What is A Business Continuity Plan?

A business continuity plan is a documented detailed with procedures and instructions that keeps the logistics operations going for companies even in times of crisis. To explain what is a business continuity plan briefly, it is a structured strategy that minimises disruptions, maintains supply flow, and protects stakeholder trust, forming the backbone of resilient logistics networks worldwide.

Why Must Logistics Prioritize Business Continuity?

Logistics disruptions could paralyse international trade, and therefore, ensuring continuity is paramount. Business continuity planning is done to minimise delays, safeguard contracts, and ensure operational recovery. Such a proactive approach enables companies to keep goods flowing even in the case of encounters or emergencies.

Safeguard Goods Flow

There are natural disasters, cyberattacks, or strikes that can disrupt logistics flow. A business continuity plan in cybersecurity is essential to prevent IT breakdowns that disrupt tracking systems. Companies have resilient safeguards that guarantee that shipments are delivered to their destinations without affecting time, safety, and customer commitments.

Build Trust Through Preparedness

Trust builds when partners observe companies that are ready to face crises. A robust business continuity plan and disaster recovery plan complement each other, ensuring both operations and data remain secure. This dual protection instils customer, supplier, and stakeholder confidence in any logistics chain.

Core Business Continuity Elements

A logistics continuity plan requires clarity of operations, documented routes, secured systems, and exercised recovery procedures. Business continuity planning focuses on resilience, supply flow, and risk preparedness. The adoption of these elements produces organisations that can provide steady service even during disruptive events worldwide.

Map Routes & Backups

Planning of main logistics routes and having alternative routes available when the main routing is disturbed will ensure no stoppage of operations due to disruptions. A business continuity plan allows companies to adapt to blocked passageways, destruction of infrastructure, or isolation of areas quickly, ensuring that critical shipments continue to pass across networks without any disruption.

Assess Risks with BIA

Business Impact Analysis (BIA) assists in prioritising important logistical functions. It helps companies identify operational dependencies, financial exposure, and customer commitments. This systematic evaluation will help organisations to invest in the processes that maintain business value in unexpected events and risks.

Implementing Safeguards and Alternatives

Operational resiliency is accomplished through procedures like having redundant systems, backup fleets, and fortified facilities. Through structured risk frameworks, business continuity planning is done for stabilising essential logistics tasks and providing alternatives that prevent total disruption when unforeseen challenges affect supply chain performance.

Diversifying Suppliers and Carriers

The use of one supplier or carrier makes the company’s logistics dependent. A business continuity plan promotes flexibility through diversification of vendors and routes. This option minimises the risks of dependency, enhances bargaining power, and protects the cargo in case of economic turmoil, geopolitical tension, or an unexpected ban on transport.

Defining Roles & Communication

Specific roles, designated responsibilities, and a channel of communication keep responses timely. Leaders who know why do you need a business continuity plan understand that it aligns staff, reduces confusion, and enables coordinated recovery, protecting organisational credibility during operational crises or unforeseen global interruptions.

Continuity in Third-Party Deals

Agreements with third parties should describe crisis responsibilities. Integrating a business continuity plan and disaster recovery plan into supplier agreements ensures seamless collaboration, faster recovery, and minimised losses, strengthening reliability while safeguarding the entire logistics chain during regional or global disruptions.

