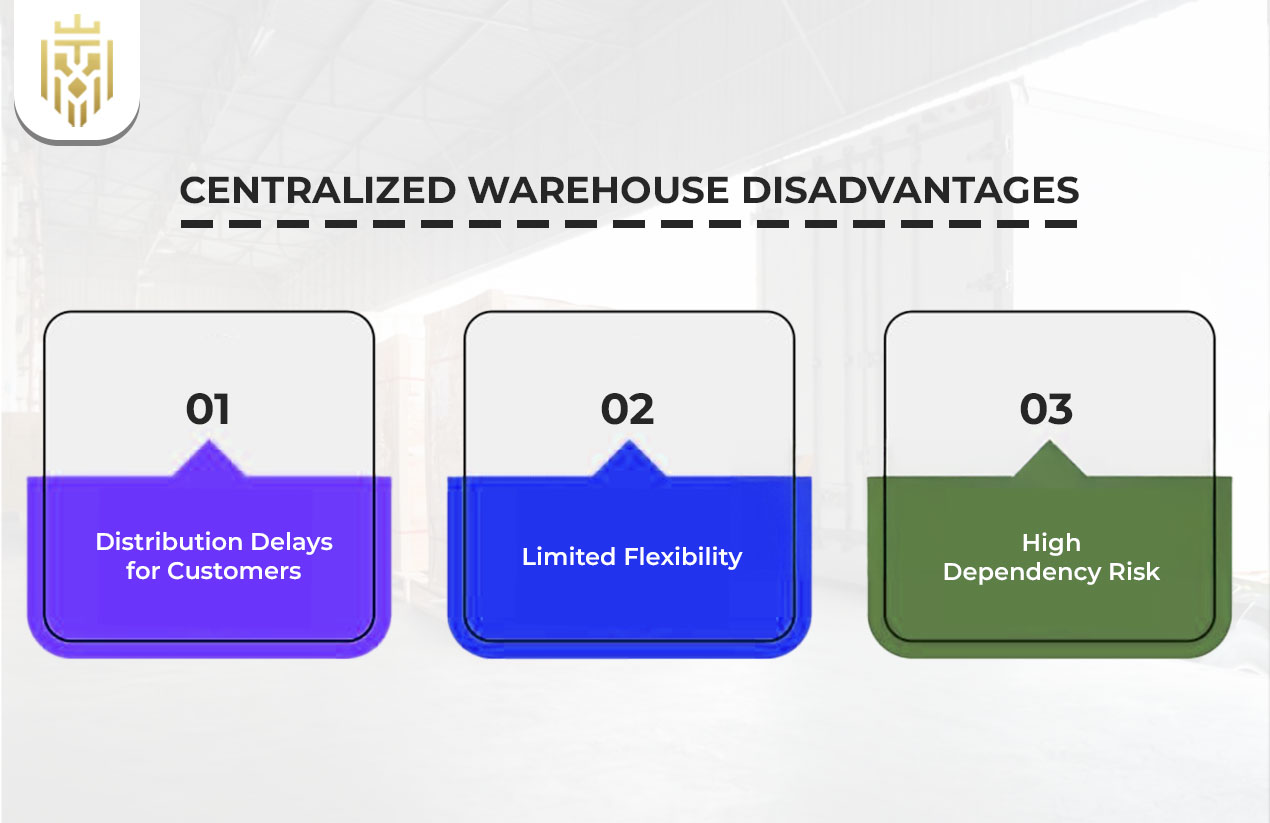

Disadvantages of Centralized Warehouse

A centralized warehouse is efficient but exposes the warehouse to constraints such as dependency and possible delays. The pros and cons of centralization highlight how this model may restrict flexibility and slow response times in distant regions within the distribution network.

Distribution Delays for Customers

A centralized warehouse system may delay shipments for customers far from the central hub. Increased transit distance can impact delivery speed, emphasizing a core difference between centralized and decentralized warehouse systems when it comes to regional service responsiveness.

Limited Flexibility

One storage point restricts regional flexibility over local demand. This can affect the effectiveness of order fulfillment and supply management since a centralized warehouse could not respond very fast to sudden market demand.

High Dependency Risk

A key challenge of the centralized warehouse system is over-reliance on a single hub. Disruptions such as power outages or natural disasters can halt warehouse operations, affecting the entire supply chain and demonstrating a key drawback of centralized vs decentralized logistics.

What is Decentralized Warehouse?

