What is Supplier Evaluation and Selection?

The supplier evaluation and selection process entail the evaluation of the potential suppliers in terms of quality, reliability and compatibility with the business objectives. It combines supplier evaluation criteria, strategic sourcing and performance indicators to enhance the supply chain and supplement steady procurement plans.

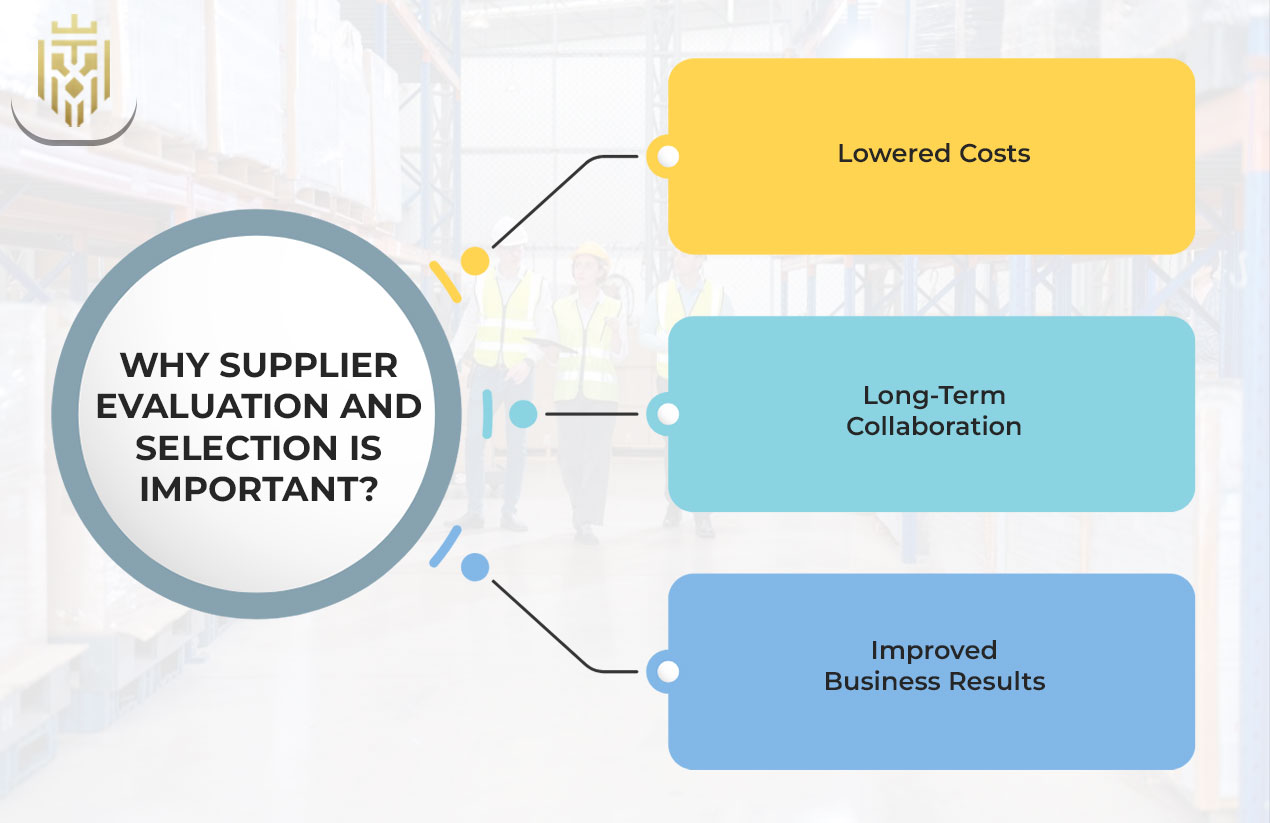

Why Supplier Evaluation and Selection is Important?

A systematic supplier evaluation process assists companies in reducing risks, improving the quality of products and increasing operational efficiency. It supports vendor management, increase supplier responsibility, and improve decision-making to ensure reliable sourcing partners and improved supply chain performance.