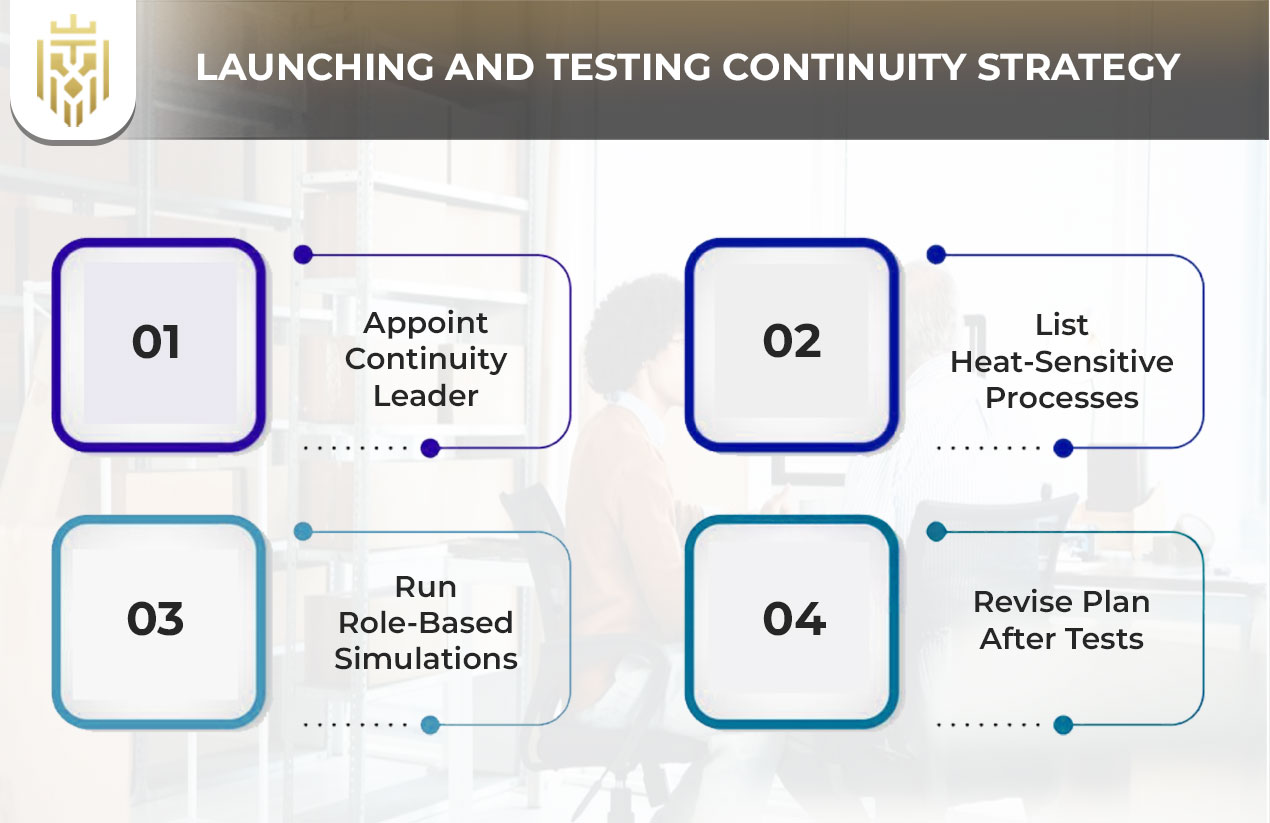

Launching and Testing Continuity Strategy

Initiating continuity strategies means deciding about leadership, diagramming sensitive processes, and practising. The answer to what is a business continuity plan also extends to continuous testing. Professional updating makes the strategy flexible, and the logistics companies will remain resilient as new threats appear in the world.

Appoint Continuity Leader

Any continuity system needs leadership. The appointment of a logistics continuity leader provides accountability, training and enforcement of policies. Their knowledge ensures the business continuity plan is definitely aligned with the operating requirements, bringing about speedier recovery, which is also efficient and totally integrated into the logistic culture of the organisation.

List Heat-Sensitive Processes

The tolerance mapping process requires identification of the critical logistics operations, including but not limited to perishable goods, pharmaceuticals, IT applications and compliance-related activities. A business continuity plan in cybersecurity ensures monitoring systems remain functional, protecting data integrity and safeguarding supply chain resilience under disruptions.

Run Role-Based Simulations

Simulation drills equip teams with real-life crisis preparedness. By clarifying the business continuity plan’s meaning, organisations ensure staff understand priorities, act promptly, and reduce recovery delays. Role-based drills enhance coordination and build confidence in managing the disruptions in case of actual emergencies.

Revise Plan After Tests

Testing and changes in business evolve continuity strategies. Business continuity planning focuses on identifying weaknesses and updating responses. Frequent revision keeps strategies current, minimising weaknesses and keeping logistics firms ready to evolve as supply chains change in response to market or regulatory demands or environmental forces.

Advantages of a Strong Continuity Plan

A robust business continuity strategy provides logistics companies with strategic resilience. It reduces risks, enhances operational standardisation, and improves credibility in the market. This allows customers and partners to be confident in the firm that foresees disruptions to sustain reliable long-term relationships and consistent performance despite unexpected global or local threats.

Cut Downtime Quickly

Fast recovery reduces operating losses. Since business continuity planning is done for minimising downtime, structured action protocols guarantee faster decision-making. Logistics teams will be able to restore deliveries quickly, sustain order flows, and safeguard contractual commitments, avoiding extended delays that can impair financial stability and reputation.

Ensure Reliable Deliveries

Consistent deliveries build brand trust. By embedding a business continuity plan and disaster recovery plan, logistics companies can guarantee goods arrive even during crises. This trust creates customer loyalty in the long run, which shows that the organisation prizes stability in any environmental, geopolitical, or technological crises.

Gain Contract Advantage

Organised companies have advantages in negotiations. Resilience ensures that logistics companies are desirable business partners because they have a documented business continuity plan. Clients appreciate this reliability, which offers a competitive advantage, greater credibility, and bargaining power when bidding with competitors in global supply chains who may be less prepared.

Boost Reputation & Trust

Stakeholders give preference to partners who always plan. Leaders know that it plays a role in safeguarding reputation, financial stability, and institutional trust throughout operations. An effective, well-constructed framework demonstrates responsibility, which helps build confidence with customers, suppliers, regulators, and long-term investors.

FAQs

1. What defines a continuity plan tailored to logistics?

A logistics continuity plan will focus on the continuity of supply chains and will focus on mapped routes, second carriers, risk assessments, and quick recovery plans specifically focused on goods movement and delivery assurance.

2. What logistics-specific threats should it cover?

It should concern natural catastrophes, cyberattacks, industrial actions, transportation failures, regulatory interference, and supplier failures. Every threat has a direct effect on scheduling delivery, so continuity planning is essential to keep the global logistics system functioning reliably.

3. Which processes in logistics need top priority?

Shipments subject to time limits, cold chain management, compliance-related documentation, and IT tracking are essential priorities. These operations maintain customer confidence, profitability, and business stability in the event of unforeseen logistics issues or stoppages.

4. How often should operational teams run continuity drills?

Continuity drills should be conducted on a biannual basis by operational teams. Regular simulations serve to ensure preparedness, reveal gaps, enhance team coordination, and keep continuity plans current as logistics change.

5. How does continuity planning give logistics firms an advantage?

Continuity planning creates resilience, mitigates downtime, protects contracts, and enhances reputation. Negotiating logistic disruptions, logistics firms can gain competitive advantages in negotiation, customer confidence, and long-term relationship building.