A decentralized warehouse system is one that functions with a series of regional warehouses. This is a methodology that embraces high flexibility, speed of delivery, and user access. Large companies that require regional warehouse operations to satisfy a variety of market needs are often using it in their supply chain.

Key Features

The key features of a decentralized warehouse system include multiple facilities, localised management, and faster responsiveness. This design enables easier order fulfilment, serves a more extensive distribution channel and provides flexible supply management to cater to the diverse geographic needs.

Multiple Warehouses Across Regions

A decentralized distribution network spreads inventory across several storage locations, improving access and delivery speed. It guarantees reliability and increased regional coverage in the supply chain, mitigating the risks of relying on one point.

Good Logistics Network

A decentralized warehouse system relies on a strong distribution network to ensure effective transport between locations. This improves the processes within the warehouse to allow companies to ensure consistent supply and effective order fulfillment to various markets.

Advantages of Decentralized Warehouse

The benefits of decentralized warehouse structure are flexibility, quicker delivery, and nearness to the market. And this strategy contributes to better customer service, supply management, and supply chain resilience by means of distributed risk and local control.

Reduced Delivery Time

The warehouse design is decentralized and reduces transit time by stocking goods close to customers. The result is an increase in speed of delivery, efficient order flow, and better satisfaction among the various market segments, which enhances the entire supply chain.

Reduced Transportation Costs

A decentralized distribution network lowers transportation costs by minimising travel distances. This type of business model is also advantageous to businesses, as they have reduced fuel costs and better logistics coordination which can be scaled using warehouse operations and an optimal way of managing supplies.

Enhanced Market Accessibility

The warehouse decentralization strategy enhances access to the markets and customers. Numerous storage points guarantees the acceleration of service and increased responsiveness, which improves inventory management and helps preserve a more seamless supply chain flow.

More Flexibility

The pros and cons of decentralization reveal higher flexibility in this model. It contributes to the flexibility of regional effects and the needs of different customers, thus aiding companies in maintaining the continuity of operations in different operations in the warehouses.