Lowered Costs

Through strategic supplier selection, the organisations can save on the production and logistics costs. Early supplier evaluation ensures improved pricing, efficiency, and alignment of the procurement strategy with financial and operational objectives to achieve sustainable benefits in the long run.

Long-Term Collaboration

Establishing long-term supplier relationships leads to mutual confidence, predictable supply and improved cooperation. Good supplier relationship management develops stable quality, better communication and fewer disruptions, making the companies strategize towards growth and stability.

Improved Business Results

Good supplier selection process improves customer satisfaction and production schedules as well as quality of service. Owing to the emphasis on quality business partners and decision-making based on performance, companies can increase the performance of operations, competitiveness, and profitability in the long term.

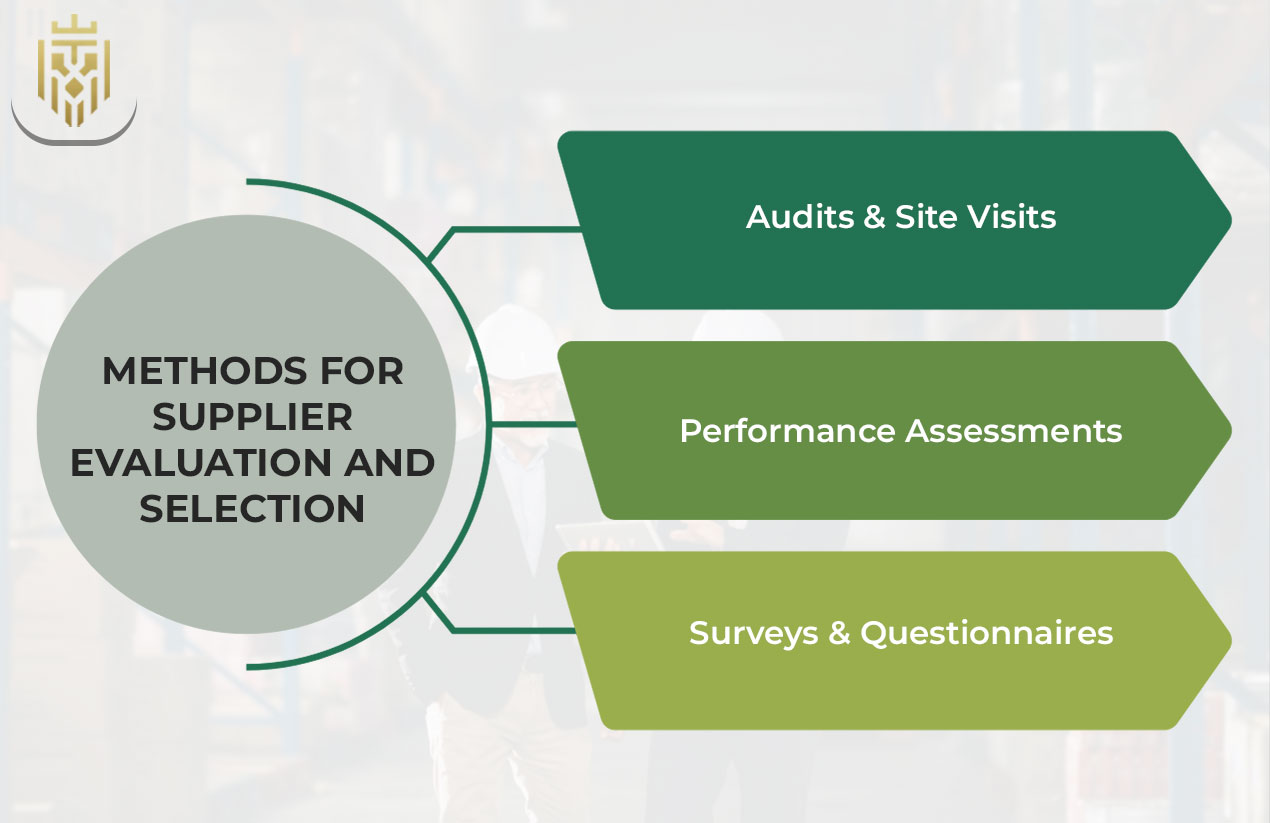

Methods for Supplier Evaluation and Selection

There are various supplier evaluation methods that are utilised by organisations to make decisions. These involve audits, surveys and performance evaluations, which determine supplier reliability, quality standards and degree of risk, making sure of good supplier relationships and successful contract management.