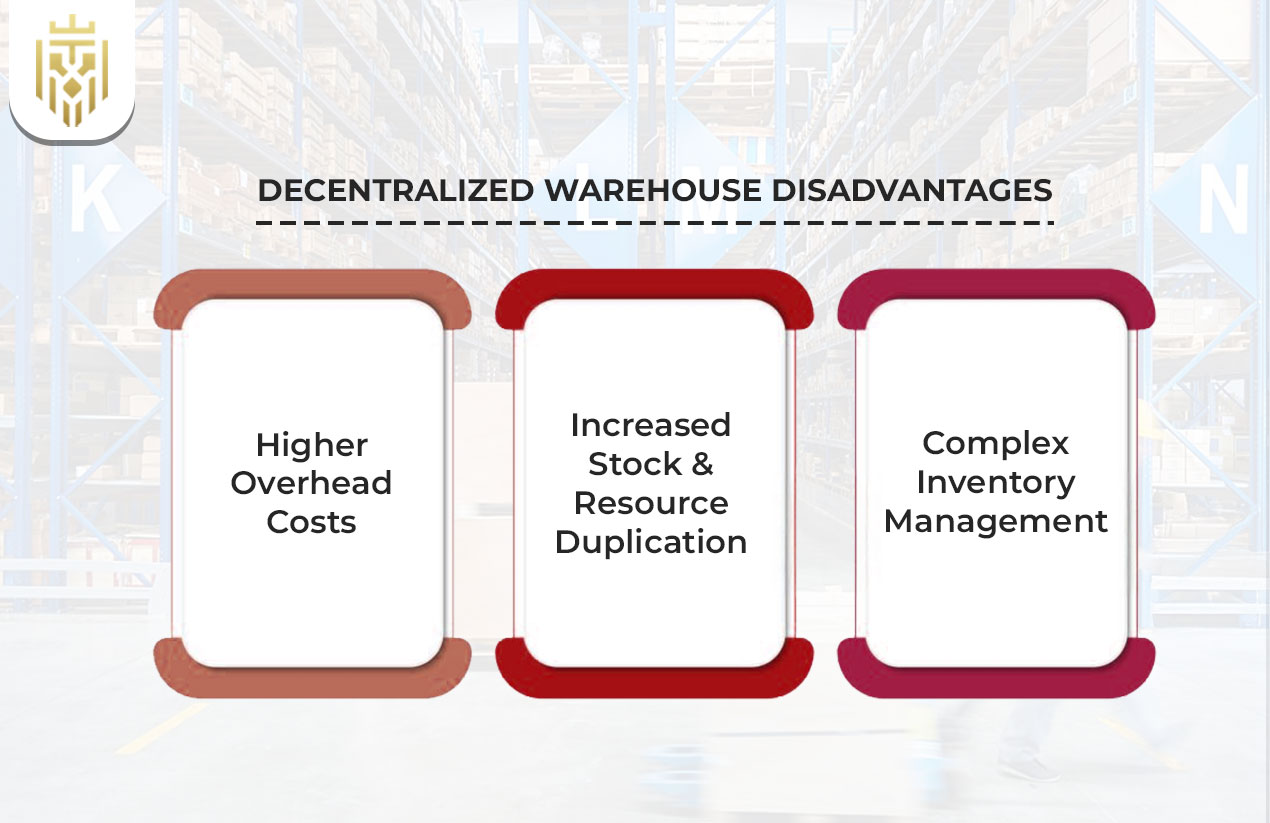

Disadvantages of Decentralized Warehouse

Despite its benefits, a decentralized warehouse system can be costlier and more complex. The coordination and intense investment to maintain control over multiple facilities through various distribution chain strategies are associated with more investment.

Higher Overhead Costs

Having more than one premise increases overheads in terms of rent, personnel and utility. The difference between centralized and decentralized warehouse setups highlights higher expenses but improved local reach, making this model suitable for larger companies.

Increased Stock & Resource Duplication

A non-centralized warehouse usually replicates inventory and tools at different locations. This complicates the supply management and may overstretch the inventory control efficiency of the supply chain.

Complex Inventory Management

There are several storage sites that make it difficult to monitor and report. Managing stock in a decentralized warehouse system requires advanced technology to maintain transparency and coordination across the distribution network and ensure balanced supply management.