Audits & Site Visits

On-site inspection is useful in determining the capacity to operate, quality of products and adherence to standards. Frequent audits also enhance supplier quality management, which guarantees transparency and reduces the risks in the future by evaluating the on-ground performance accurately.

Performance Assessments

The criteria of supplier performance evaluation includes accuracy of delivery, lead times, service quality, and flexibility. These tests utilise performance metrics to determine areas of improvement, match supplier capabilities, and promote improved interactions throughout the supply chain.

Surveys & Questionnaires

The survey will give information on the capabilities of the suppliers, responsiveness and quality control. This approach is complementary to formal audits since it collects highly structured data, enables better vendor management, and refines sourcing decisions based on quantifiable and qualitative feedback.

Steps in the Supplier Evaluation and Selection Process

The steps that are involved in the supplier evaluation and selection process are structured to facilitate objective decision-making. With the help of setting the requirements and analysing the data and evaluating the suppliers, businesses develop resilient sourcing strategies and prevent possible operational risks.

Defining Requirements

The first is establishing clear supplier evaluation criteria, and such criteria involve quality standards, delivery schedules and price expectations. This establishes a platform to succeed in sourcing and also to be in tandem with business strategic objectives.

Collecting & Analysing Suppliers’ Data

By collecting financial, operational, and performance data, it is possible to make correct comparisons. This step can aid in risk assessment, and a framework of decision-making is established towards selecting the suppliers who are most suited to the organisational interests.

Supplier Identification

The identification of the appropriate suppliers is executed by mapping of the market, analysing capabilities and screening of the suppliers in respect of the pre-defined procurement strategy objectives. It makes sure that only qualified and reliable suppliers are brought to the evaluation stage.

Supplier Audit

Supplier processes, quality standards and compliance are checked by the on-site audits. This measure is necessary for supplier quality management and minimise the risks of the operation by overseeing and performing comprehensive performance audits.

Request for Quotation

Sending requests for quotations will enable businesses to shop around in terms of prices, delivery times, and service conditions. It optimises the supplier selection process, and companies end up getting the best deal and still being in control of high standards.

Final Selection

Under evaluations, the suppliers that have the best fit in strategic goals are selected by the businesses. This will guarantee stability in performance, improve supplier relationship management, as well as align with organisational sourcing strategies.

Contract Negotiation

The clear agreement agreements are negotiated and guarantee accountability and strong contract management. It establishes the standard in terms of prices, quality, schedule, and performance in order to reduce risk and build long-term partnerships.

Monitoring & Development

Monitoring of suppliers’ reliability and performance is done continuously to ensure that there is improvement. This will strengthen supplier evaluation, determine areas to develop and create long-term mutually advantageous relationships.