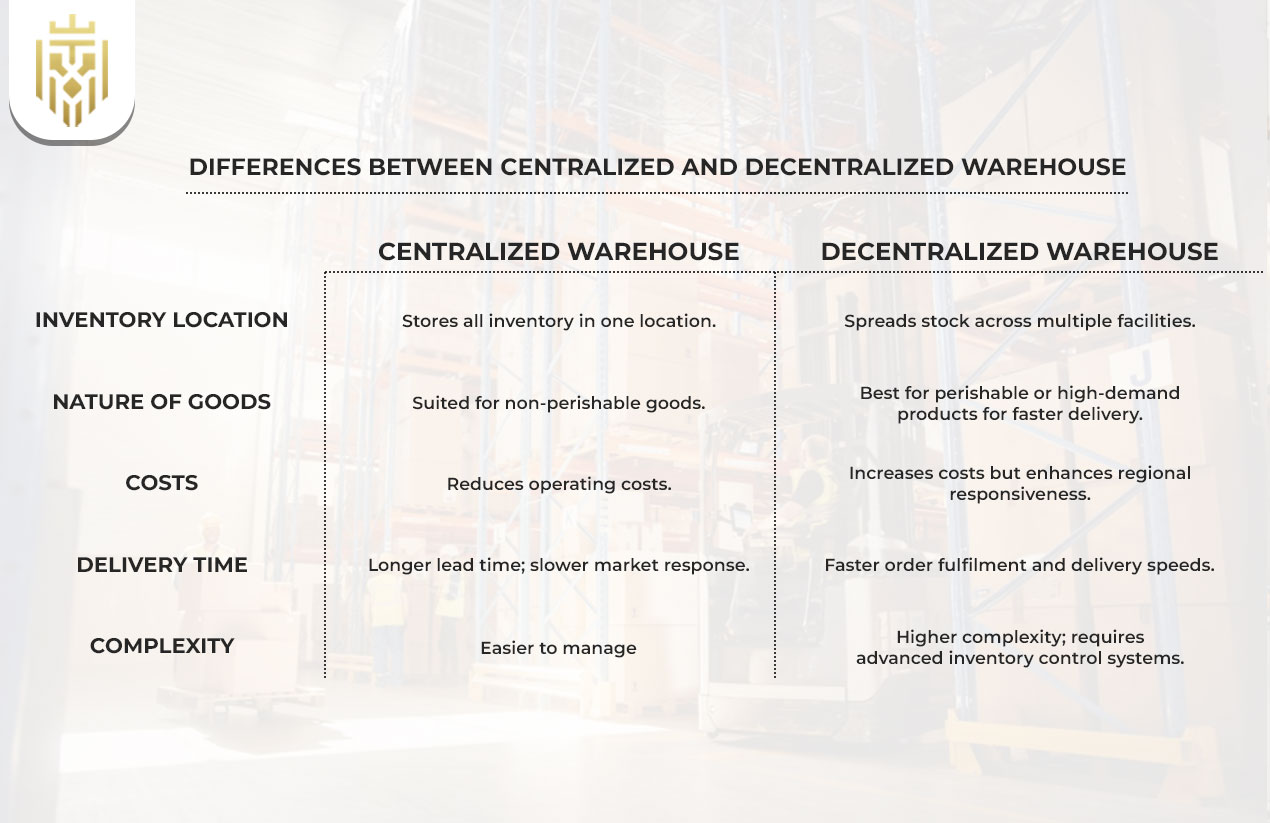

Differences Between Centralized and Decentralized Warehouse

The centralized vs decentralized warehouse comparison highlights how structure affects logistics performance. Understanding the difference between centralized and decentralized warehouse helps organizations align inventory control, order fulfillment, and supply chain responsiveness with their business models and customer needs.

Inventory Location

A centralized warehouse system stores all inventory in one location, while a decentralized warehouse system spreads stock across multiple facilities. The decision affects supply management, transportation expenses and general businesses in the warehouse.

Nature of Goods

Non-perishable goods are better suited for a centralized warehouse, while perishable or high-demand products benefit from a decentralized distribution network, which enhances delivery speed and ensures fresher deliveries.

Costs

A centralized warehouse reduces operating costs, while a decentralized warehouse increases costs and enhances regional responsiveness. Businesses must weigh efficiency versus flexibility when deciding between centralized vs decentralized logistics approaches.

Delivery Time

Decentralized warehouses will provide faster order fulfillment and faster delivery speeds due to their decentralization; whereas centralized warehouses may require more lead time and take longer to respond to the market.

Complexity

A centralized warehouse system is easier to manage, while a decentralized warehouse system involves higher complexity due to multiple storage locations, requiring advanced systems for inventory control and effective supply management.