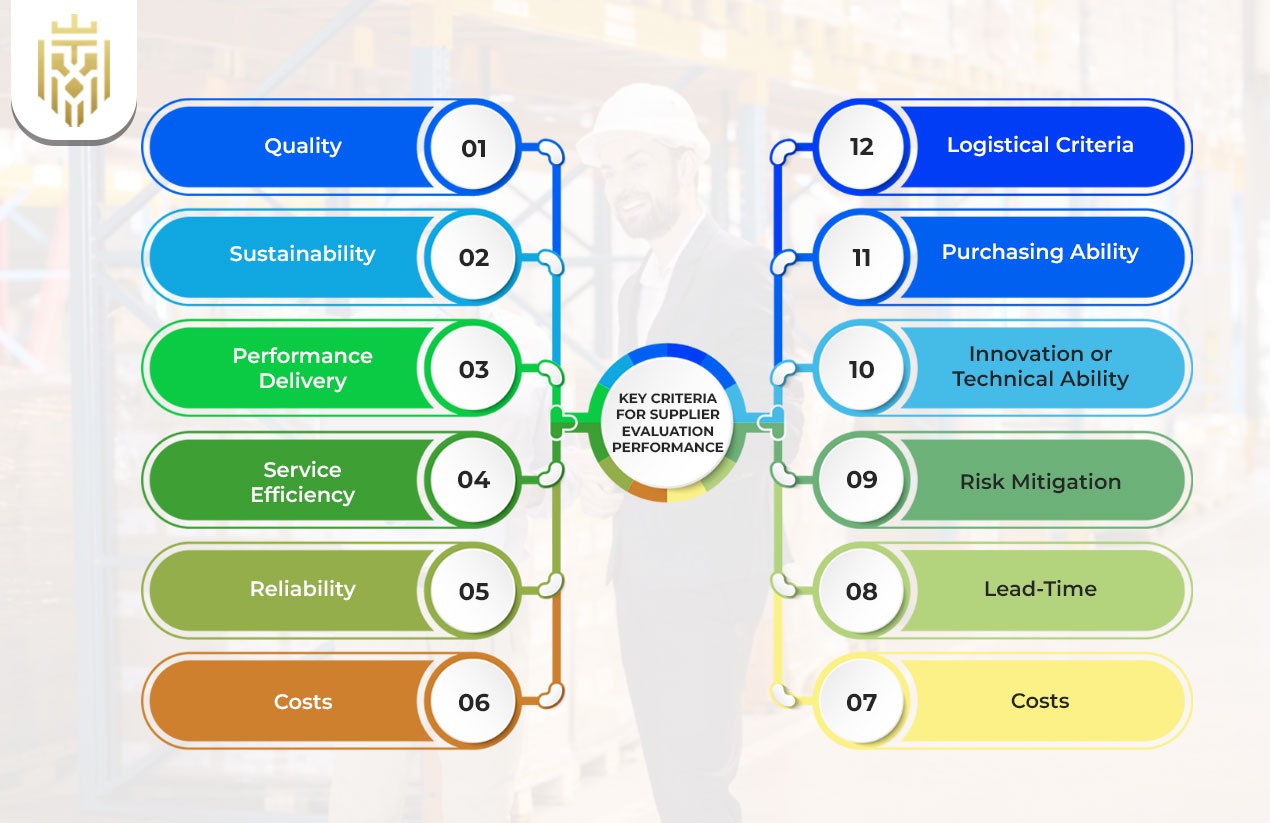

Key Criteria for Supplier Evaluation Performance

A properly designed supplier analysis and selection process considers the viable supplier analysis standards to guarantee efficiency in operations, effectiveness in cost and supply chain sustainability. The evaluation of various aspects of performance helps companies make proper judgements that can promote long-term value creation and sustained partnerships.

Quality

The element of quality is an inherent element in the task of evaluating suppliers, as it will guarantee that the products are within the specifications and standards. The quality output translates to high supplier quality management, less rework, and higher customer satisfaction, and it leads to stable operations and improved supply chain performance.

Sustainability

Responsible sourcing is done through assessing the suppliers based on environmental compliance and ethical practices. The sustainable practices reinforce the strategic sourcing, minimising the long-term expenditures and brand credibility as well as organisational sustainability objectives in the procurement strategy framework.

Performance Delivery

Consistent performance delivery improves consistency of operation and customer satisfaction. The latter is an essential component of supplier performance analysis, where timely delivery, responsiveness, and capacity alignment assists in keeping the workflows running and reduce the delays of key processes in the security supply chain.

Service Efficiency

Service efficiency compares the responsiveness of a supplier to demands. It enhances better management of vendors through streamlined communication channels and timely solutions and minimises downtime, and businesses can cope with the complexities of the supply chain more dynamically.

Reliability

The reliability of the supplier is an imperative in continuity and stability. Effective partners have a stable performance, fulfil obligations, and contribute to risk evaluation efforts, which allow companies to reduce the impact of disruptions and establish more robust sourcing relationships in the long term.

Costs

Cost evaluation entails the comparison of pricing arrangements, financial effects in the long run and value-added benefits. It helps in the strategic selection of suppliers, as it ensures that it targets the budget, operational efficiency and sustainability in terms of financial performance without losing quality.