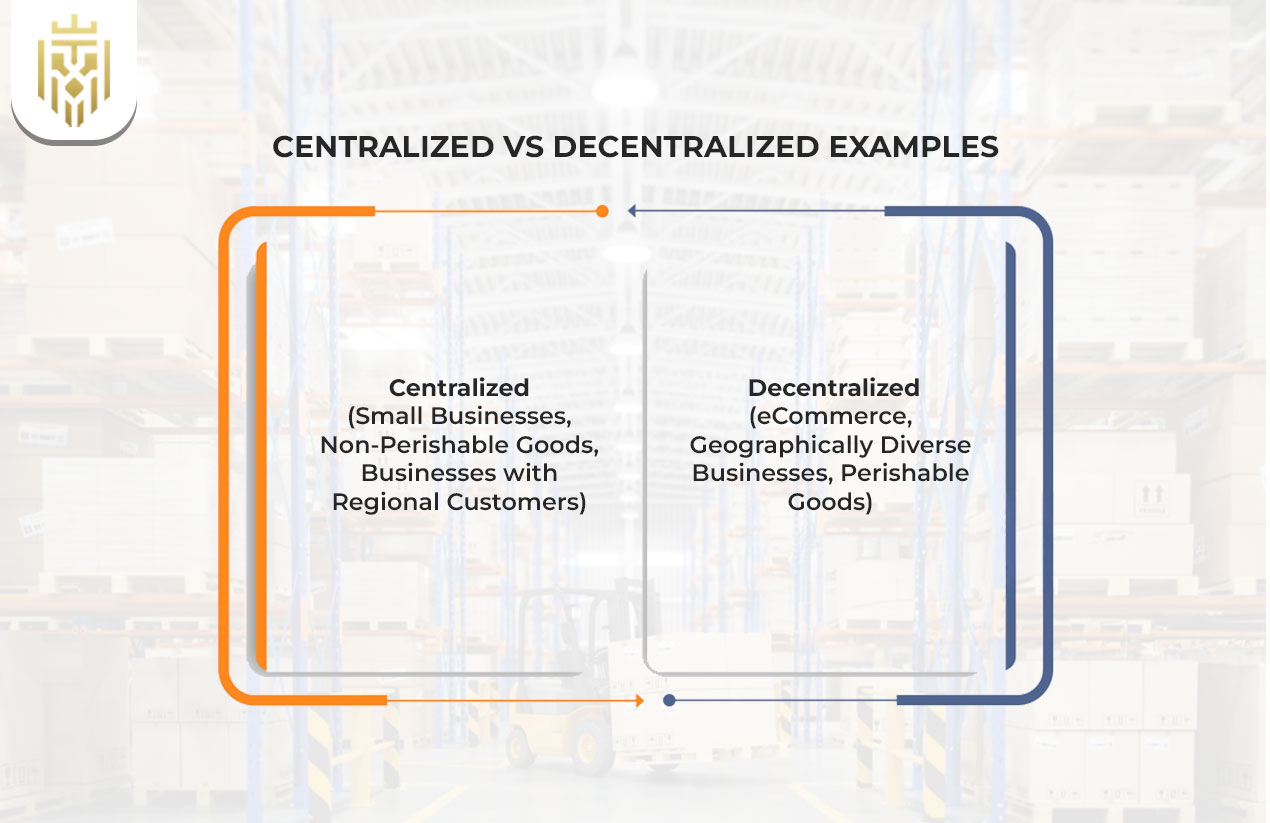

Centralized vs Decentralized Examples

Examples of real-life centralization and decentralization allow businesses to learn about usage. The centralized vs decentralized warehouse comparison illustrates how organization size, product nature, and geographic spread influence supply chain structure and warehouse operations efficiency.

Centralized

A centralized warehouse system consolidates all operations into one facility, ensuring better inventory control, lower costs, and simplified supply management. This model helps in efficiency through centralizing the operations of the warehouse and increasing the coordination among the departments, so it can be recommended to those businesses that tend to concentrate on the costs and operations stability within their supply chain.

Small Businesses

A centralized warehouse is advantageous to small enterprises as it allows them to easily control costs, organise inventory, and better utilize resources. Having all warehouse operations controlled through a single hub makes supply management more effective, cutting back on overheads and ensuring a more effective coordination in the entire supply chain to enable consistent performance.

Non-Perishable Goods

Items like electronics, spare parts, and packaged materials are ideal for a centralized warehouse system because they have longer shelf lives. This arrangement enables safe long-term storage, effective inventory management and streamlined coordination throughout the distribution channel to maintain a consistent supply of the product and manage supply costs effectively.

Businesses with Regional Customers

Companies catering to specific geographic zones often choose a centralized distribution network to maintain operational consistency. This model also provides a smooth flow of operations in the warehouse and reduces duplication in addition to improving a supply chain visibility that enables the businesses to be in control of costs and at the same time provides a reliable supply of orders to the customers in the region.

Decentralized

A decentralized warehouse system distributes inventory across multiple facilities for improved delivery speed and customer access. It improves market sensitivity and enables local supply control and is best suited to large or geographically dispersed businesses requiring flexibility in warehouse operations and quicker regional order fulfillment throughout the supply chain.

eCommerce

eCommerce businesses benefit greatly from a decentralized warehouse system because it brings inventory closer to customers. Such an arrangement gives us quicker order processing, improved delivery time, and higher customer satisfaction and provides more flexibility in warehouse management and increased resiliency in the supply chain network.

Geographically Diverse Businesses

Enterprises with operations across multiple regions rely on a decentralized distribution network for broader market coverage and improved efficiency. It facilitates rapid deliveries, enhanced supply management and responsiveness to local needs, which provide seamless operations involving warehouses throughout the supply chain.

Perishable Goods

Perishable goods such as food and pharmaceuticals thrive in a decentralized warehouse system due to proximity to target markets. This minimizes transit time, preserves freshness and improves inventory control as warehouse operations become more responsive and efficient within a supply chain network that is sensitive to temperature.