Lead-Time

Lead-time assessment is based on the speed at which suppliers can deliver deliveries. The use of shorter lead times leads to improved inventory planning, procurement strategy, and flexibility of changing market needs.

Risk Mitigation

Supplier assessment involves risk mitigation to determine potential vulnerability in the sourcing. Through significant risk assessment, businesses will increase the supply chain resilience and minimise operational and financial unpredictabilities associated with supplier performance.

Innovation or Technical Ability

The evaluation of the innovation and technical capability is a way to make sure that suppliers can meet the changes in the requirements. The high level of technicality aids in the assessment of the suppliers, promotes the enhancement of the processes, and provides the businesses with the competitive advantage in the form of the modern solutions.

Geographical Location

The location of suppliers has an impact on logistics expenses, the delivery schedules and responsiveness. Assessment of location criteria will enhance efficiency in transport and will assist in the management of contracts that are in line with the operational strategies and distribution channels.

Purchasing Ability

Assessment of buying capability will guarantee that the suppliers can be scaled as per the business requirements. It allows supplier relationship management to match capacity, responsiveness, and dependability to fluctuating market circumstances and purchase demands.

Logistical Criteria

Logistical assessment pays attention to the ability to transport, store and distribute. A proper integration of logistics with supply chain operations helps improve service delivery and also continuous operation across various sourcing points.

Best Practices in Supplier Selection Process

Structured frameworks, adoption of technology and transparency are advantageous in the supplier selection process. Adherence to best practice will lead to proper evaluation, enhanced long-term relationships with suppliers and improved alignment of suppliers with the objectives of the business to achieve operational excellence and sustainability.

Leverage Technology

Digital solutions enhance openness and precision in the evaluation process of suppliers to allow automated evaluation and tracking of performances. This results in improved decision-making, effective vendor management, and effective sourcing strategies that result in improved productivity.

Maintain Transparency

Openness fosters good faith and responsibility within the relationship with suppliers. Proper communication and expectations that should be clearly communicated encourage good contract management, which minimises disagreement and enhances conformity between suppliers and operational and compliance objectives.

Standardise Supplier Evaluation Criteria

The fact that there are common supplier assessment criteria is a guarantee of good comparisons and decision-making. It assists in the streamlining of processes, minimises bias and aids strategic alignment in the sourcing structure of the organisation.

Prioritize Long-Term Supplier Relationships

The establishment of long-term collaboration with suppliers brings about trust. This will help achieve a common growth, enhance supplier trustworthiness, and better outcomes in performance throughout the supply chain ecosystem.

Involve Cross-Functional Teams

Using various teams in decision-making will provide a better evaluation of suppliers. The cross-functional cooperation enhances the understanding, reinforces risk analysis, and gives certainty that supplier decisions do not contradict operational and strategic objectives.

Continuously Review and Adapt

Sourcing strategies are kept up to date by regularly revising and updating supplier practices. It promotes constant betterment, improves management of supplier relationships, and keeps pace with the changing market requirements and performance standards.

FAQs

1. How often should suppliers be re-evaluated in an active supply chain?

Suppliers need to be reassessed once or twice a year based on a structured supplier evaluation criterion to make sure that performance, reliability, quality, and mitigation of risks are in tandem with business and supply chain objectives.

2. Does supplier evaluation criteria differ by industry?

Yes, supplier evaluation criteria differ depending on industry requirements based on regulatory requirements, product complexity, quality standards and delivery expectations, which ensures customised evaluation based on operations and strategic sourcing requirements.

3. What role does technology play in supplier evaluation?

Technology makes the supplier evaluation process easier by allowing real-time performance monitoring, automated assessment, and data-driven insights, which fosters more accurate and faster and more transparent supplier selection and supplier monitoring processes.

4. How do supplier audits improve the evaluation process?

Supplier audits enhance supplier performance review through checking ground practices, compliance, quality systems and reliability to provide precise information that would aid informed procurement strategy and improved risk management.

5. How do companies balance multiple suppliers for the same product?

The companies manage a balance between suppliers by strategic sourcing, performance measurement, and supplier relationship management, which means cost competitiveness, minimisation of risk exposure, and continuity of operations throughout the entire chain of supply.