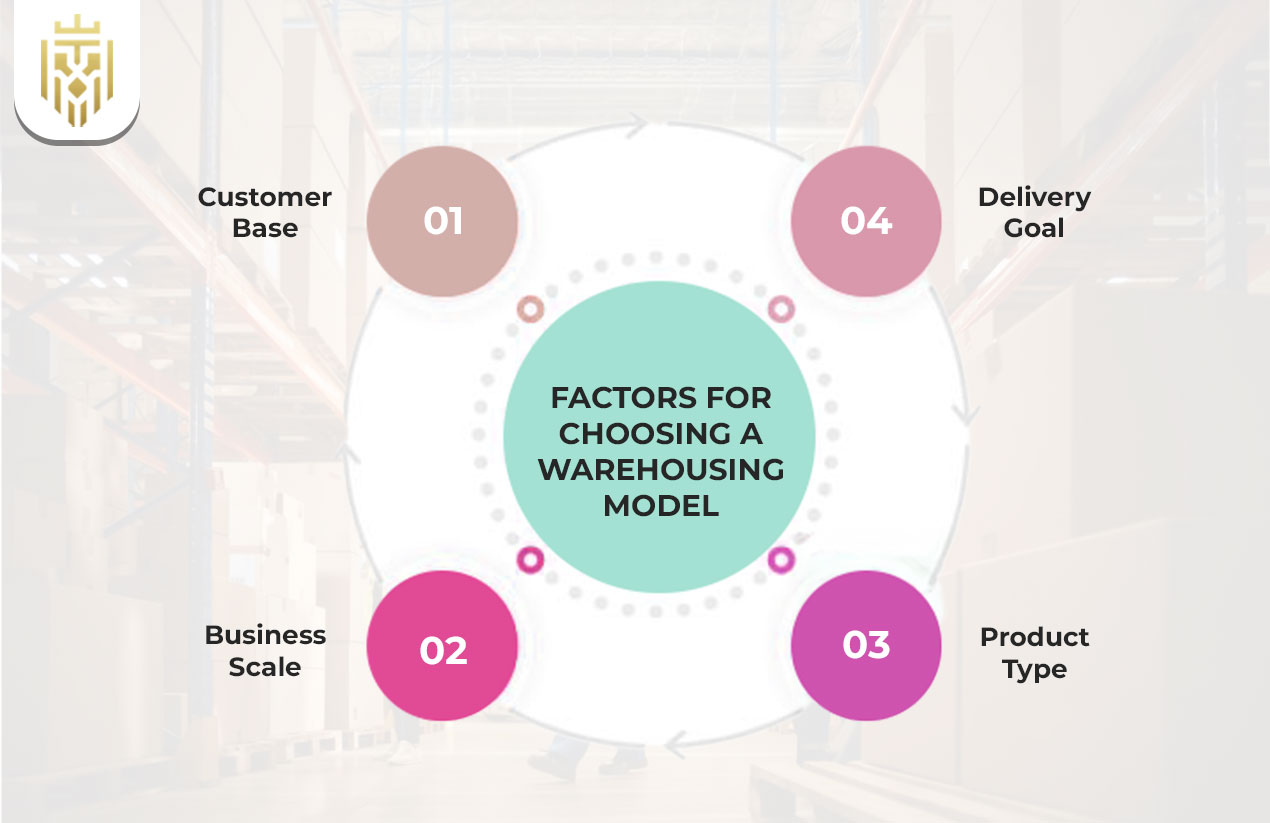

Factors for Choosing a Warehousing Model

Distribution of centralized and decentralized structures depends on supply management, geography and customer expectations. The pros and cons of centralization and the pros and cons of decentralization must be assessed carefully to align with company goals and supply chain dynamics.

Customer Base

A large or dispersed customer base benefits more from a decentralized warehouse, while smaller, localized customers are better served by a centralized distribution network with efficient inventory control and steady delivery speed.

Business Scale

Smaller businesses prefer centralized warehouses for simplicity, while large organizations choose decentralized warehouse systems for scalability and market reach, depending on distribution network requirements.

Product Type

Warehouse structure depends on the nature of goods. Non-perishable products suit a centralized warehouse, while perishable goods require decentralized warehouse systems to maintain freshness and reduce lead time.

Delivery Goal

If the goal is delivery speed, a decentralized distribution network works best. However, for cost efficiency and simplified supply management, a centralized warehouse system is ideal.

FAQs

1. Can businesses shift from centralized to decentralized warehouses over time?

Yes, based on the expansion of the business, the centralised warehouses can be turned into decentralised warehouses, which has the following benefits: it raises the speed of the delivery, increases the flexibility of the supply chain, and optimises the warehouse operations in response to the regional demands.

2. Is a hybrid warehouse model common in modern supply chains?

Yes, hybrid warehouse designs are typical of contemporary supply chains, which are centralised and decentralised in warehouses to the advantage of optimal inventory control, balanced delivery speed, and cost-efficient supply management in diverse markets.

3. Do decentralized warehouses always guarantee faster delivery?

Not always. Although decentralised warehouses often have a higher speed of delivery, the outcome is determined by the efficiency of the distribution network, the planning of the warehouse location, and the coordination of operations of the local warehouses within the comprehensive supply chain.

4. How do centralized and decentralized systems affect risk management?

Centralised stores will have all risks in a facility, whereas decentralised warehouses will have risks spread out. Both influence the supply management resilience and continuity of operations in the warehouse in disruptions in the supply chain in a different way.